Plasma cutting

SHARK 55-M

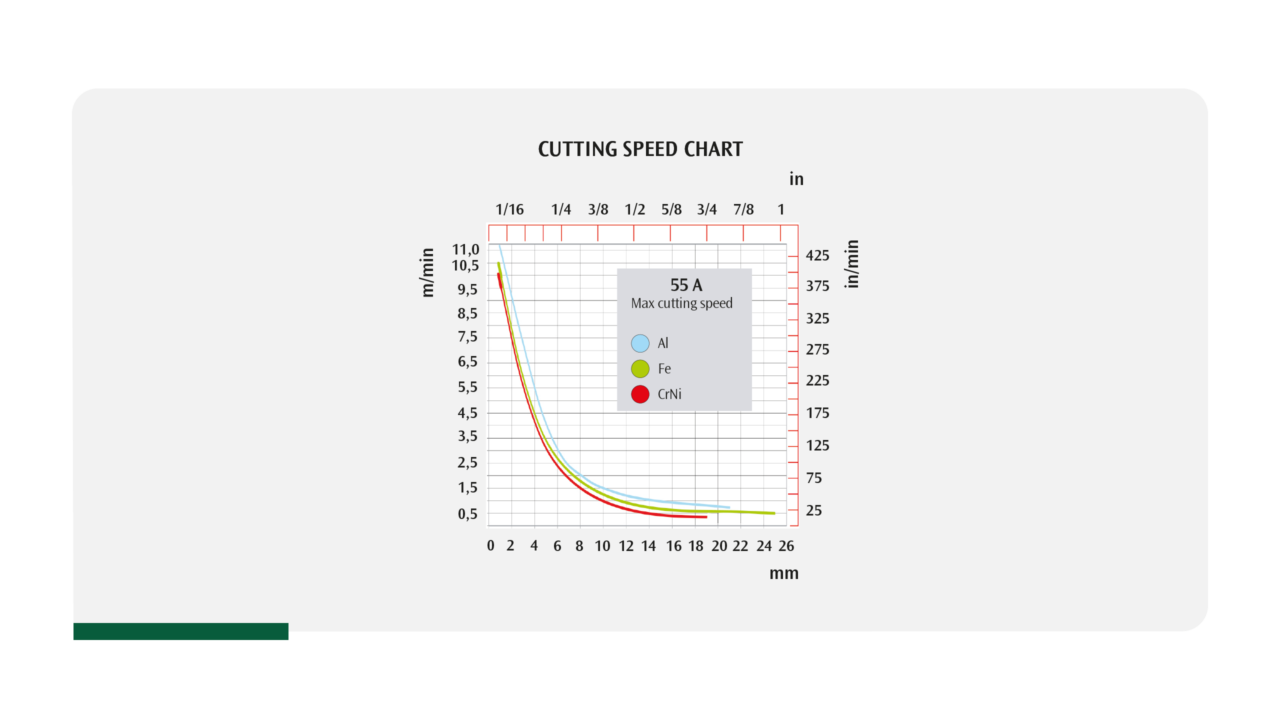

PLASMA CUTTING 55 A

SHARK 55 M is the most efficient solution to fully meet the cutting needs of medium and light fabrication work

