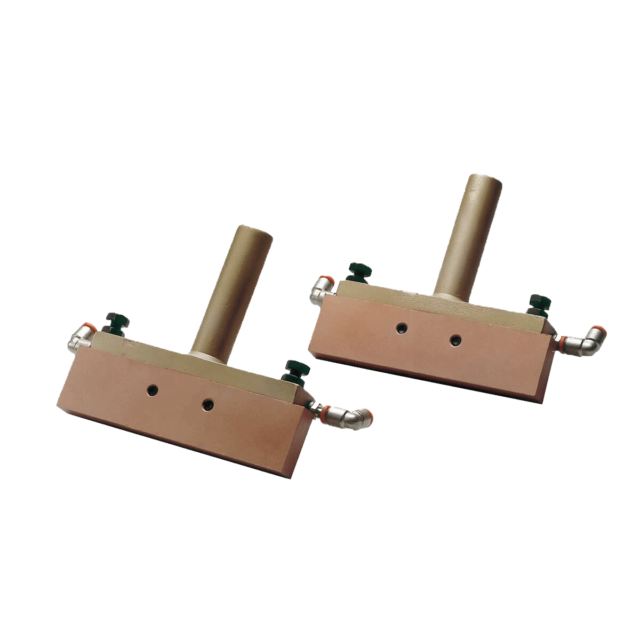

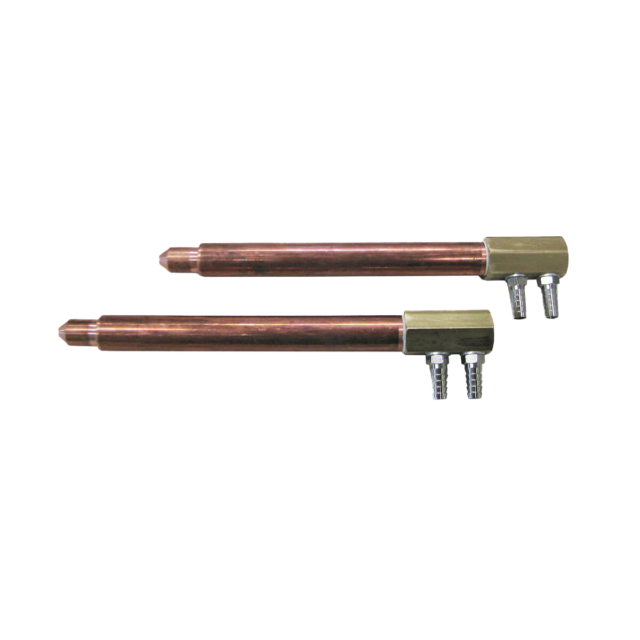

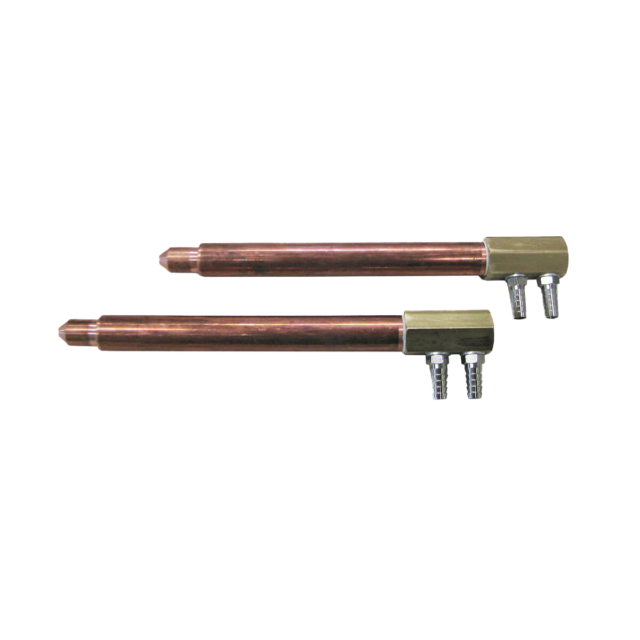

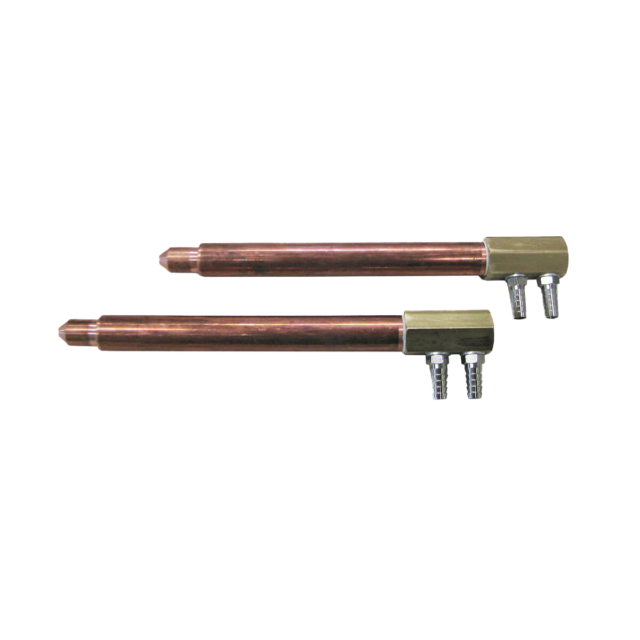

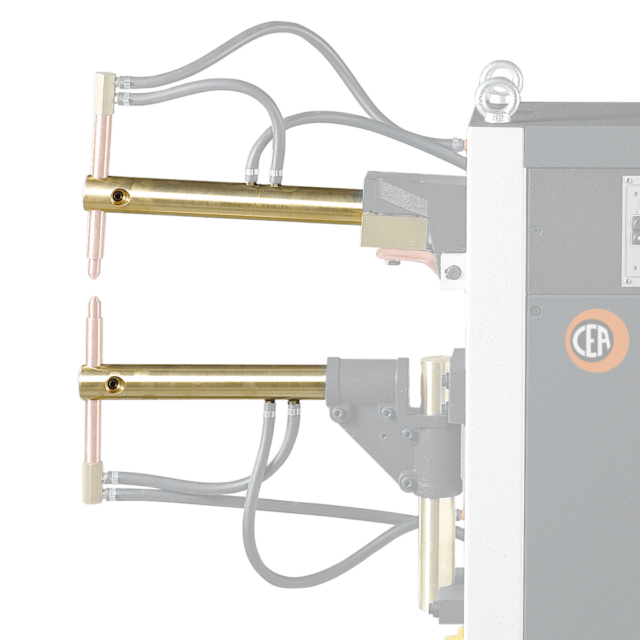

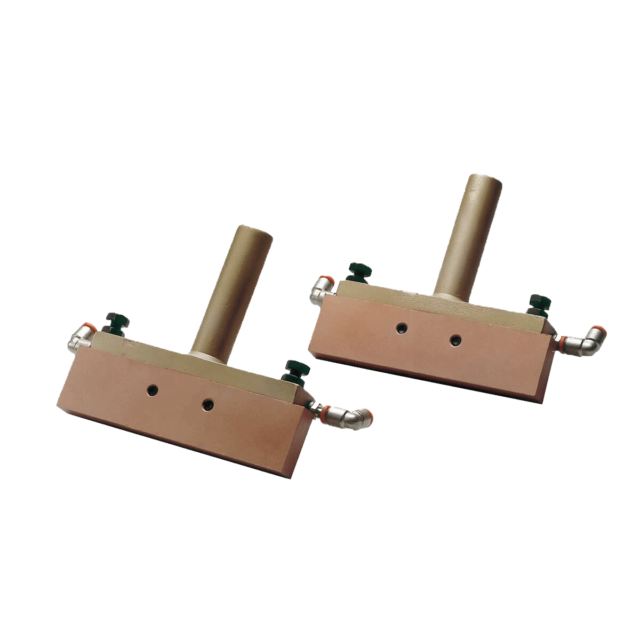

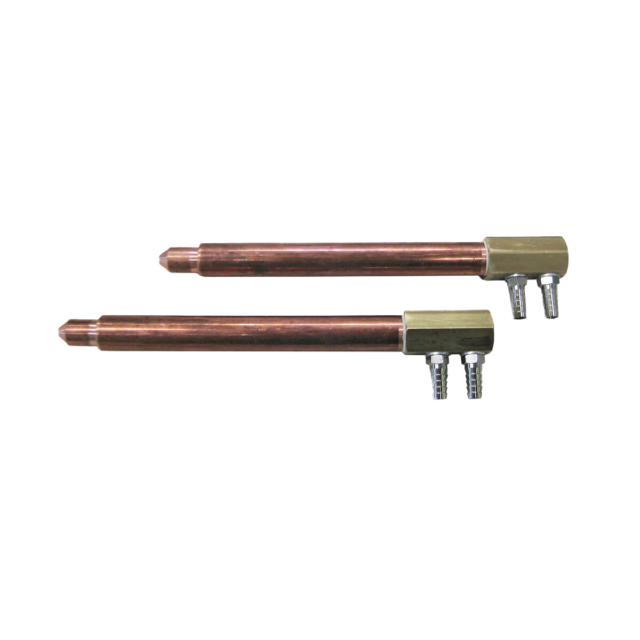

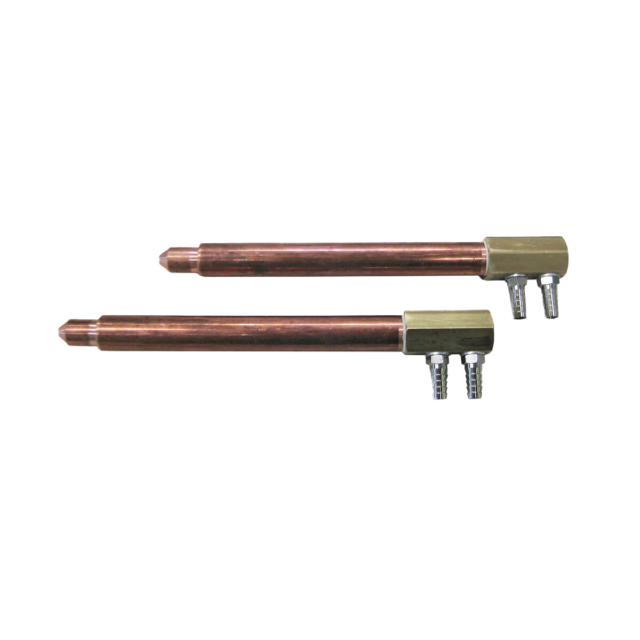

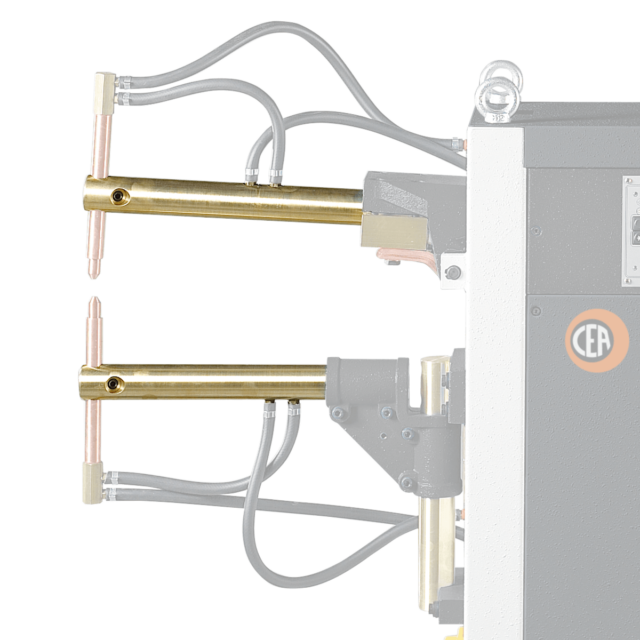

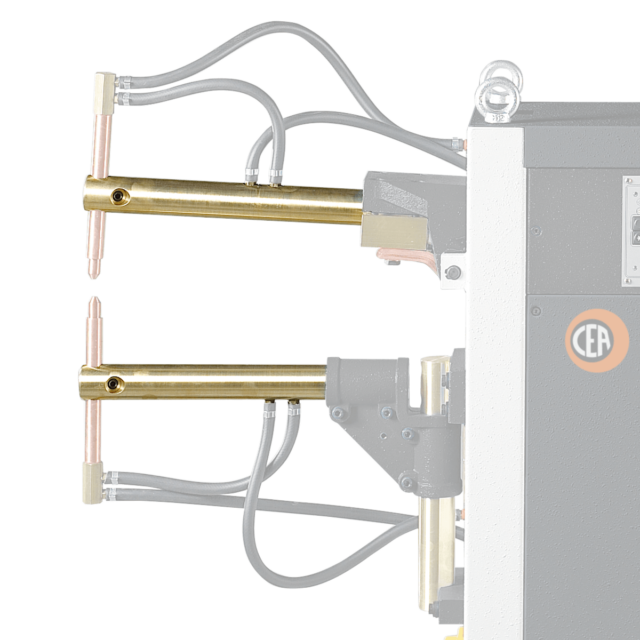

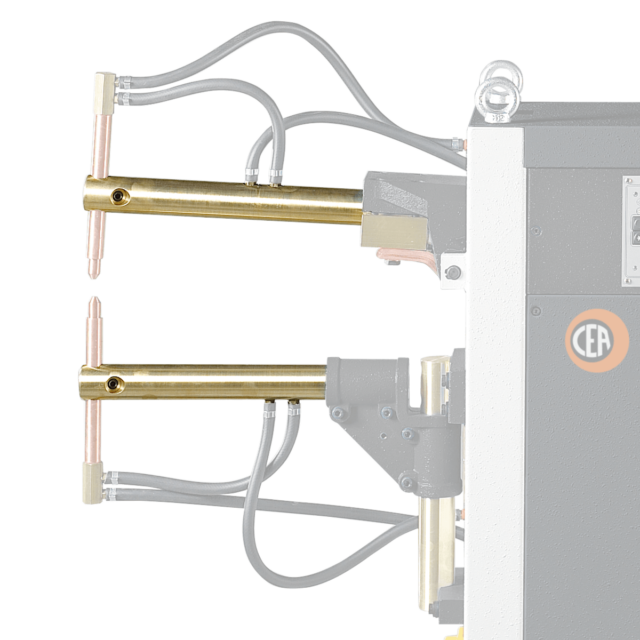

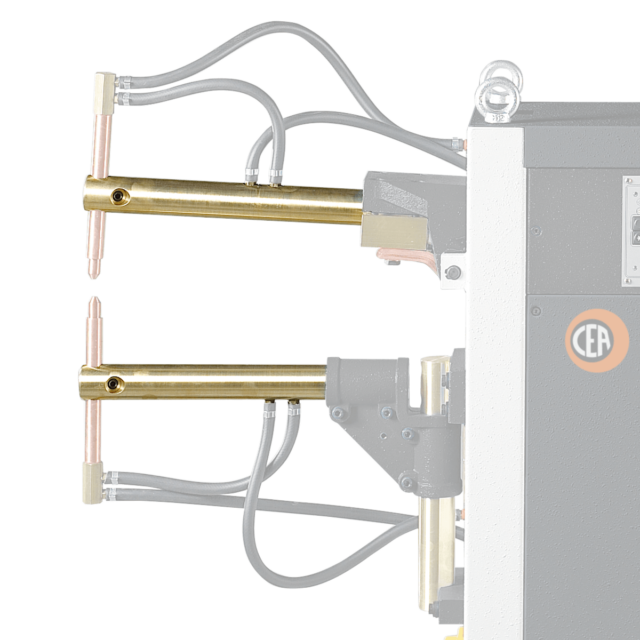

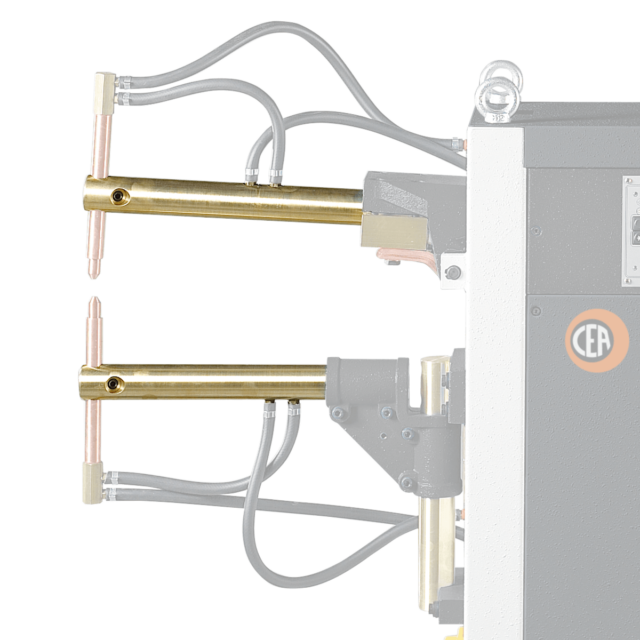

