WS750: The NEW Resistance Welding Control

Introducing the WS750

The Next Generation of Resistance Welding Control

We have just launched the new WS750, a cutting-edge microprocessor-based resistance welding control designed to revolutionize the welding industry. With 100 programmable JOBs, an intuitive interface, and advanced monitoring capabilities, it grants an incredible welding experience.

Now Available in Leading Resistance Welding Machines

The WS750 control will now be available in CEA’s renowned resistance welding machines, including:

✔ Z-ZP

✔ K-KP

✔ PPS-PPN

✔ BSW

This integration ensures enhanced control, precision, and efficiency across various resistance welding applications.

Key Advantages and Features of WS750

The WS750 is packed with features that enhance precision, efficiency, and quality control. Here’s why it stands out:

-

User-Friendly Interface

- The WS750 features three displays, six keys, and LED indicators, making it easy to configure and monitor the welding process. The LEDs provide real-time feedback on the welding cycle status.

-

Two Configurations: STANDARD and ADVANCED

-

- The STANDARD version manages all key parameters for spot welding applications.

- The ADVANCED version includes welding current and time measurement for quality control, pre-heating and post-heating time and current functions, plus an optional proportional valve for precise force adjustments.

-

-

Advanced Welding Process Control

- Full control over parameters such as pre-squeeze, welding time, cooling, pulse intervals, and post-heating.

- Ability to recall two consecutive programs (ideal for complex applications).

- Current limit monitoring ensures consistent weld quality.

-

USB Connectivity & Data Management

-

- Backup and restore welding JOBs.

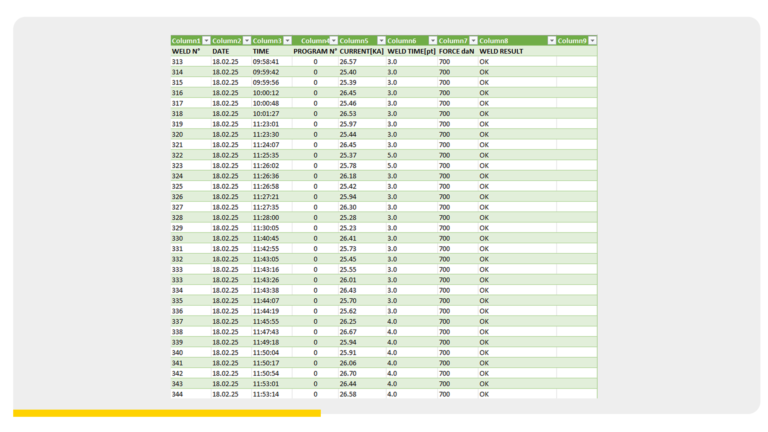

- Export welding logbooks in Excel format for easy analysis.

- Simplified firmware updates via USB.

-

-

Seamless Integration & Safety Features

-

-

- Compatible with external PLCs for streamlined automation.

- Supports error monitoring and messaging, keeping operators informed.

- Mains voltage compensation ensures stable performance in varying power conditions.

-

Example of report loaded into EXCEL from file stored in USB memory stick.

Ideal Applications

The WS750 is designed for spot, projection, and butt welding, making it a perfect fit for industries requiring high-quality welds with repeatable accuracy. It is ideal for:

- Automotive manufacturing

- Sheet metal fabrication

- Appliance production

- General metalworking

Why Choose the WS750?

If you're looking for a reliable, high-performance welding control that improves productivity and quality, the WS750 is the perfect solution. With its advanced features, intuitive operation, and robust data management, it provides a future-proof investment for welding professionals.