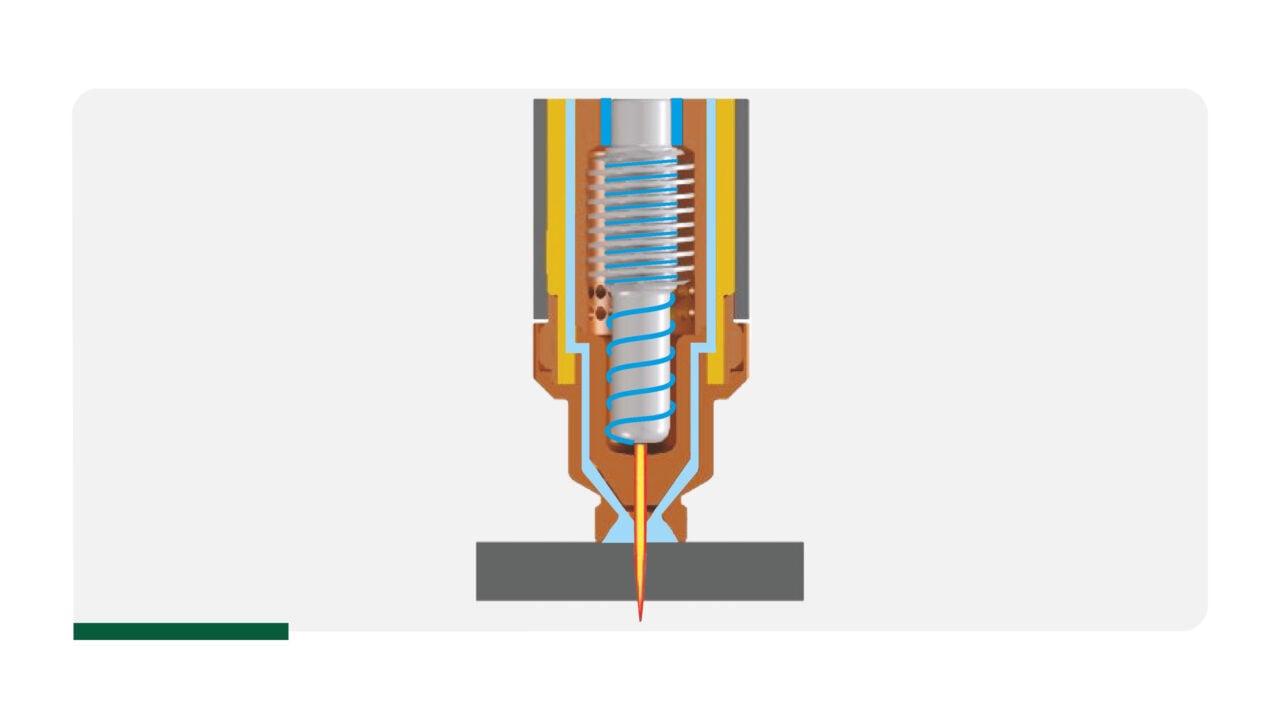

Powerful and compact, SHARK 55-M is the most efficient solution to fully meet the cutting needs of medium and light fabrication work. Its always precise cutting performance enables the achievement of the highest standards in all circumstances. Top quality cutting is achieved at high speed thanks to SKM75 HPC High-Performance-Cutting technology torch, which offers a powerful and concentrated cutting beam.

Main benefits

- SKM75 torch with HPC High Performance Cutting technology and coaxial cable

- Powerful, compact and light, only 15 Kg

- More productivity thanks to high quality and cutting speed

- Reduced operating costs granted by longer

life of the consumable parts

Other characteristics

- Electronic control for an excellent cutting quality

- Professional high flow air circulation

- Pilot arc torch

- Possibility of cutting grids and perforated lamination sheets

- Contact cutting possibility

- “Energy Saving” function to operate the power source cooling fan only when necessary