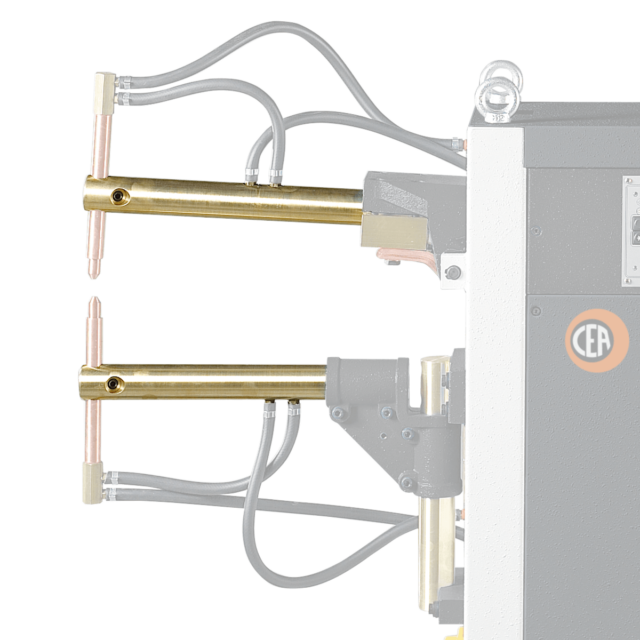

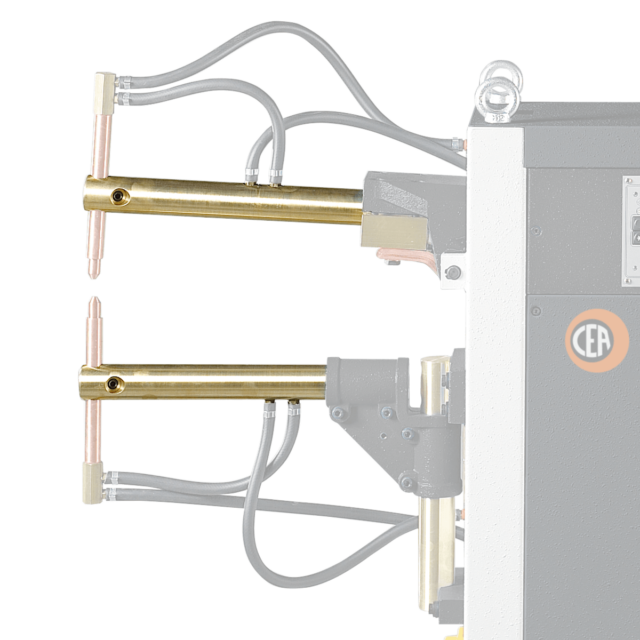

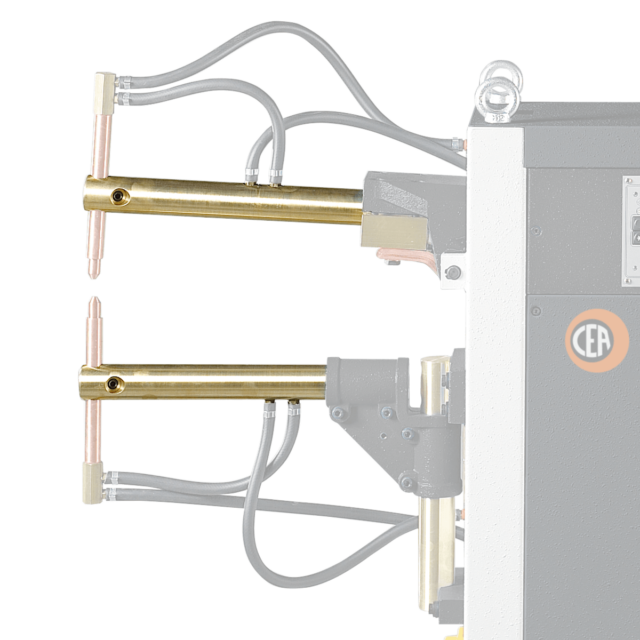

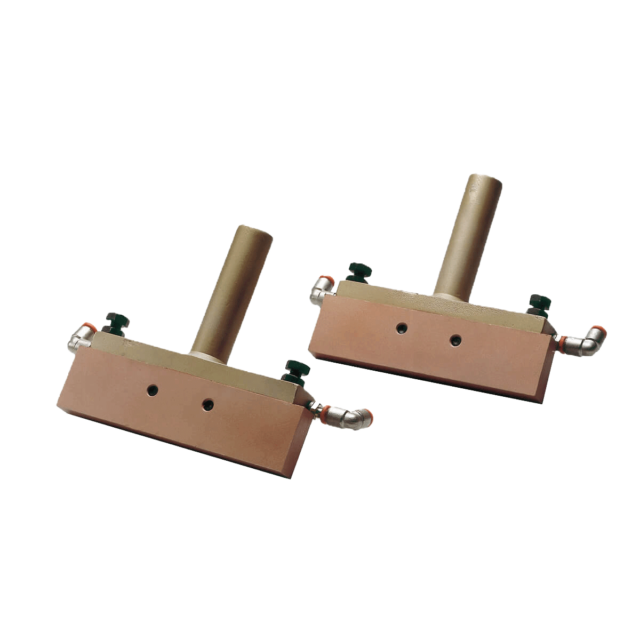

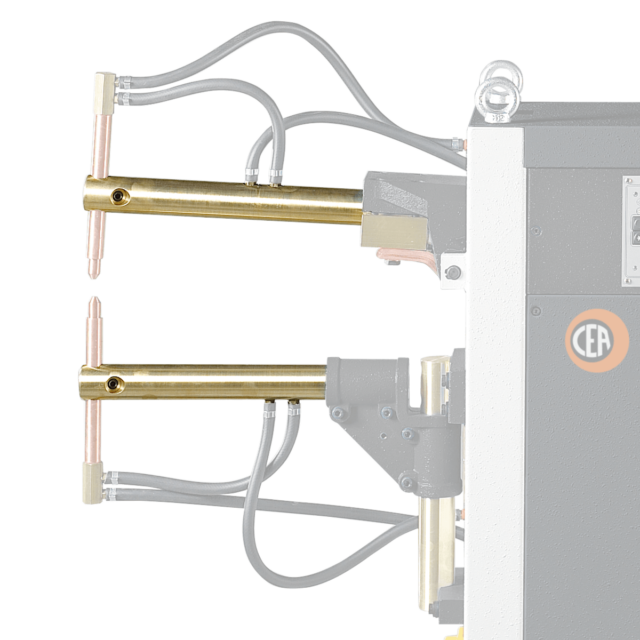

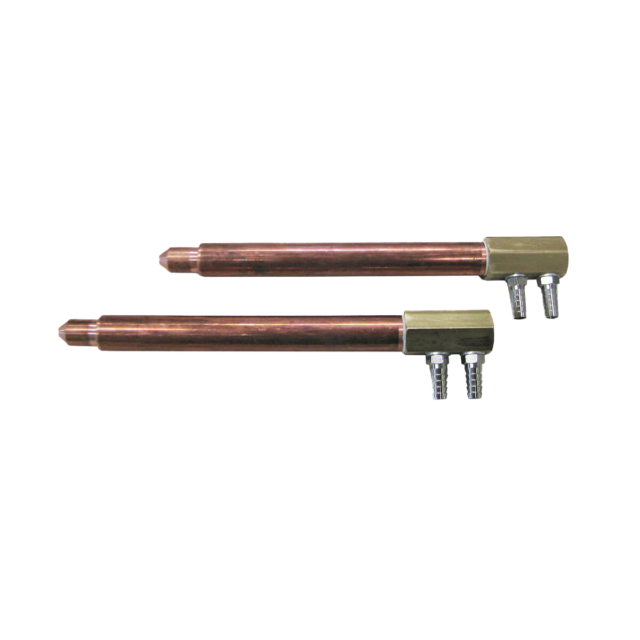

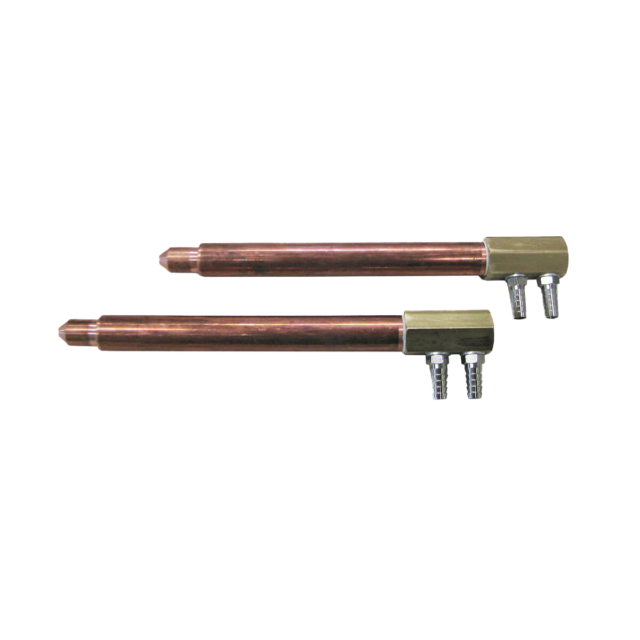

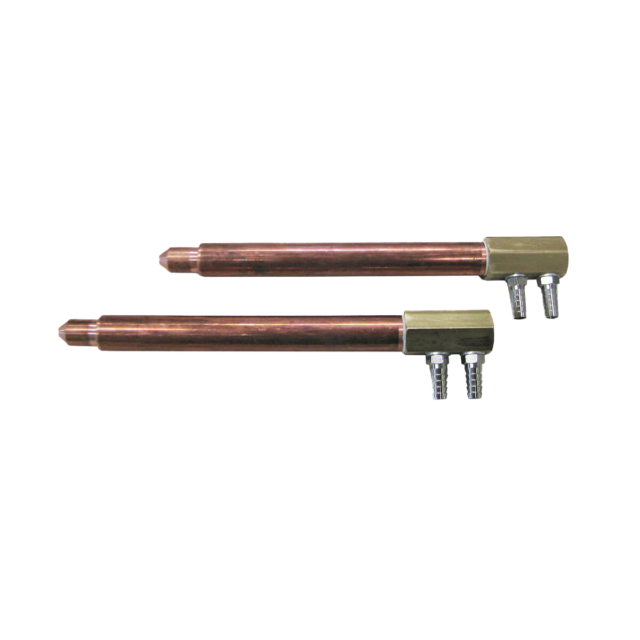

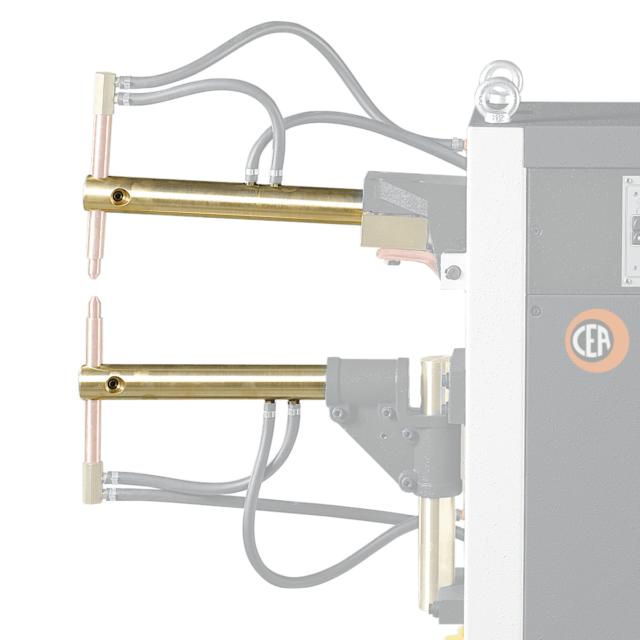

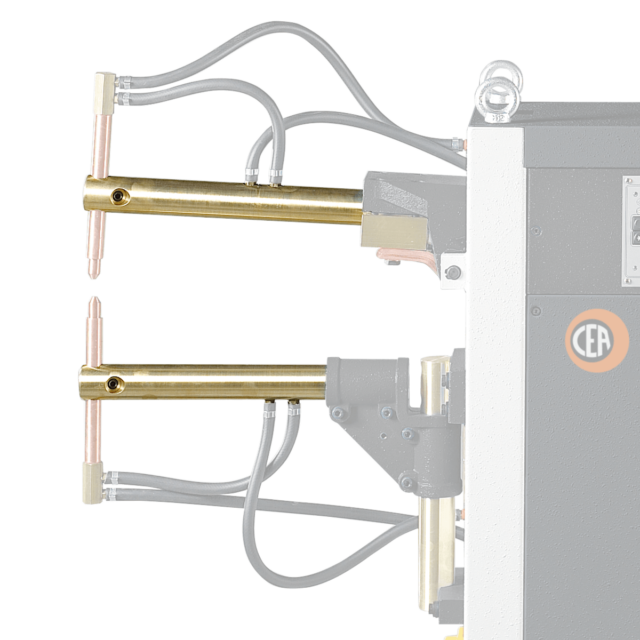

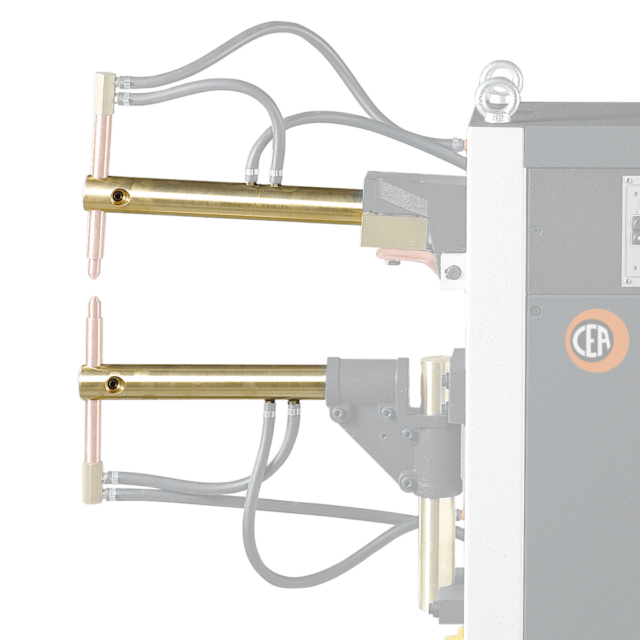

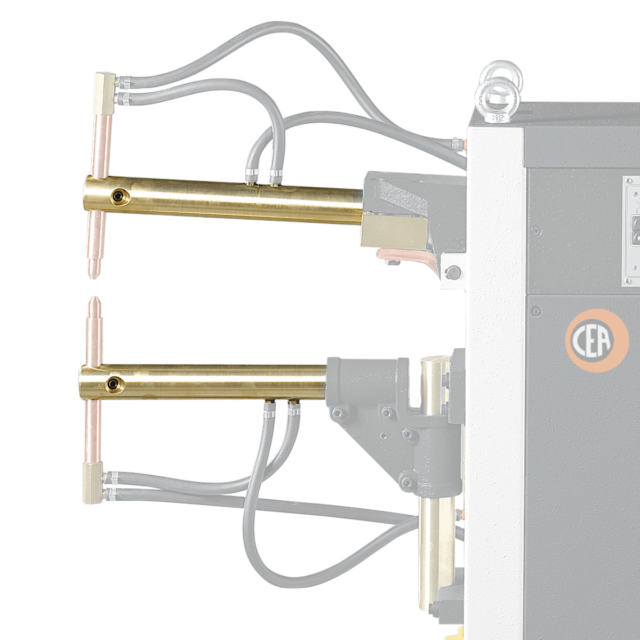

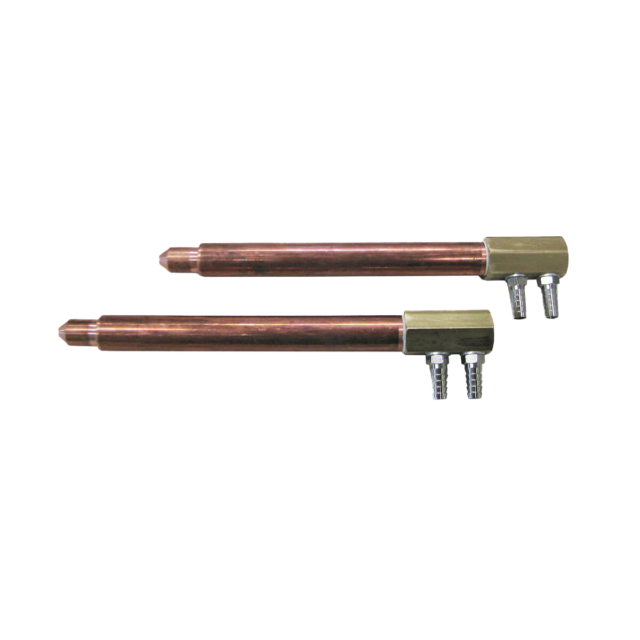

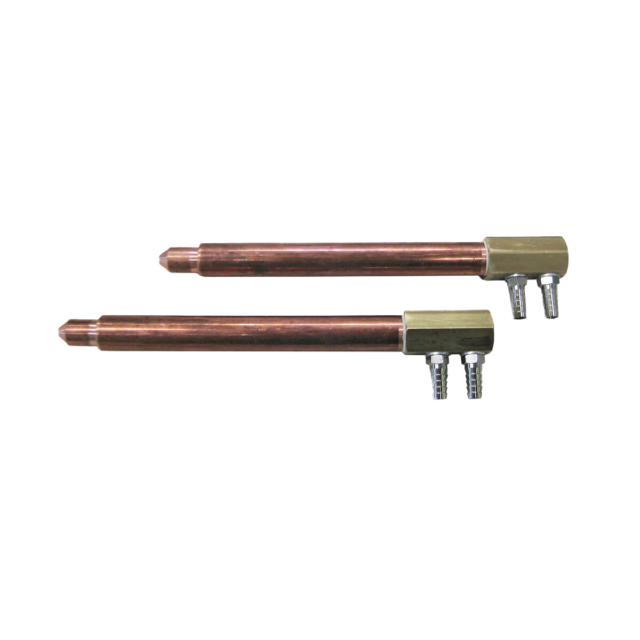

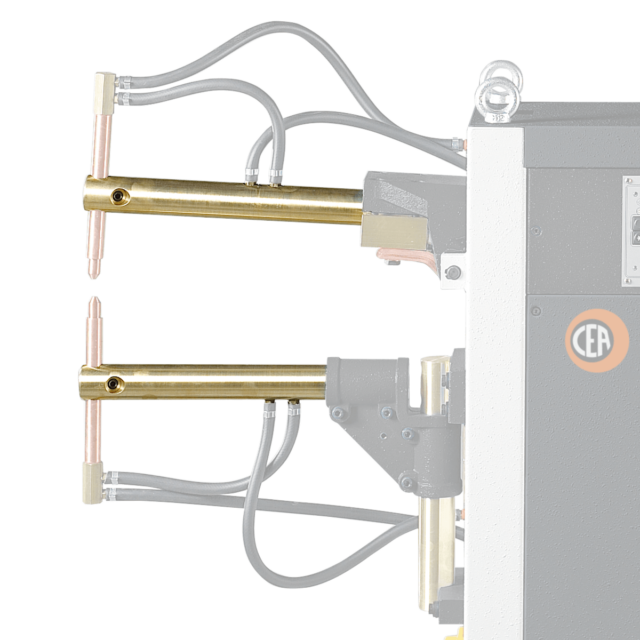

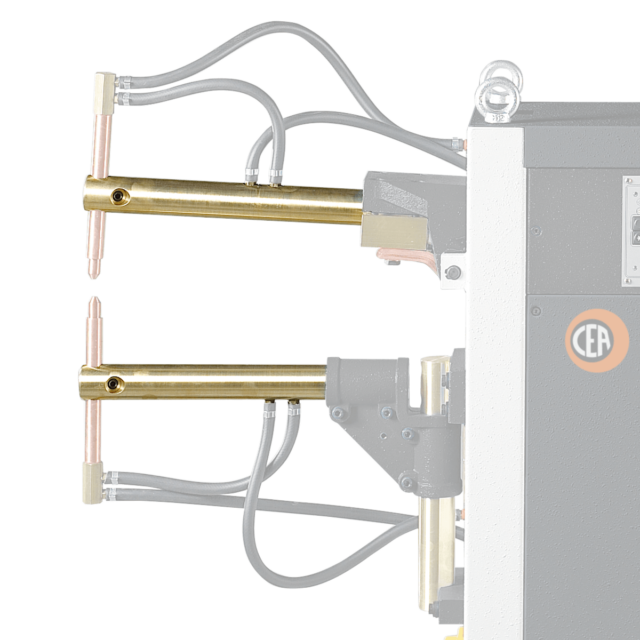

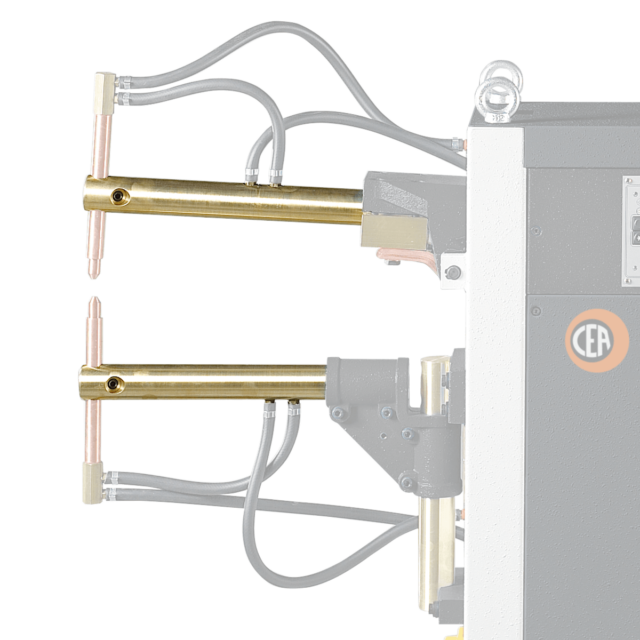

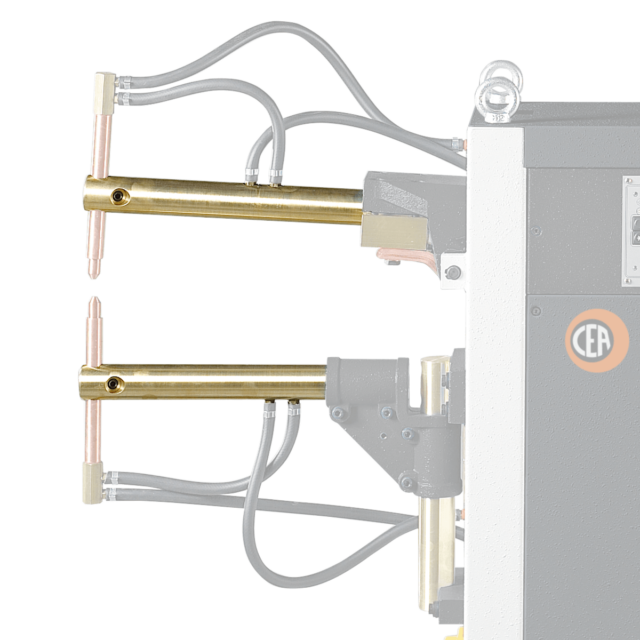

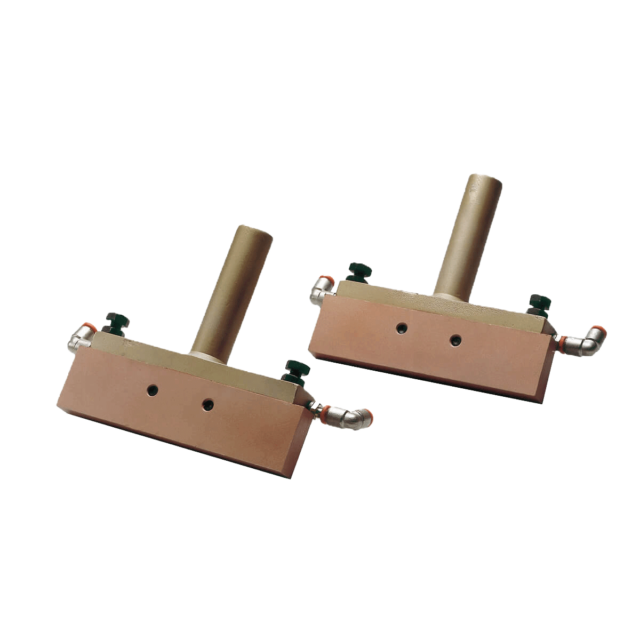

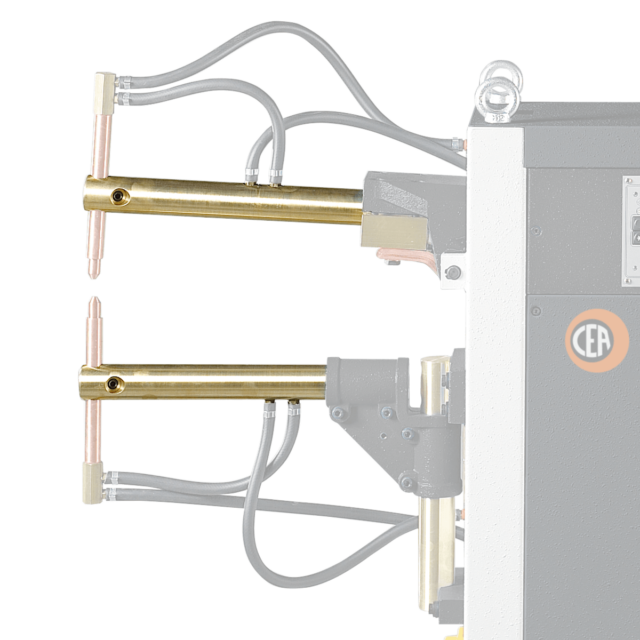

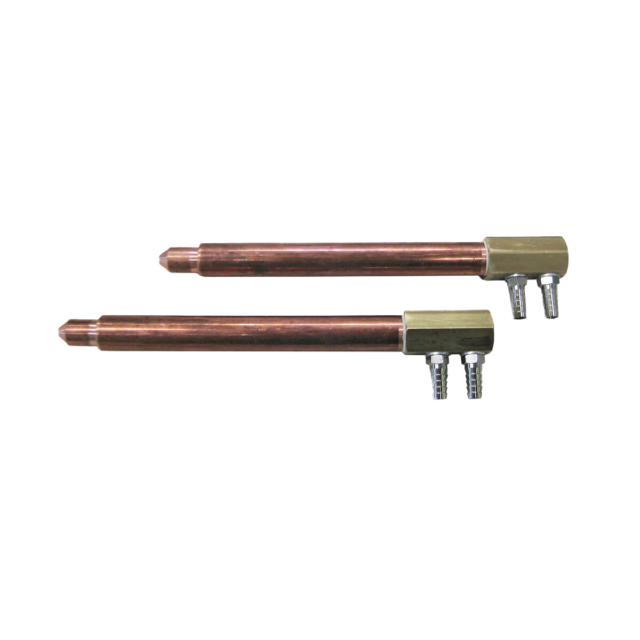

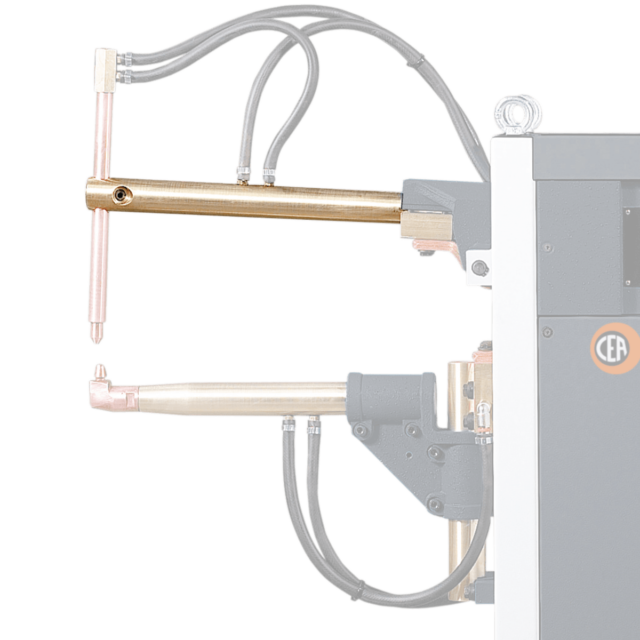

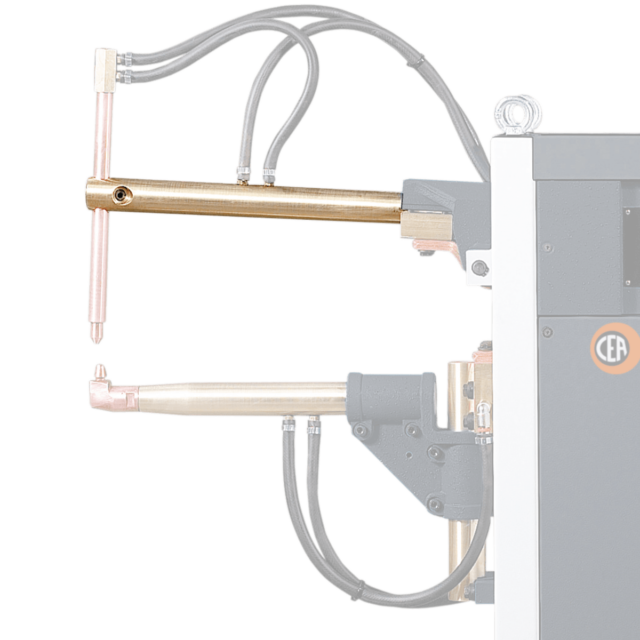

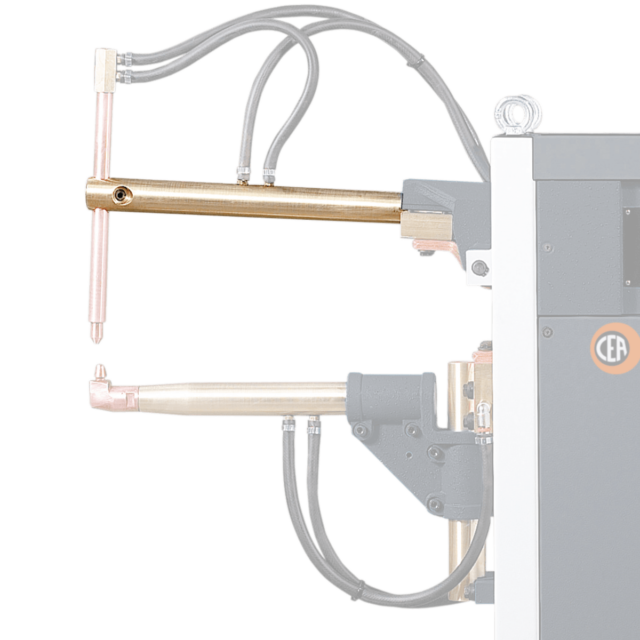

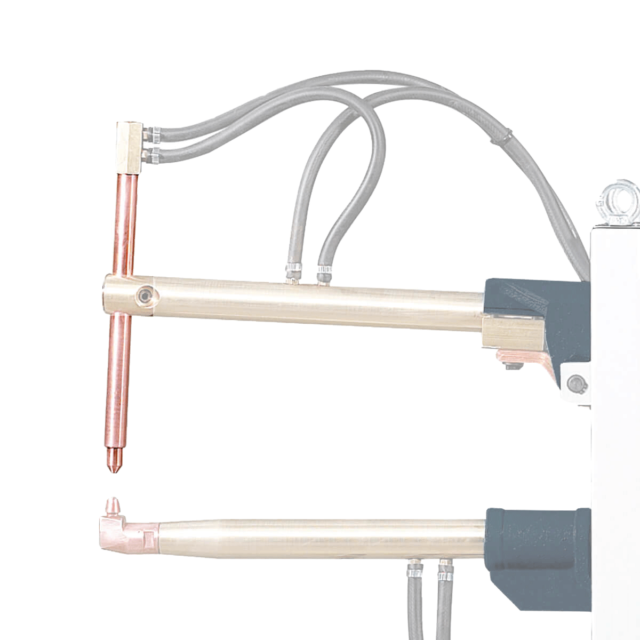

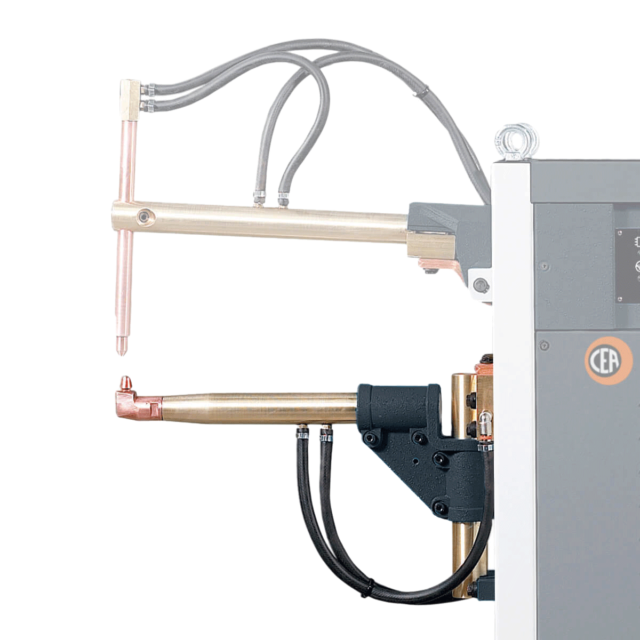