- Cutting parameter stability within ±15% mains voltage fluctuations

- Shockproof and dustproof control rack protection cover

- Electric protection on the torch for the maximum safety of the operator

Available accessories

Discover all available accessories

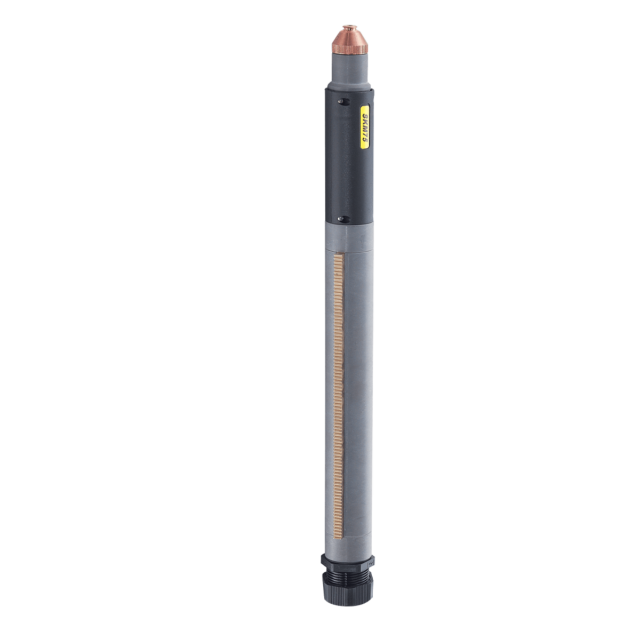

SKM 75 6m

Machine Straight Torch SKM 75 6 m 70 A with gear rack

SKM 75 12m

Machine Straight Torch SKM 75 12 m 70 A with gear rack

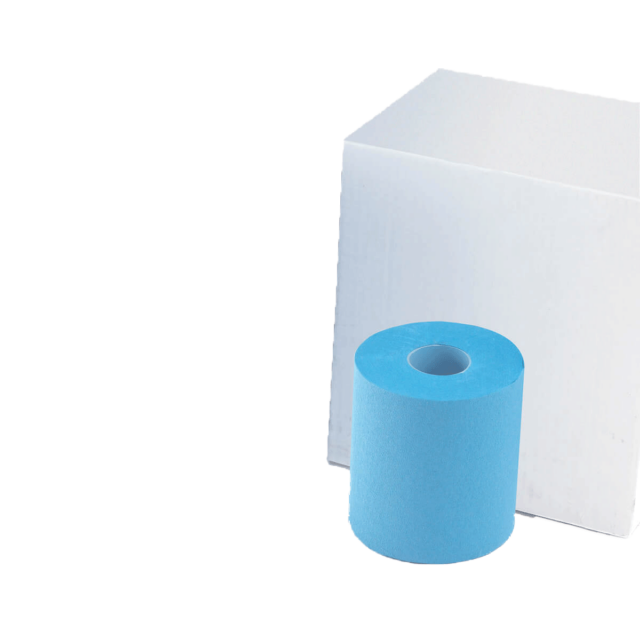

Compressed air filter

Compressed air filter

Filter cartridges

Filter cartridges package of 4 pcs

Gallery

SHARK 55-M at work

Datasheet

SHARK 55-M: Technical features

| TECHNICAL DATA | SHARK 55-M | ||

| Input Voltage 50/60 Hz | V | 400-3ph | |

| Input Power @ I2 max | kVA | 10,5 | |

| Delayed Fuse (I2 @ 100%) | A | 10 | |

| Power Factor / cos φ | 0,63/0,99 | ||

| Efficiency Degree | % | 85 | |

| Current range | A | 20 ÷ 55 | |

| Duty Cycle (40°C) | 100% | A | 35 |

| 60% | A | 45 | |

| 40% | A | 55 | |

| Motorgenerator requirement for full capacity | kVA | 16 | |

| Cutting Capacity | Quality | mm | 12 |

| Production | mm | 15 | |

| Maximum | mm | 20 | |

| Piercing | mm | 12 | |

| Cutting Power | KW | 6,8 | |

| Gas supply | Air / N2 | ||

| Gas Pressure | bar | 5,0 – 5,5 | |

| Gas Flow | l/min | 170 ÷ 190 | |

| Protection Class | IP | 23 S | |

| Dimensions (LxWxH) | mm | 390 | |

| Weight | kg | 15 | |

Configurator

Configure SHARK 55-M for your needs

Select product

Select product

Included

Accessories (multiple choice available)

Consumables (multiple choice available)