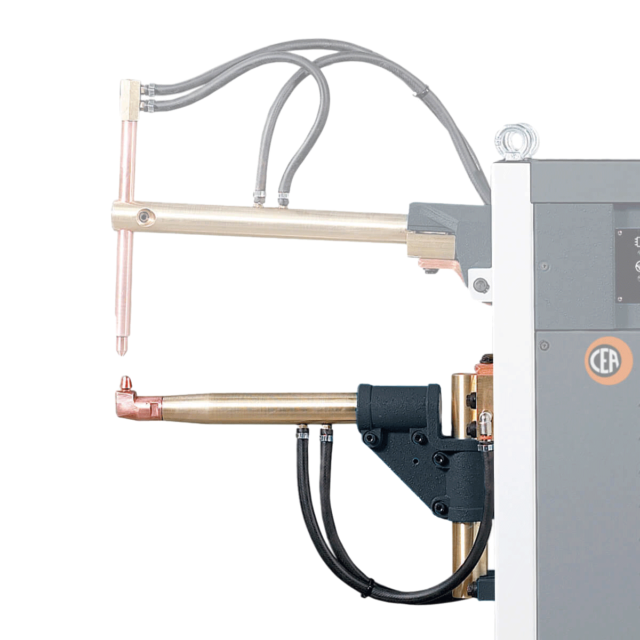

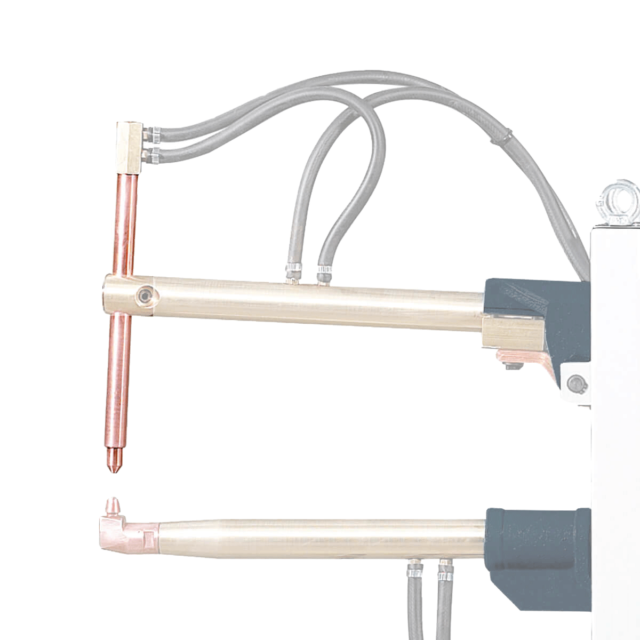

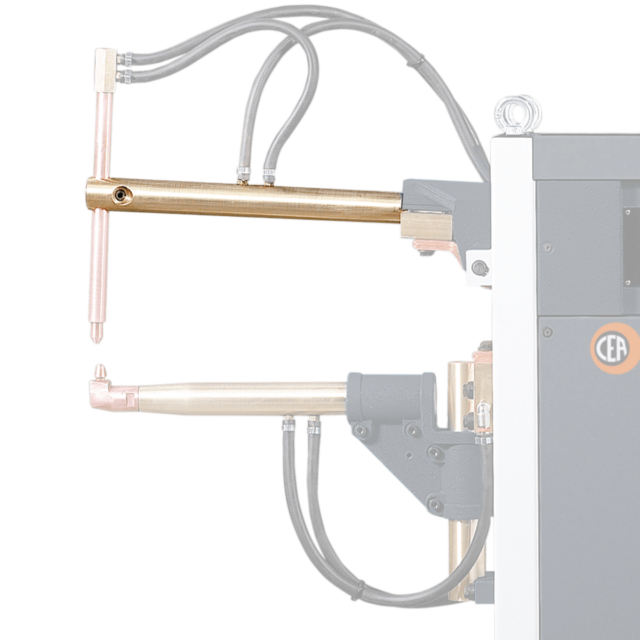

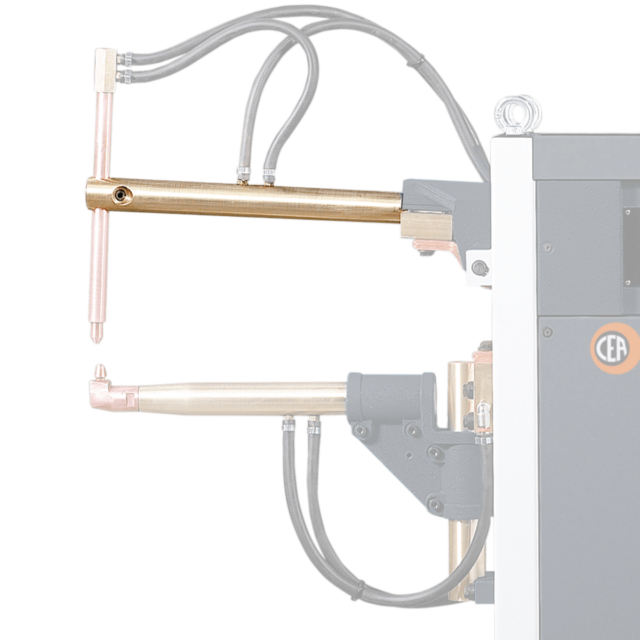

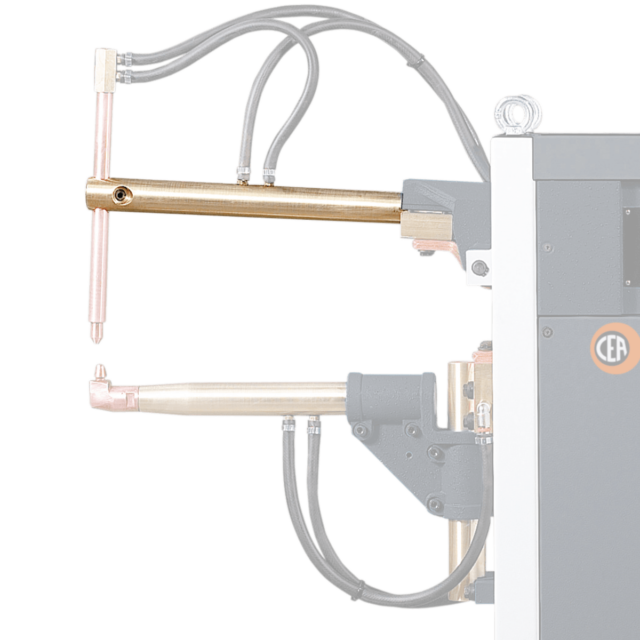

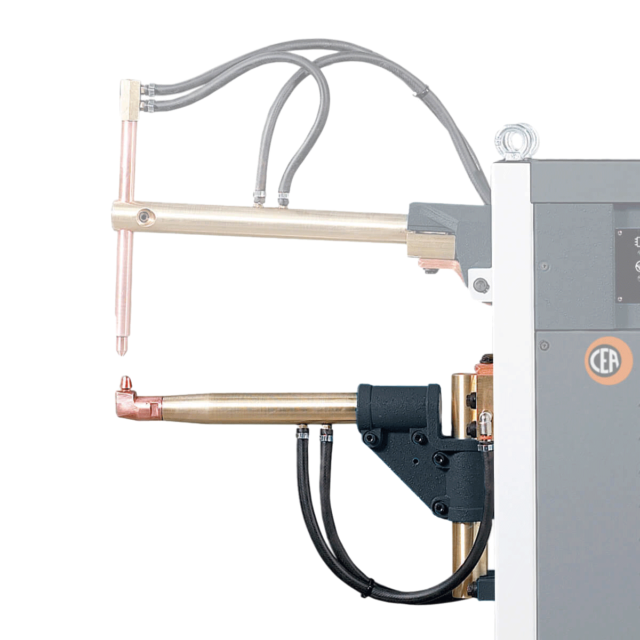

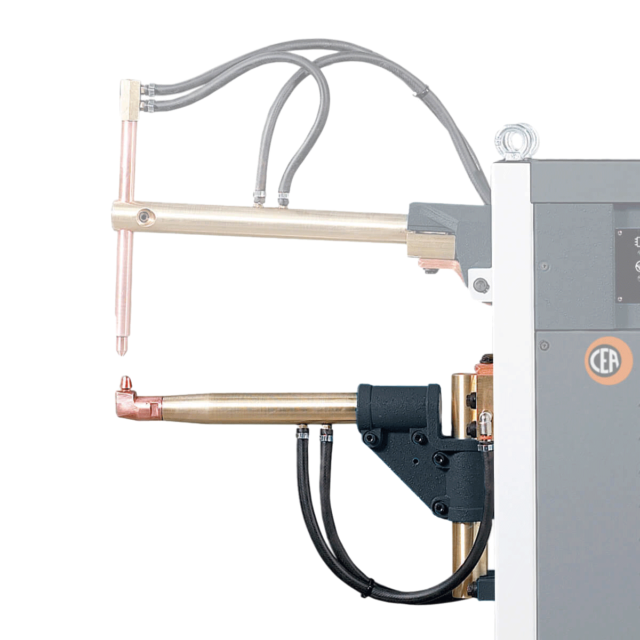

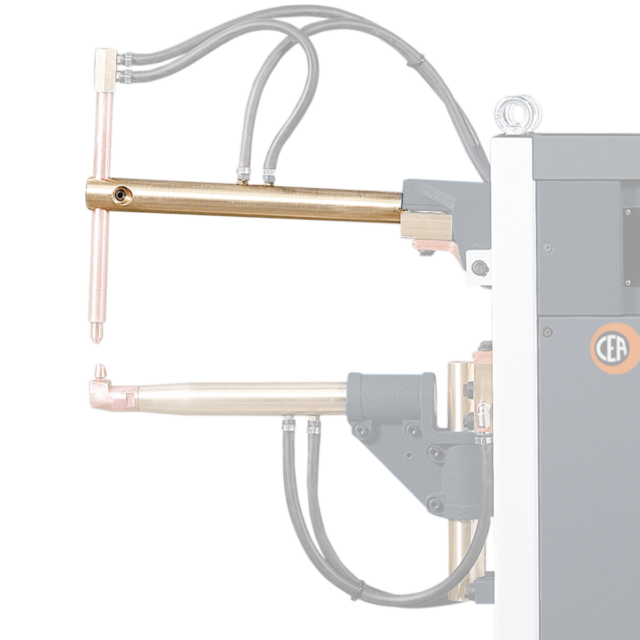

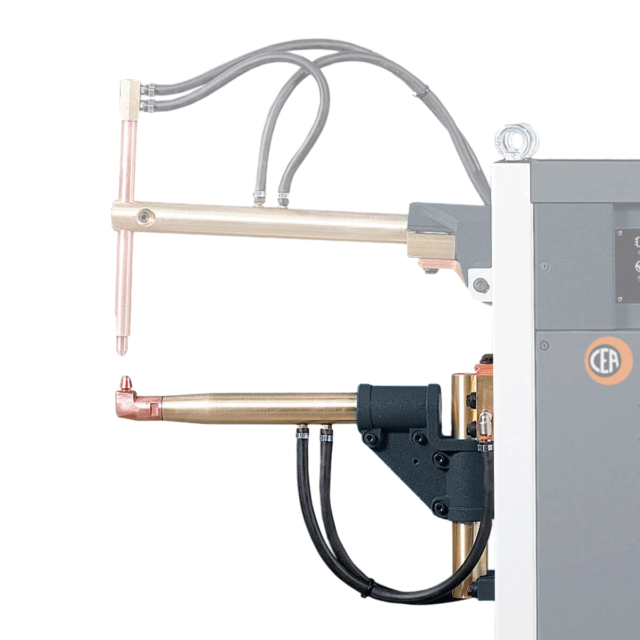

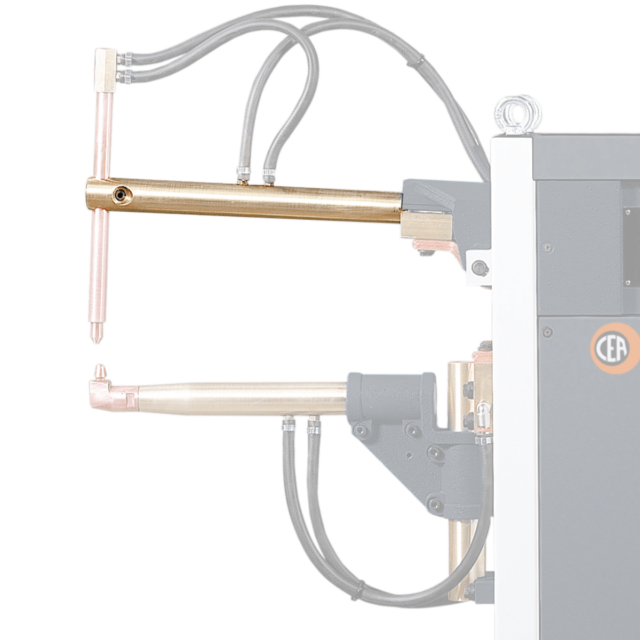

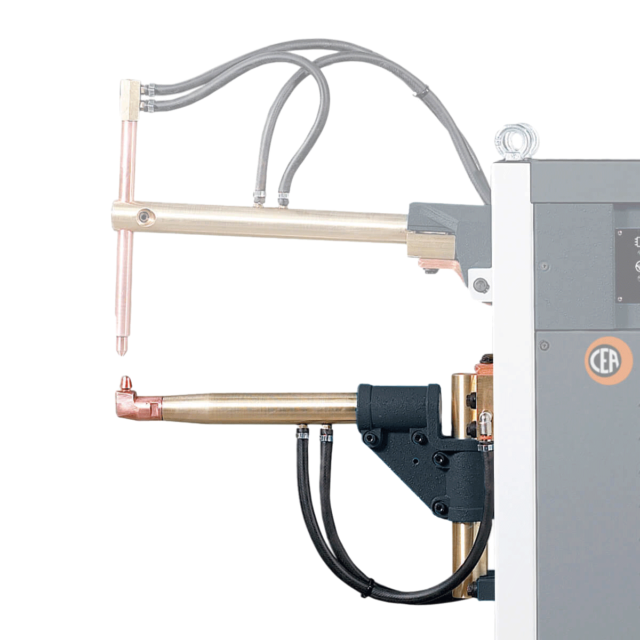

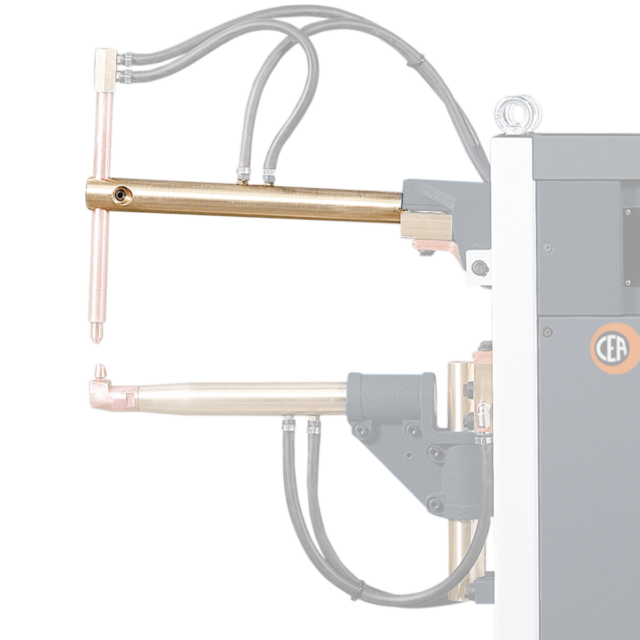

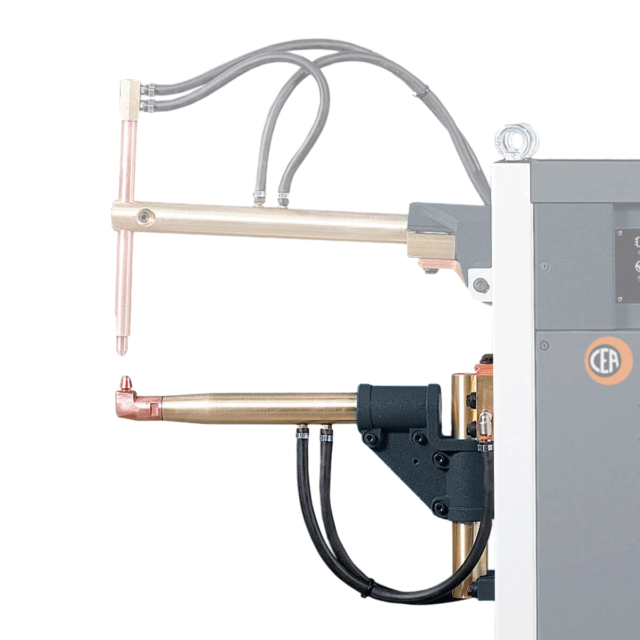

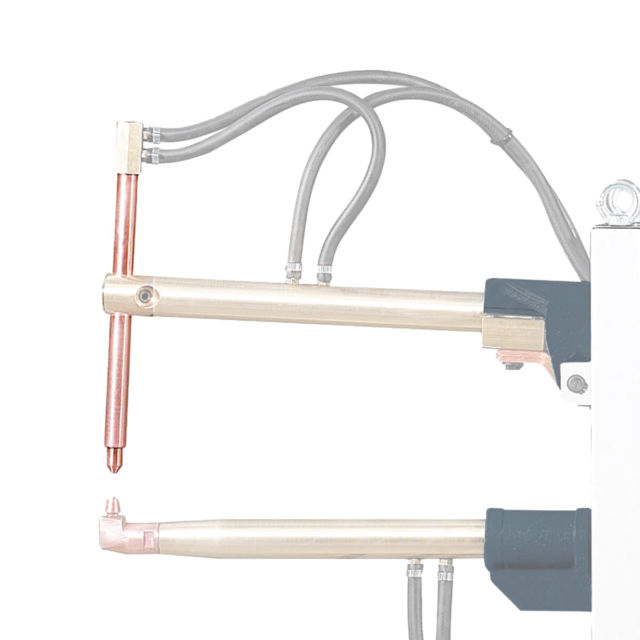

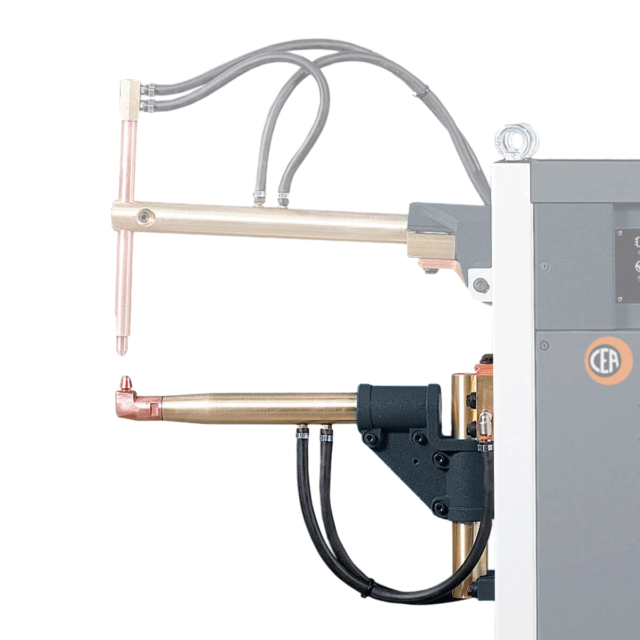

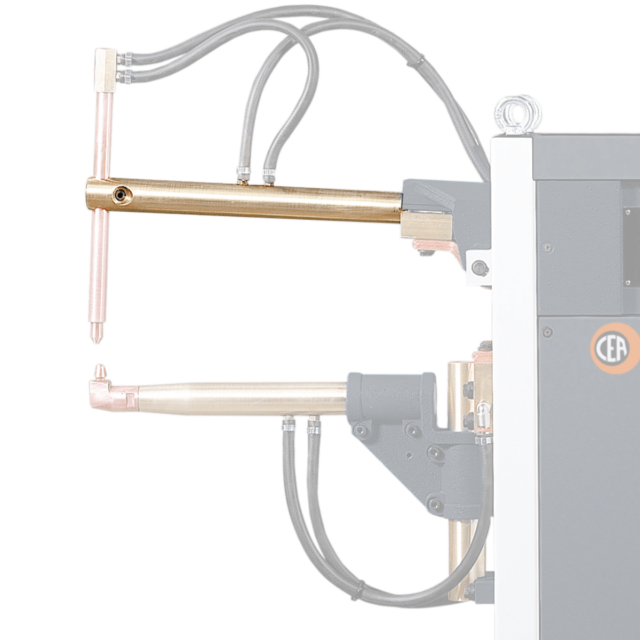

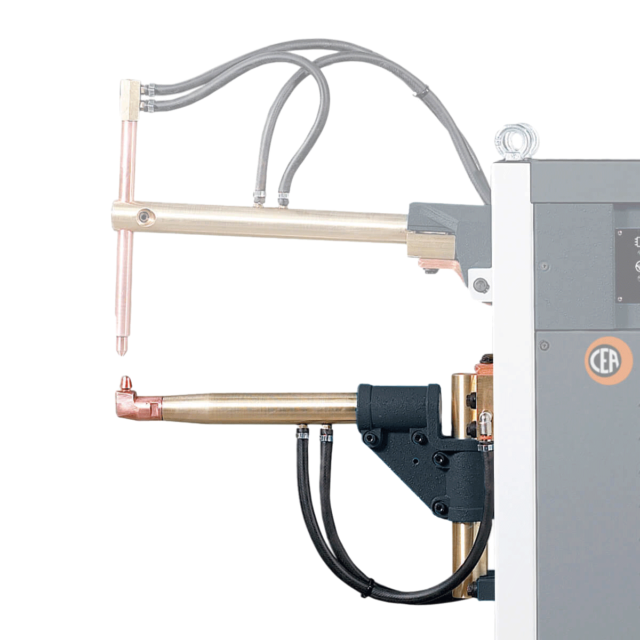

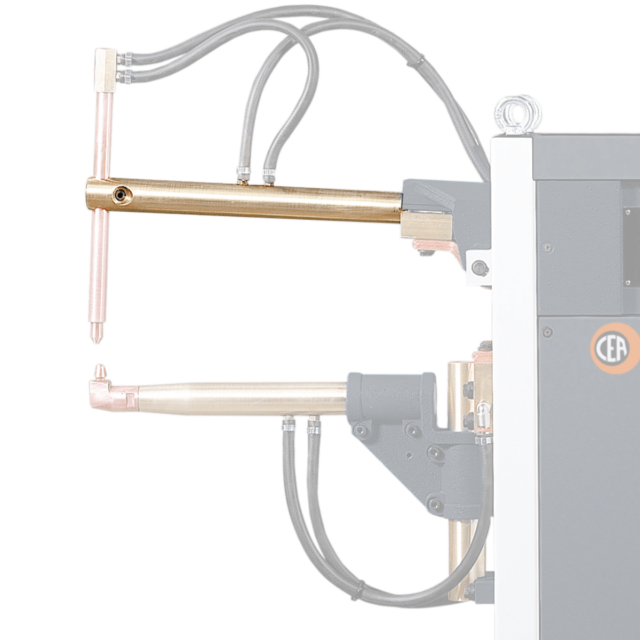

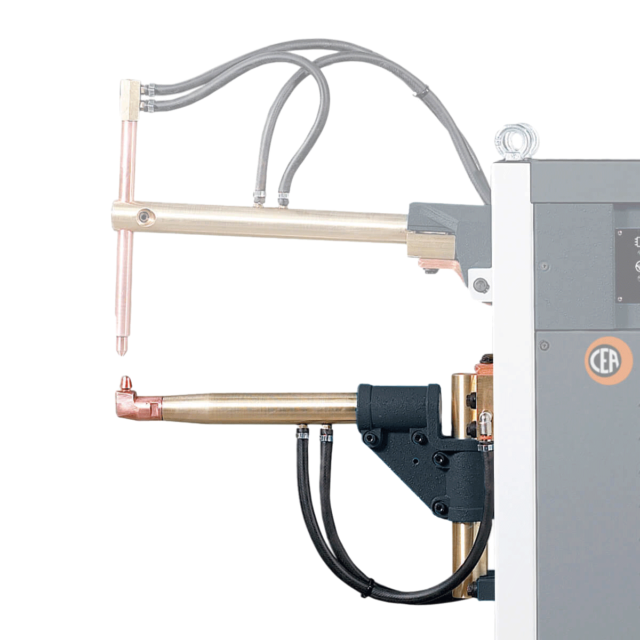

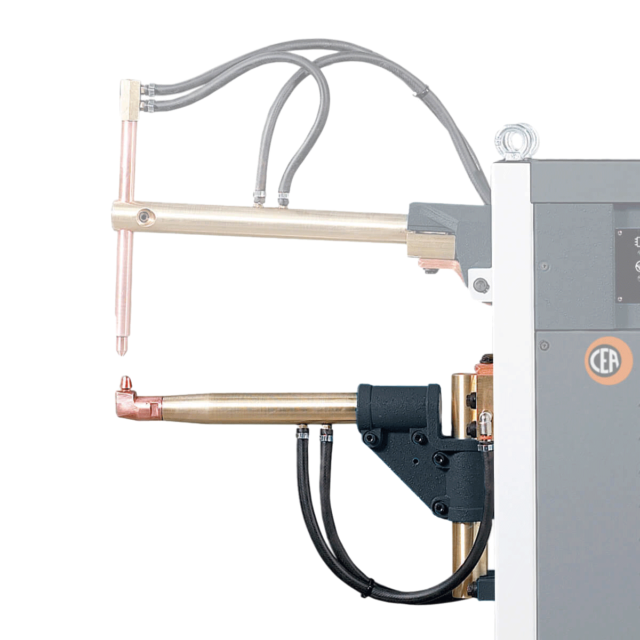

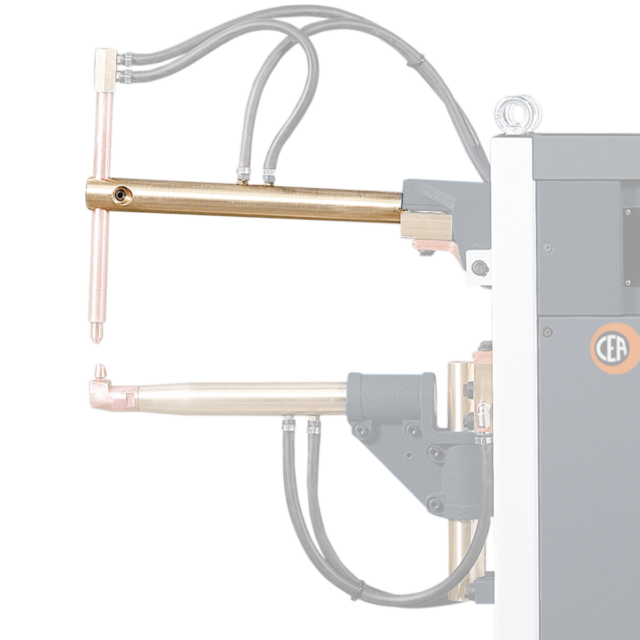

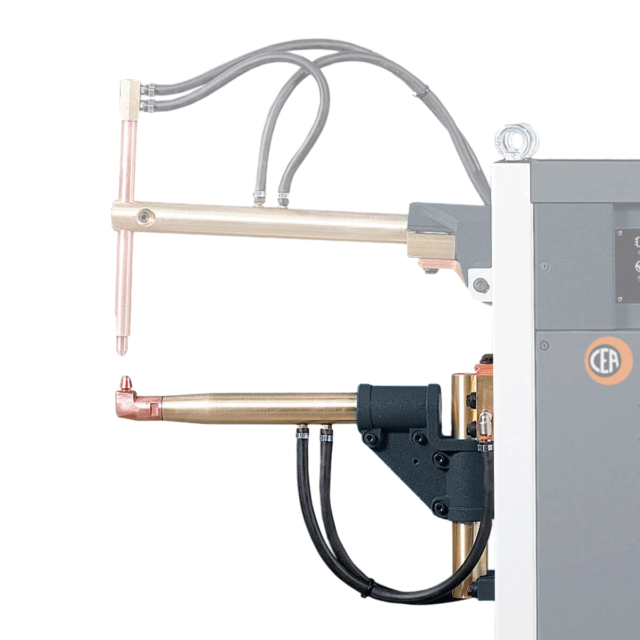

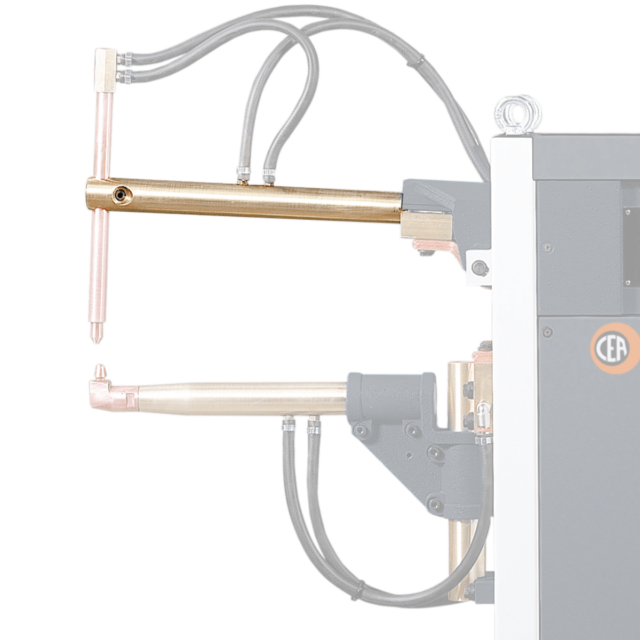

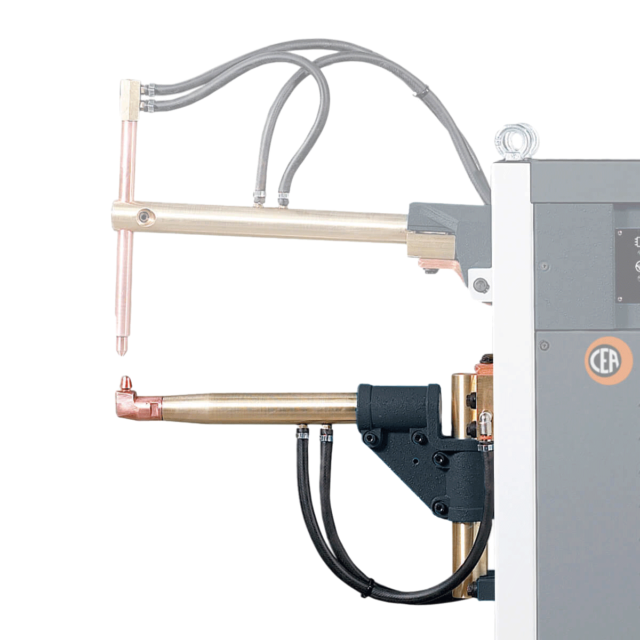

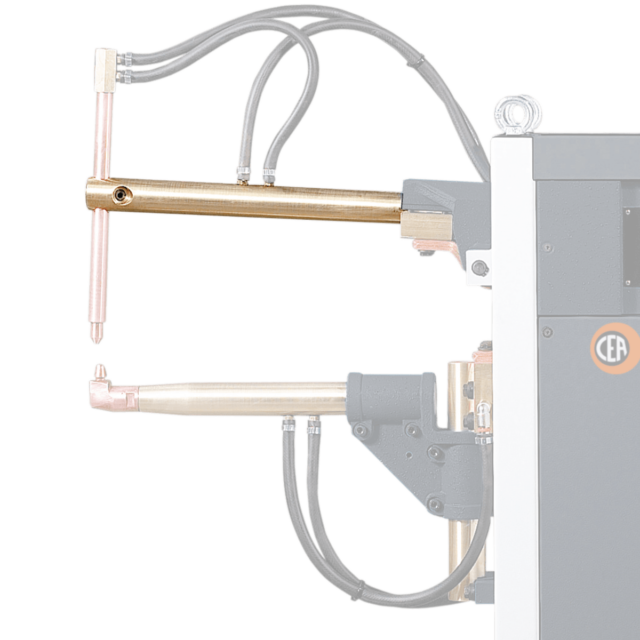

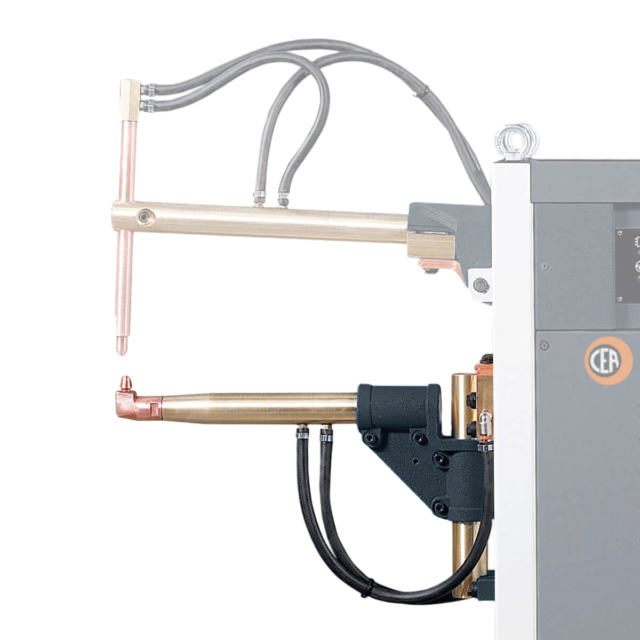