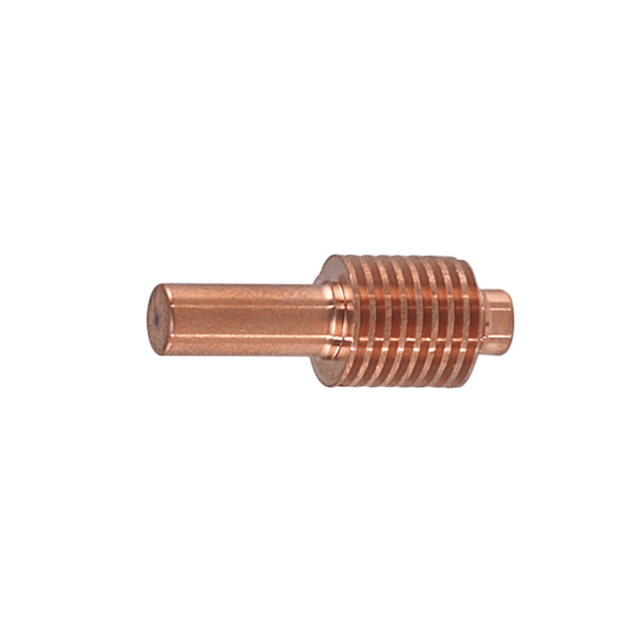

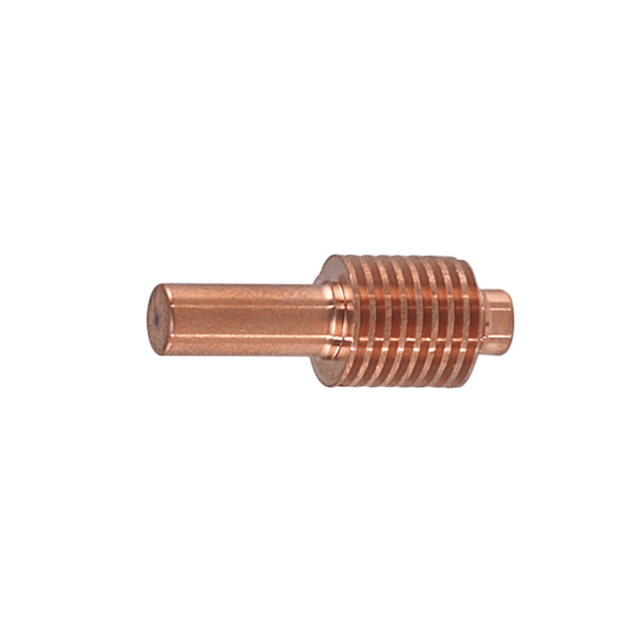

Consumables

Electrode 5pcs

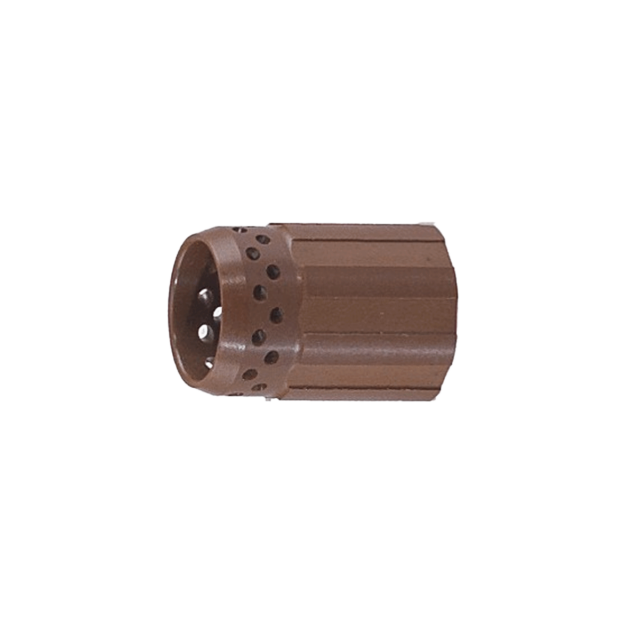

Consumables

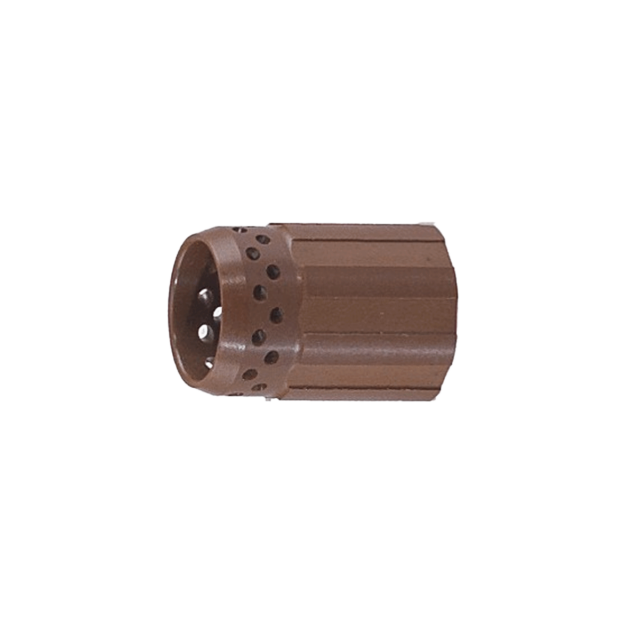

Swirl ring 2pcs

Consumables

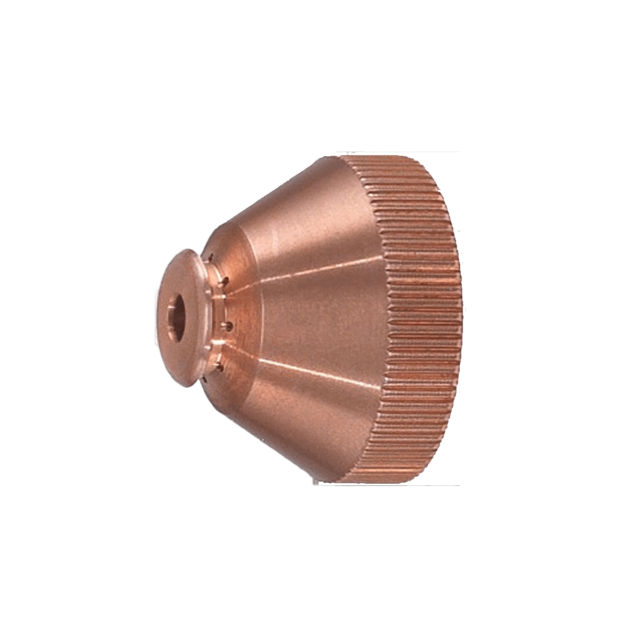

Nozzle 50 A 10pcs

Consumables

Nozzle 70 A 10pcs

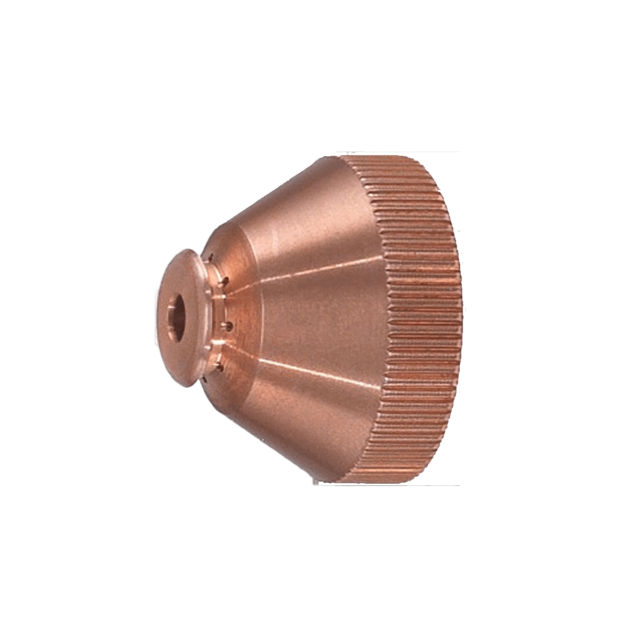

Consumables

External nozzle 1pc

Consumables

External nozzle ohmic sensor 1pc

Consumables

Shield cap 2pcs

Select product

Included

Included

SKM 75 12m

Accessories (multiple choice available)

Accessories

Trolley CTP 10

Accessories

Compressed air filter

Accessories

Filter cartridges

Consumables (multiple choice available)

Consumables

O-ring 20pcs

Consumables

Electrode 5pcs

Consumables

Swirl ring 2pcs

Consumables

Nozzle 50 A 10pcs

Consumables

Nozzle 70 A 10pcs

Consumables

External nozzle 1pc

Consumables

External nozzle ohmic sensor 1pc

Consumables

Shield cap 2pcs