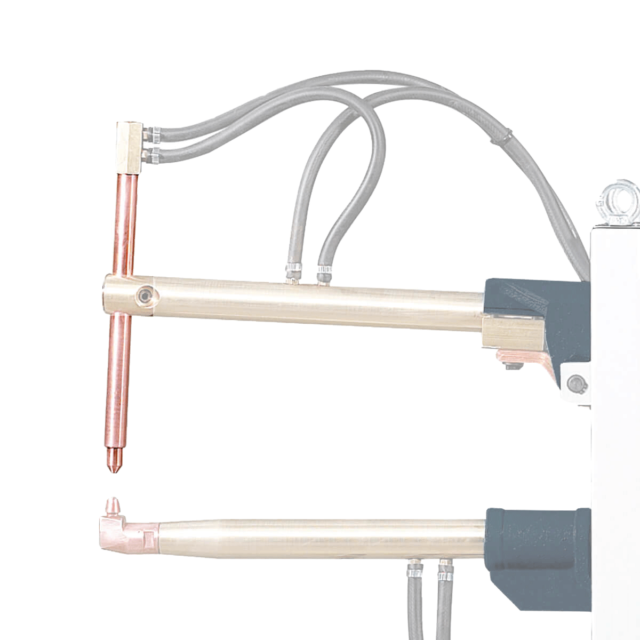

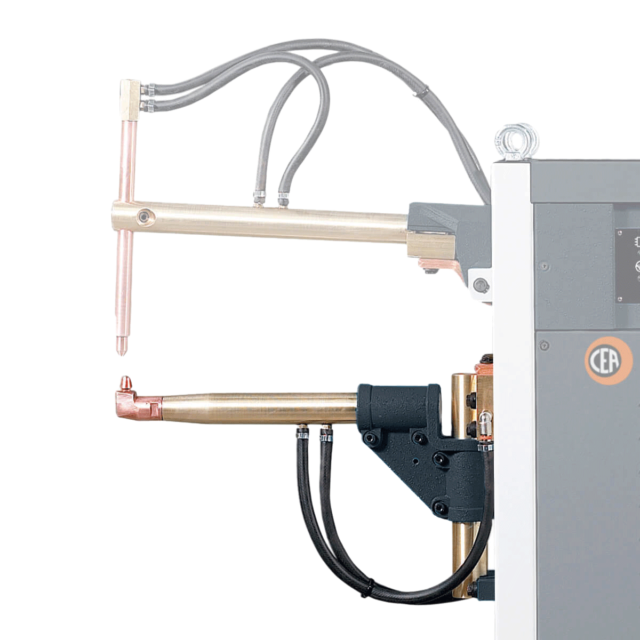

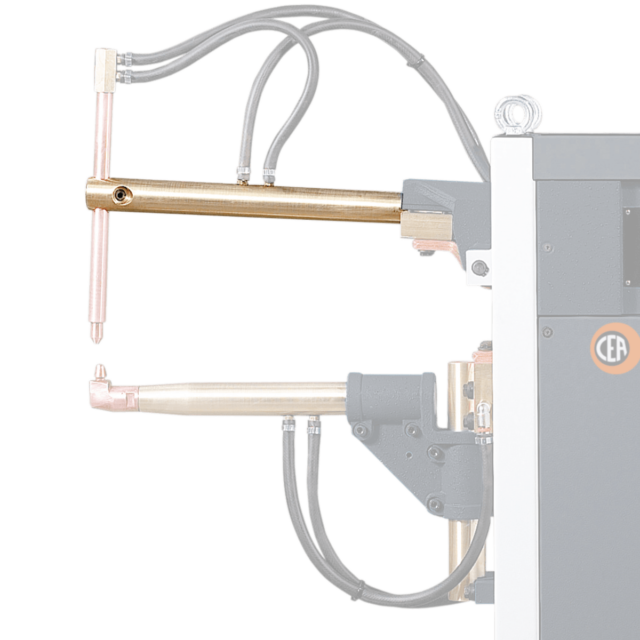

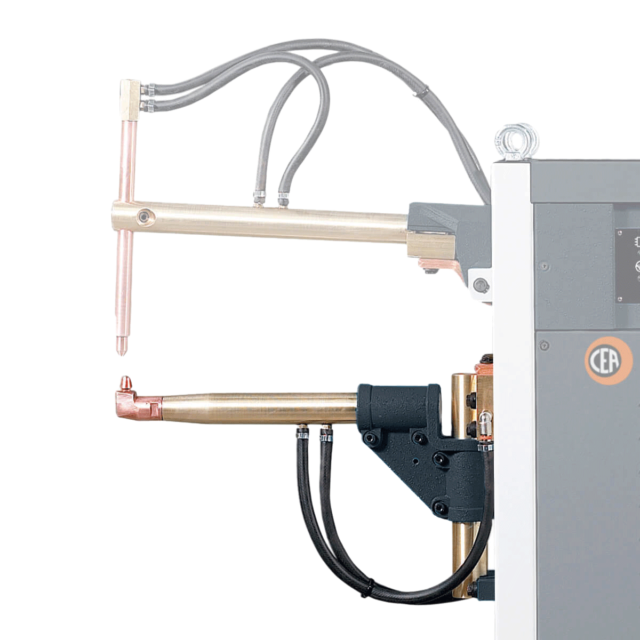

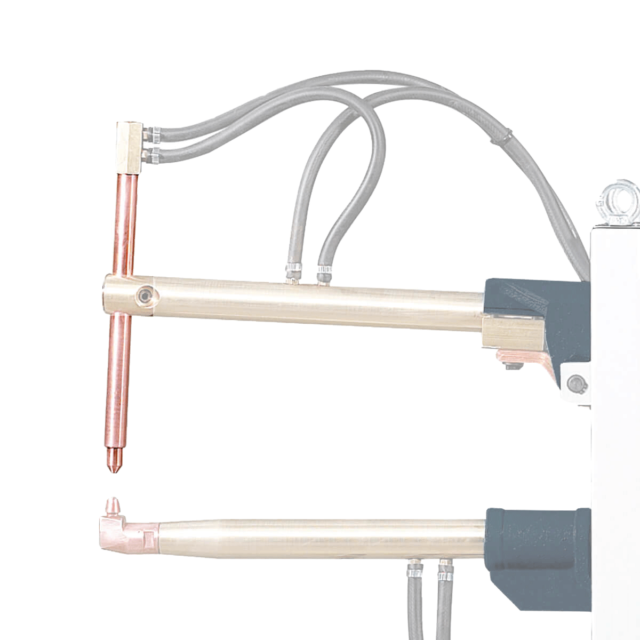

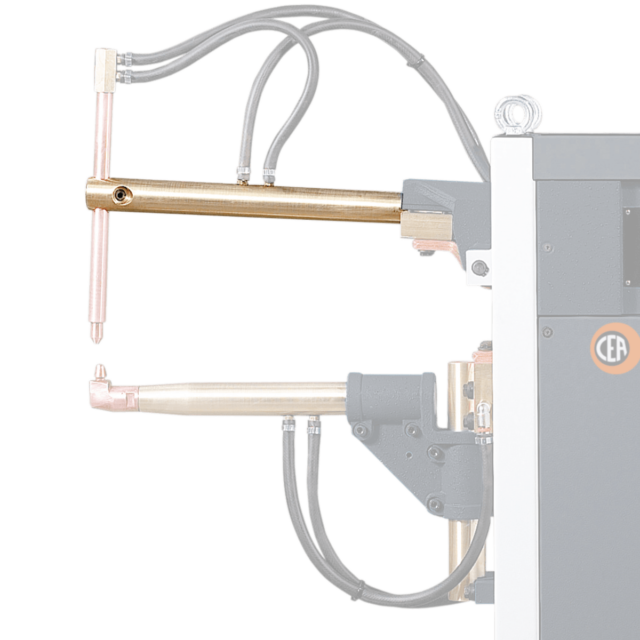

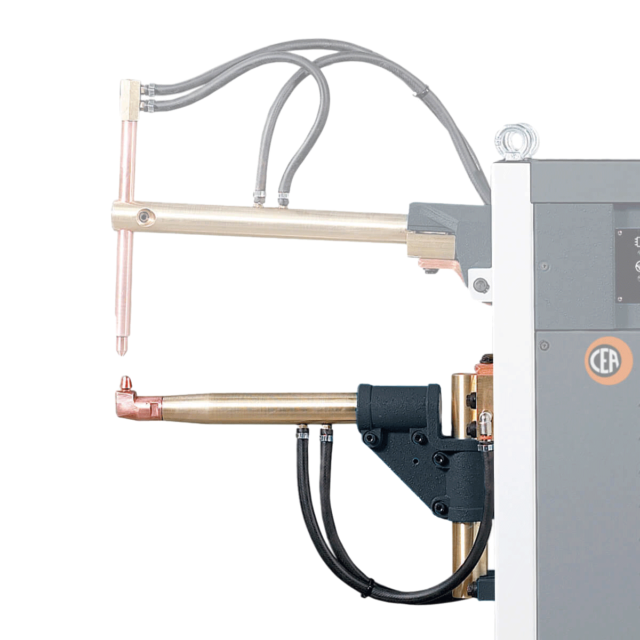

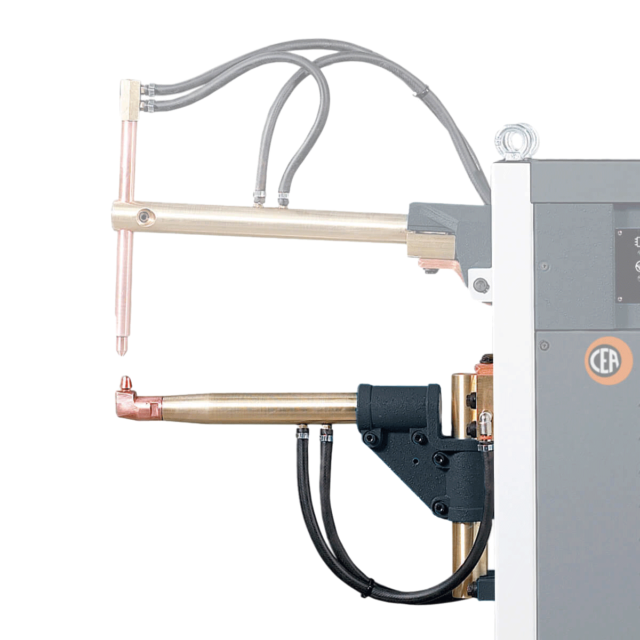

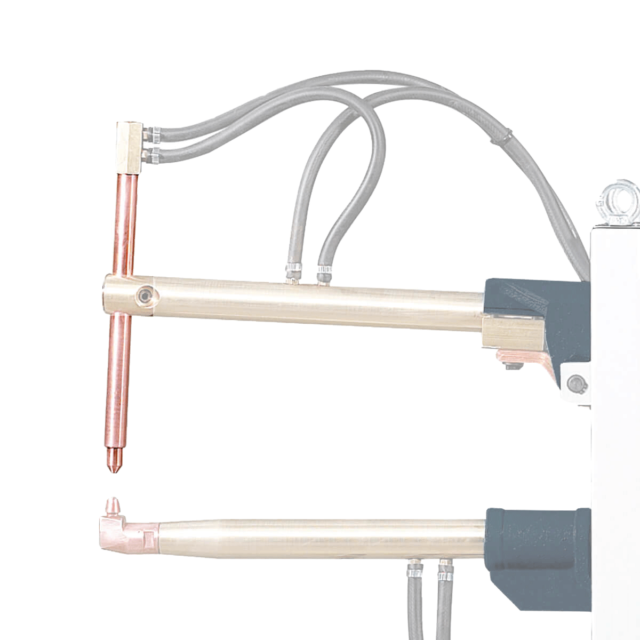

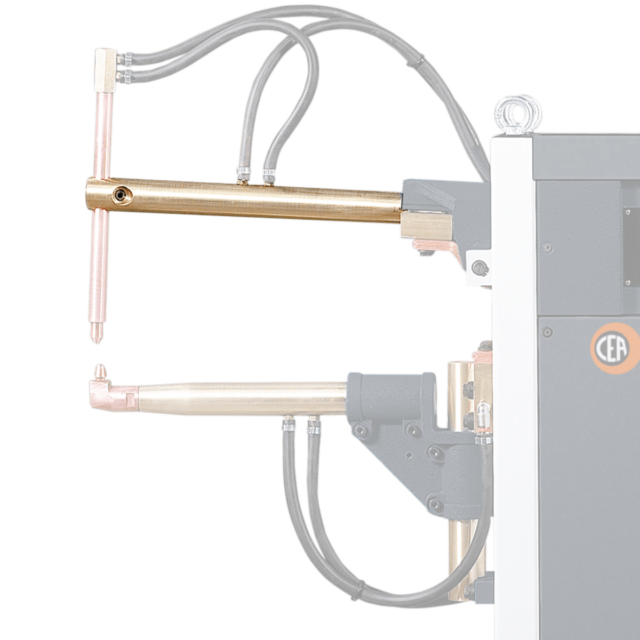

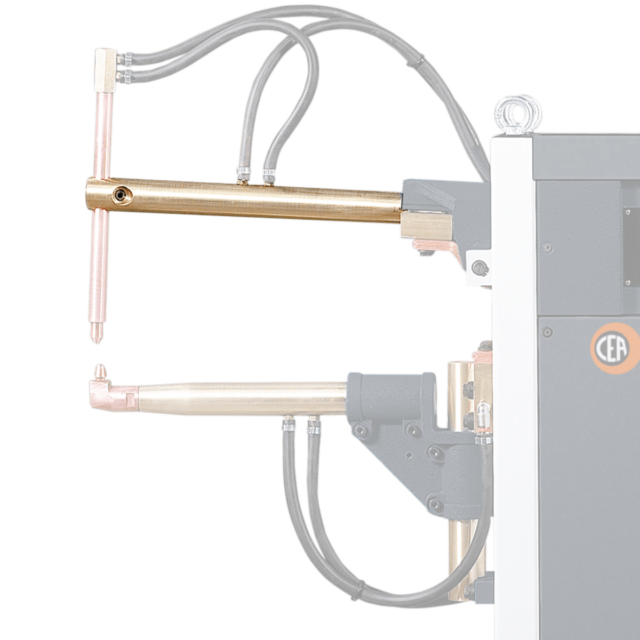

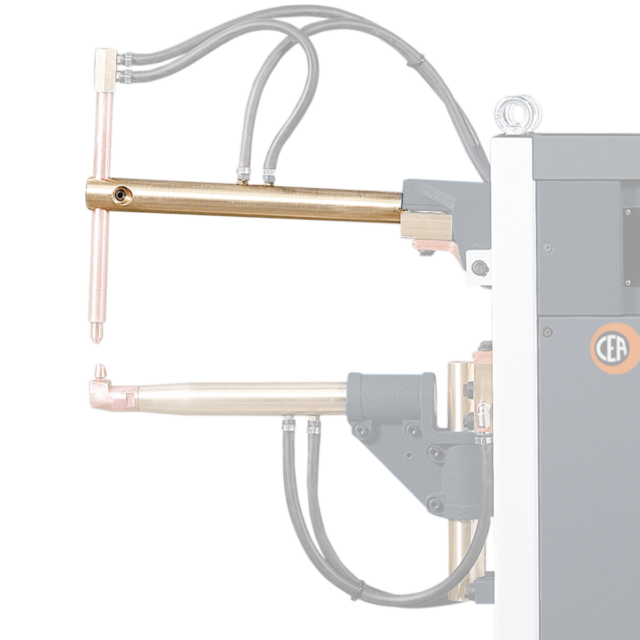

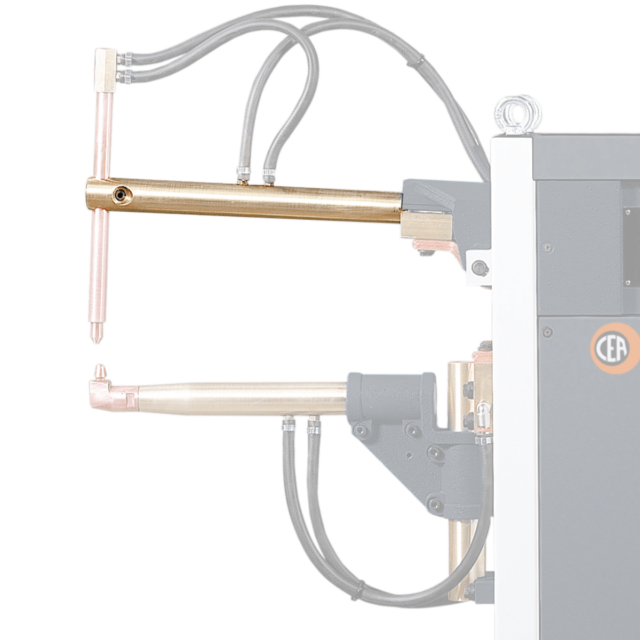

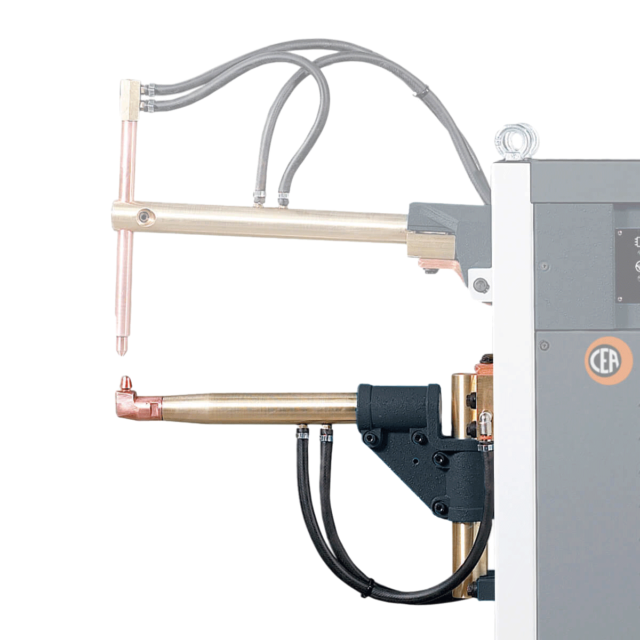

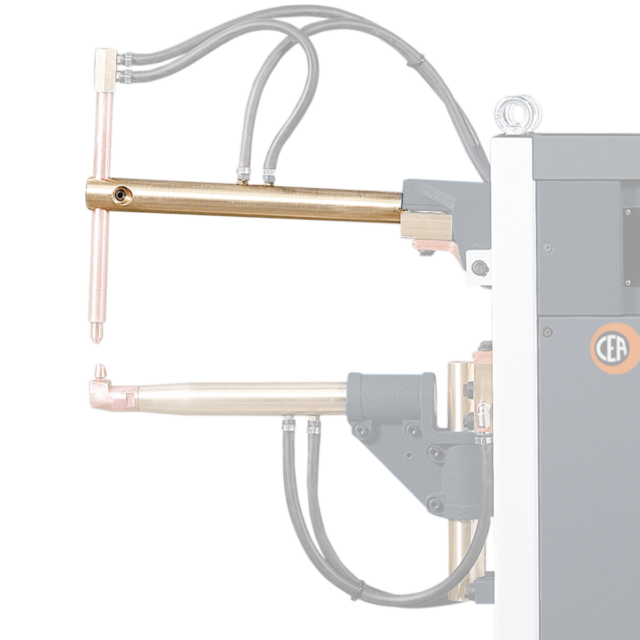

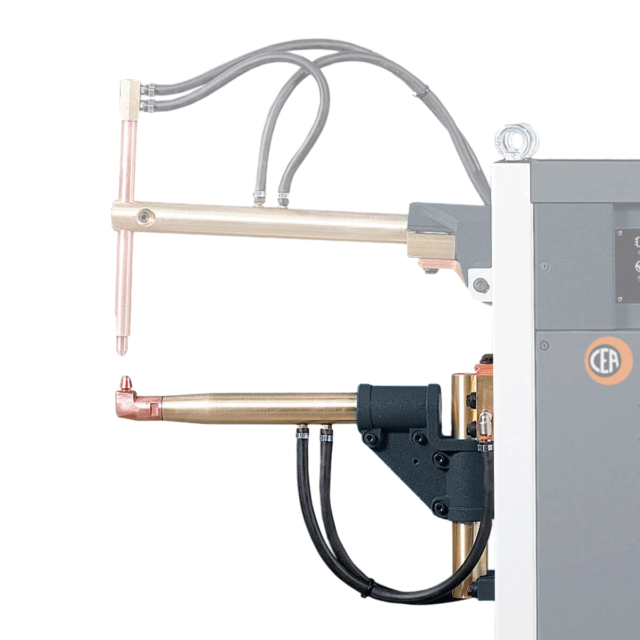

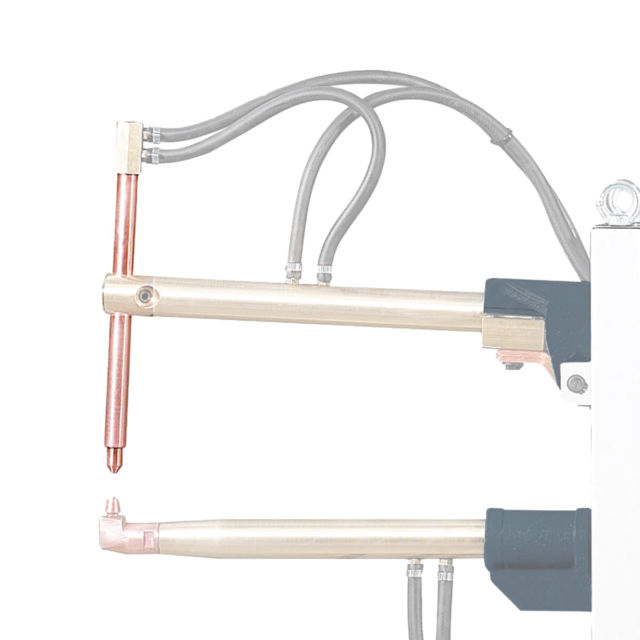

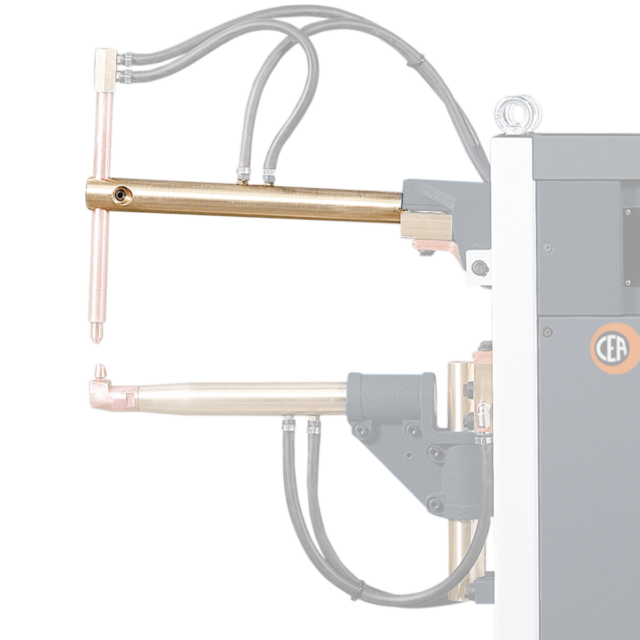

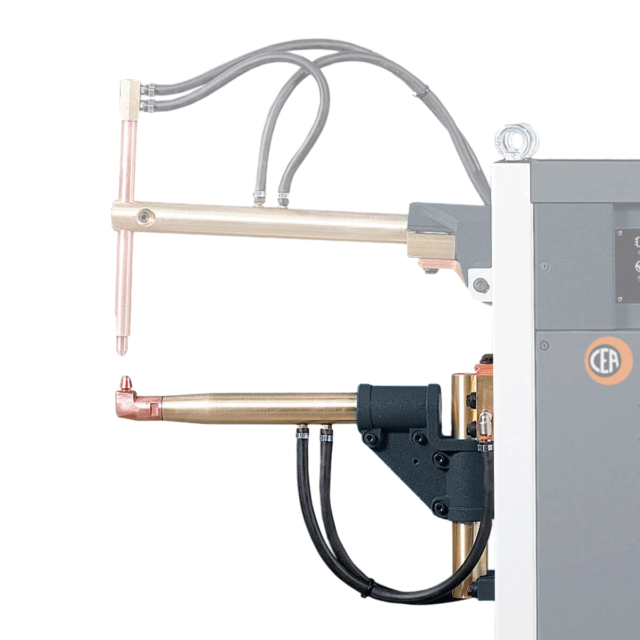

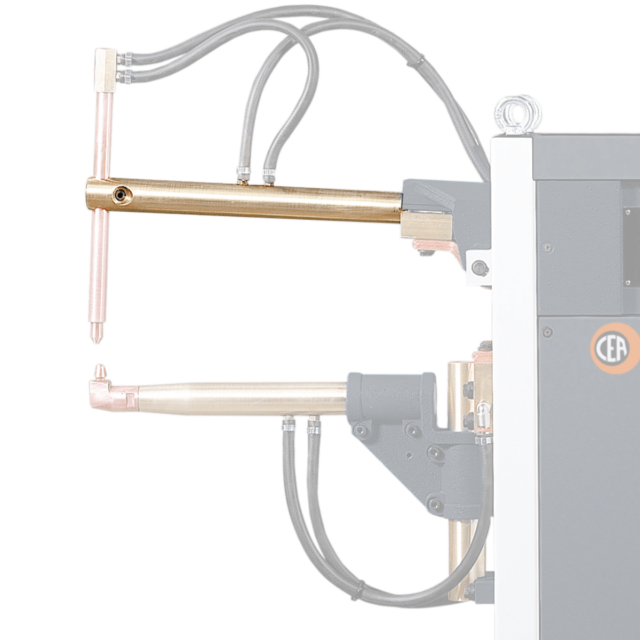

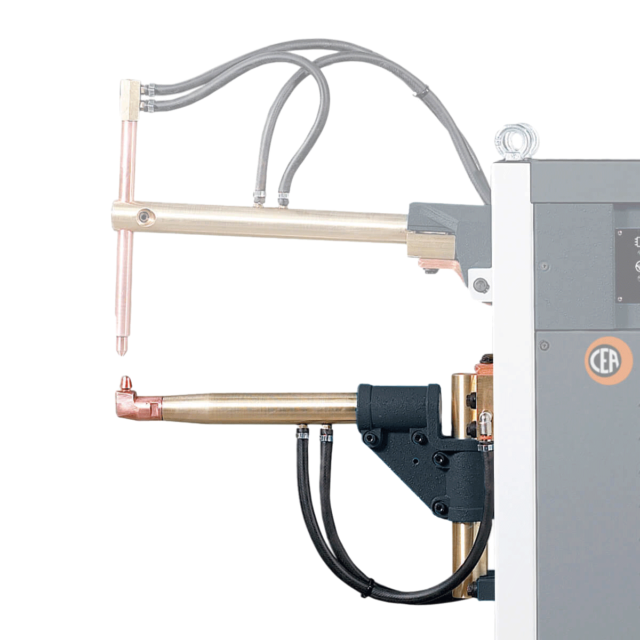

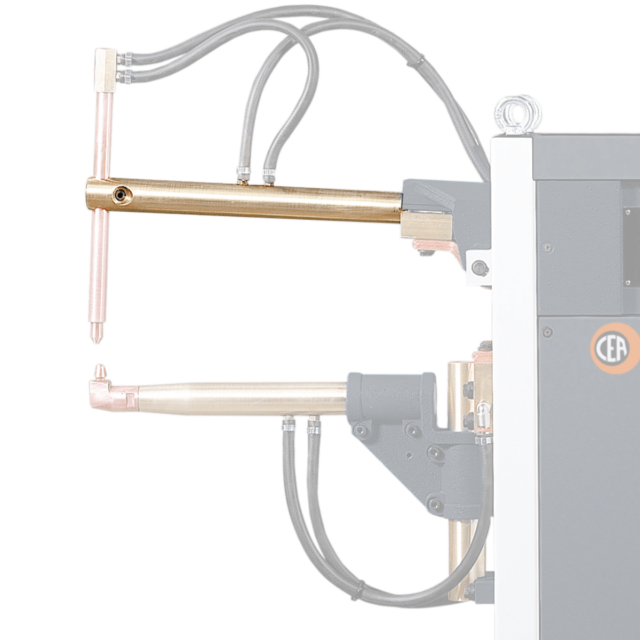

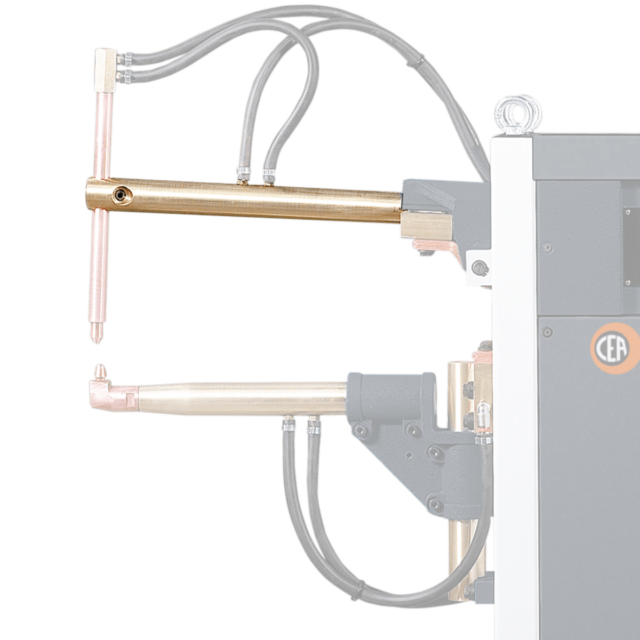

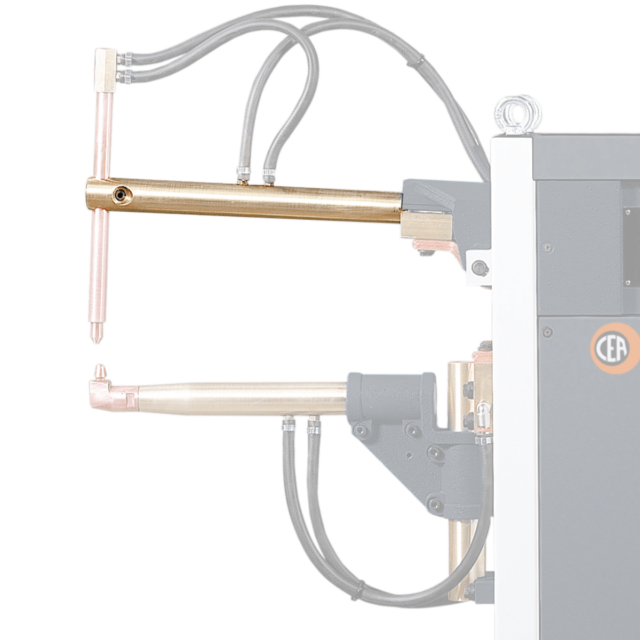

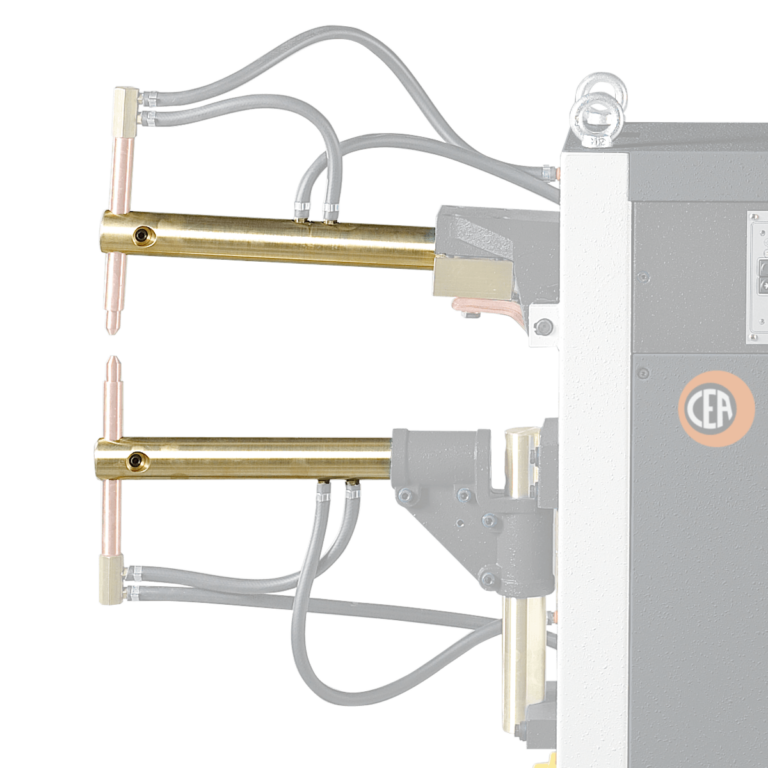

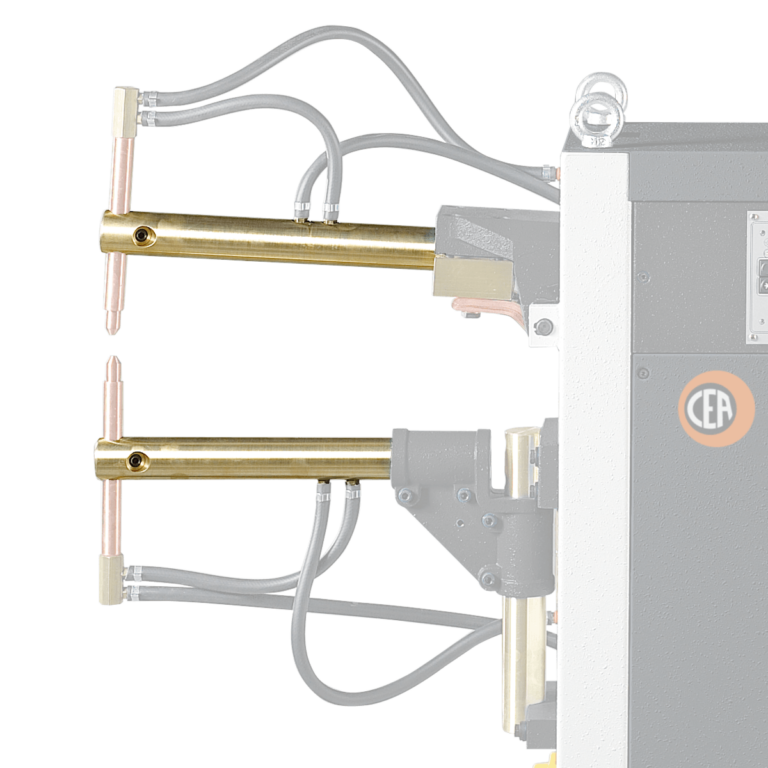

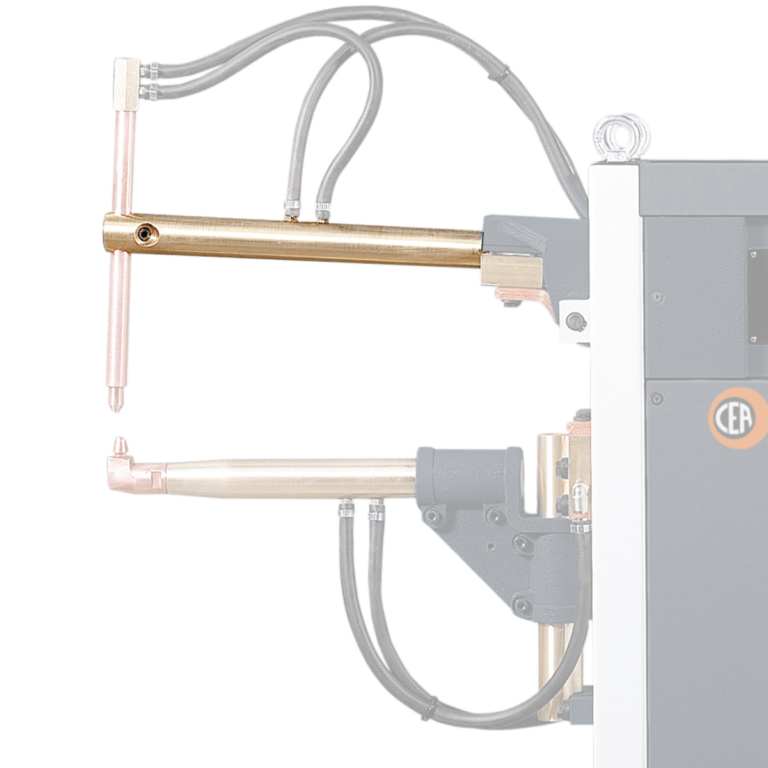

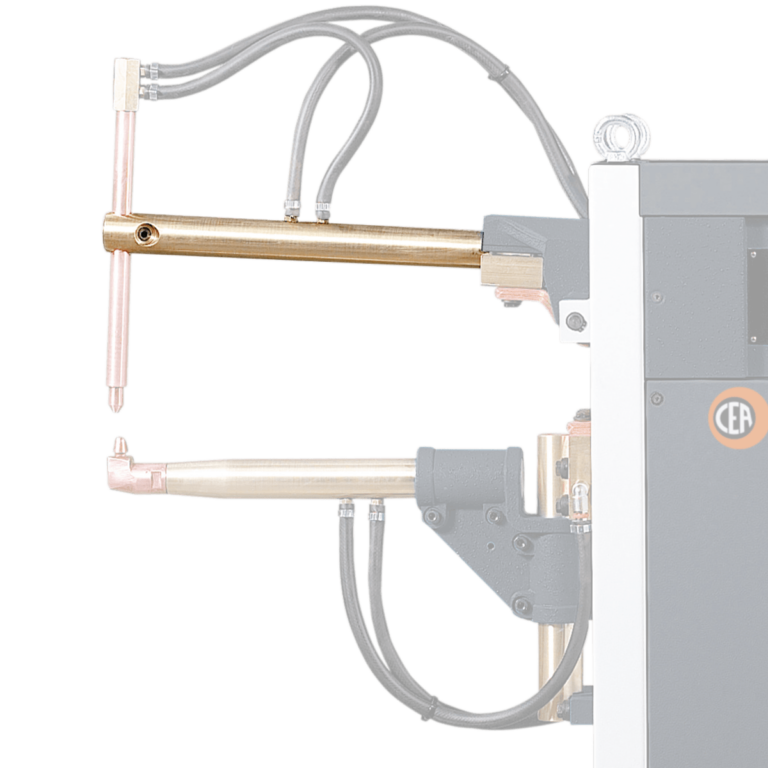

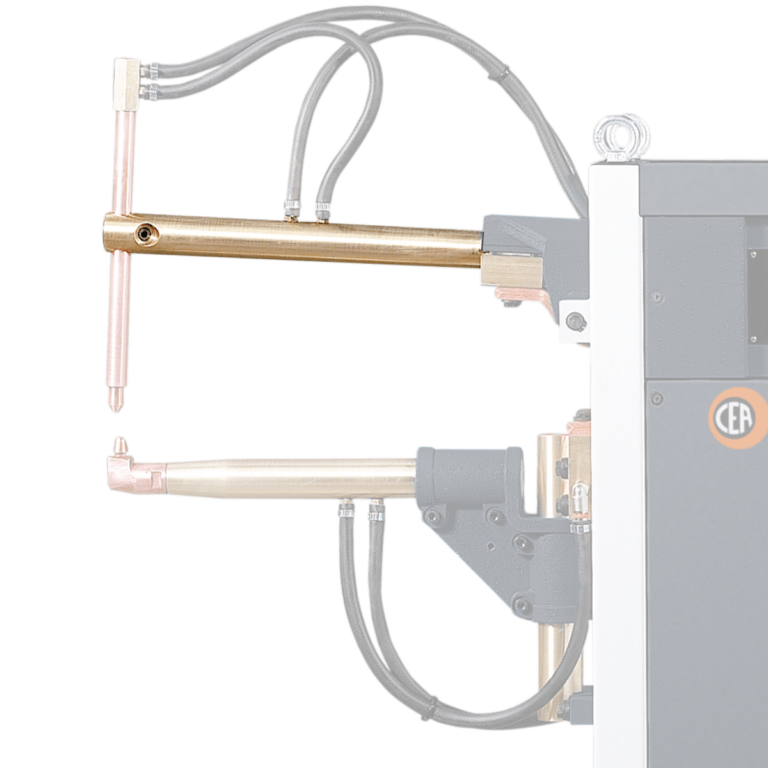

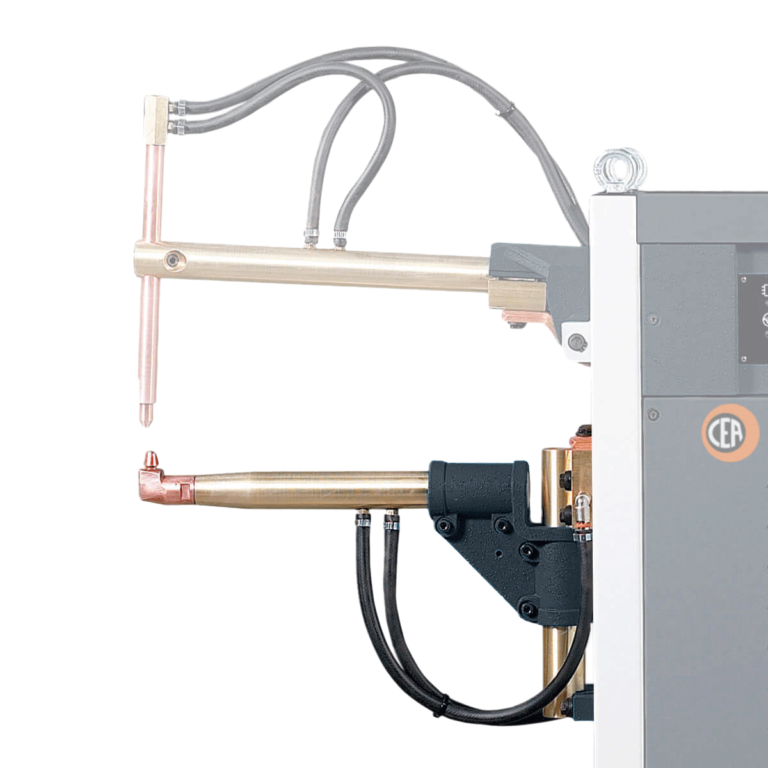

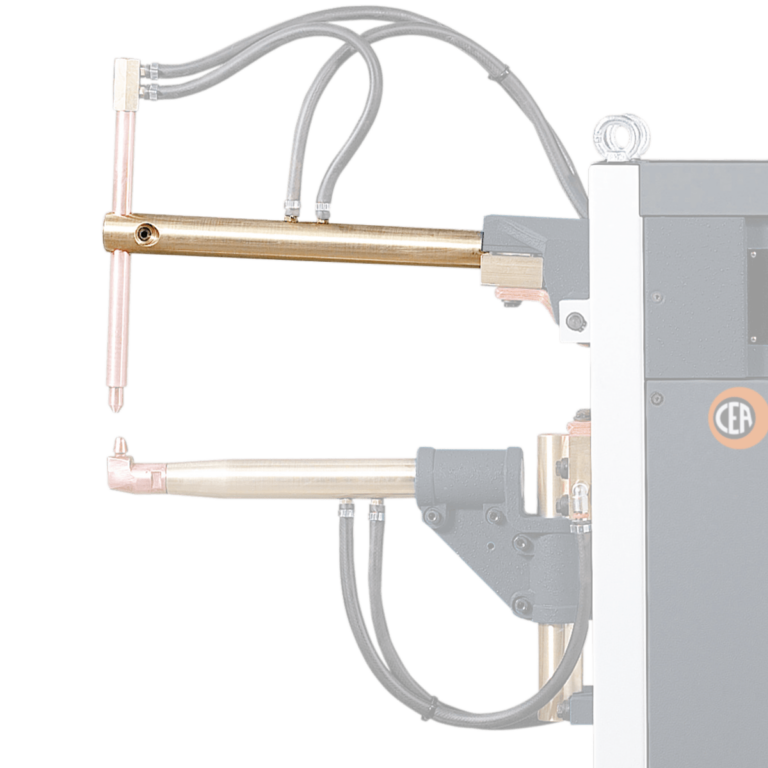

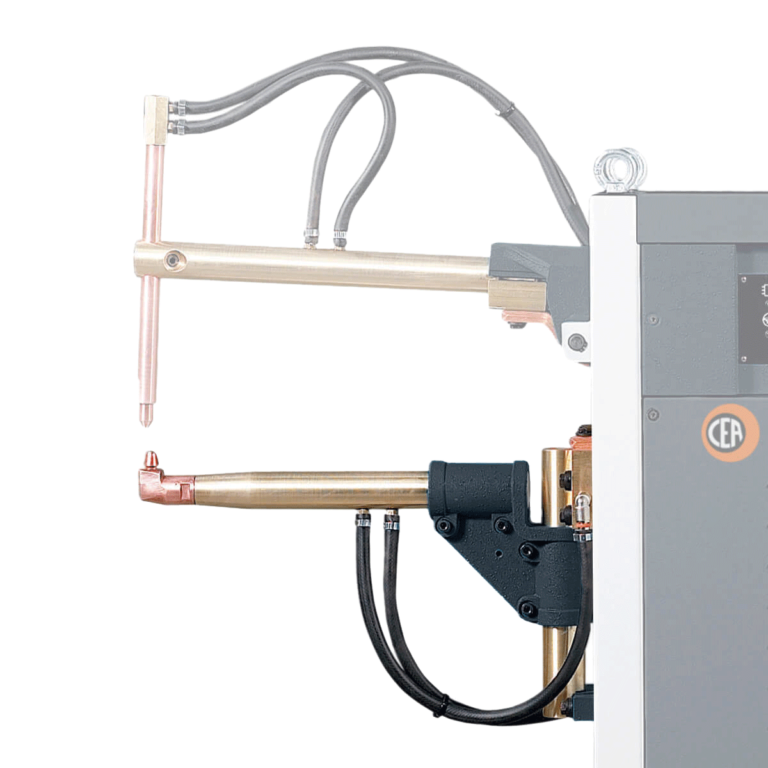

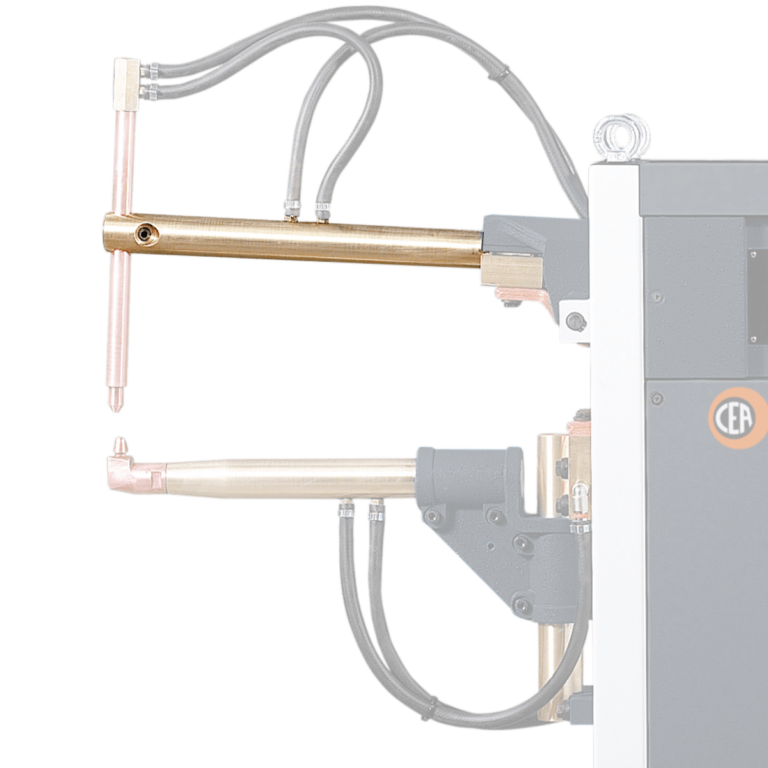

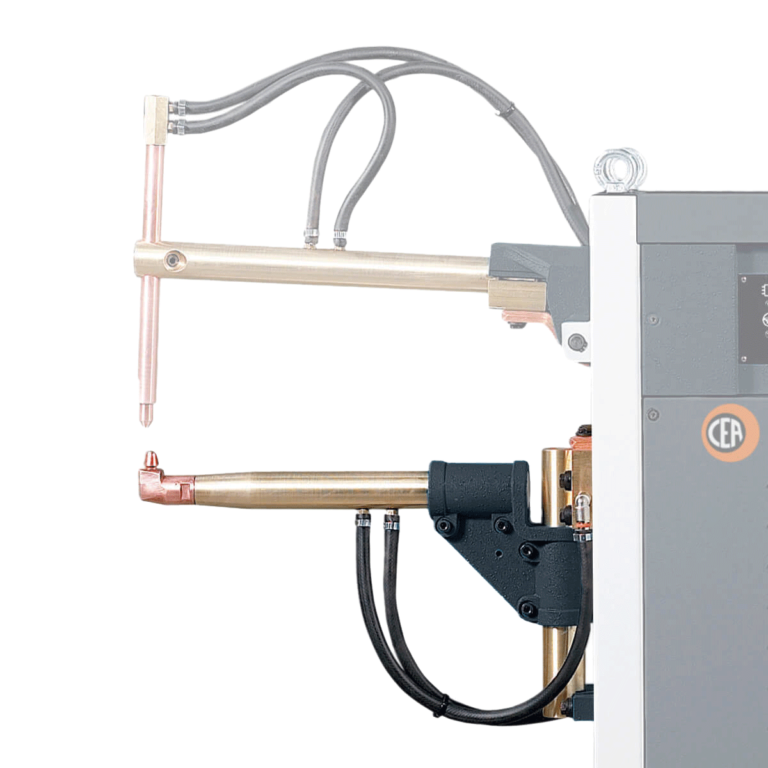

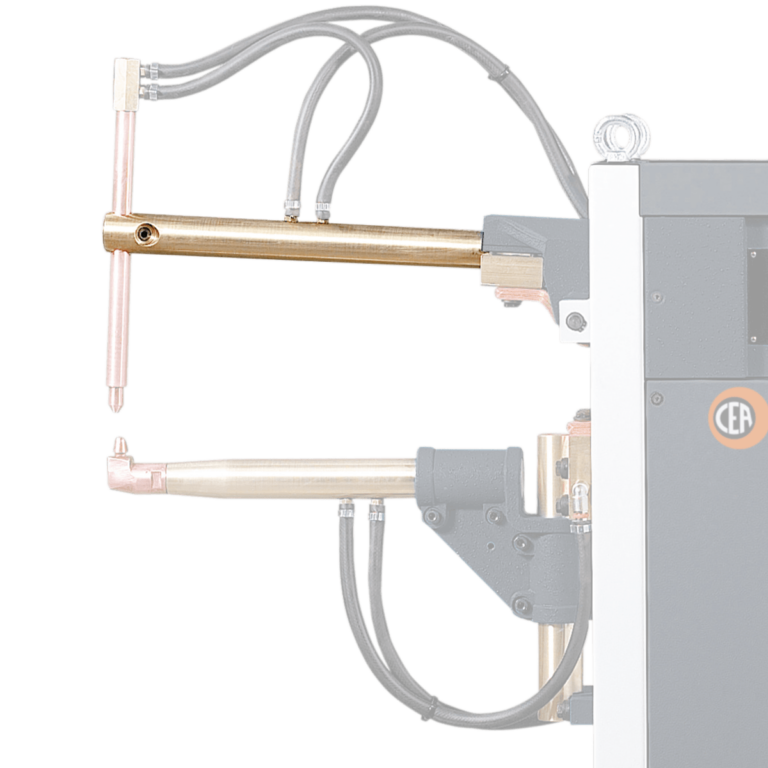

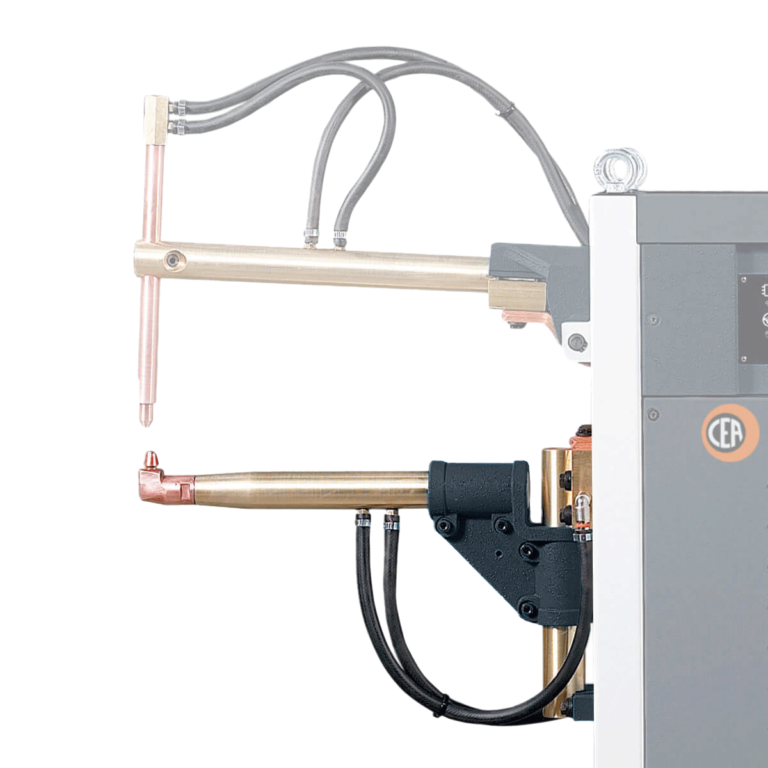

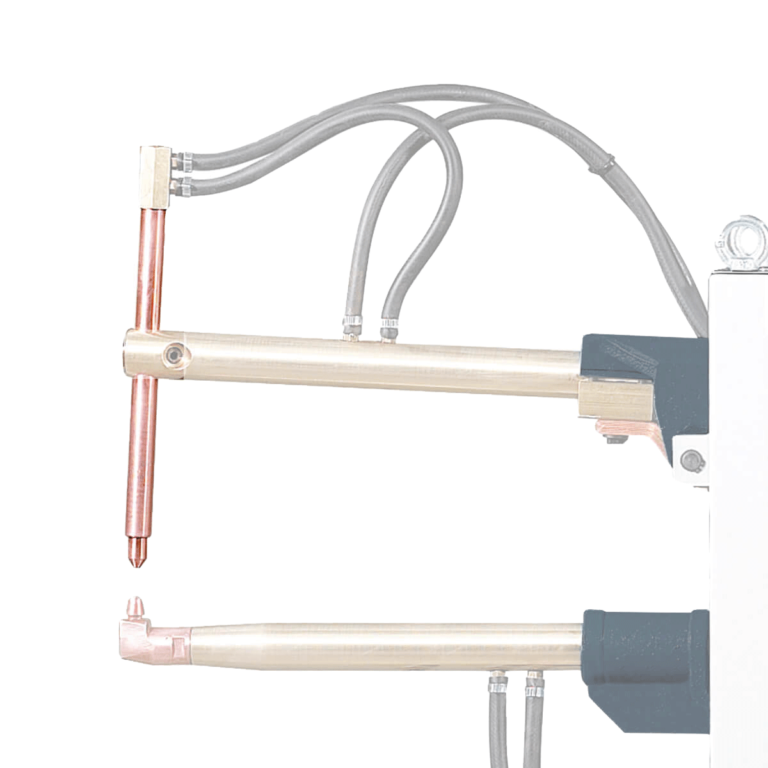

Set of arms 455 mm cooled Ø 40 mm

"*" indicates required fields

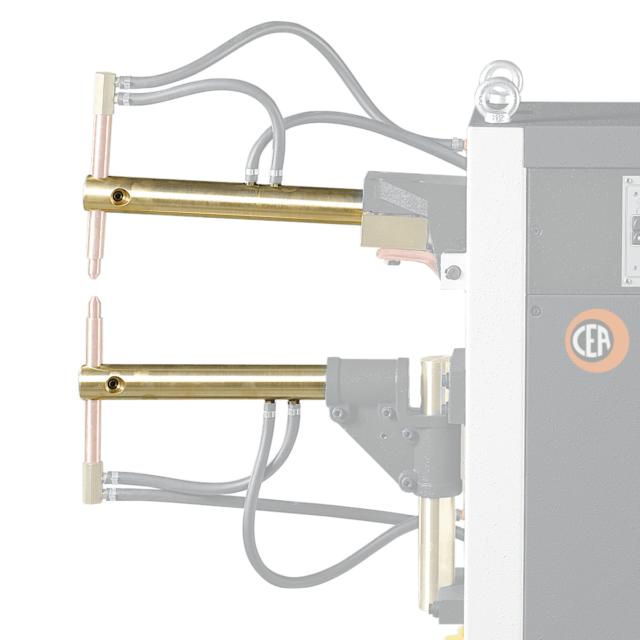

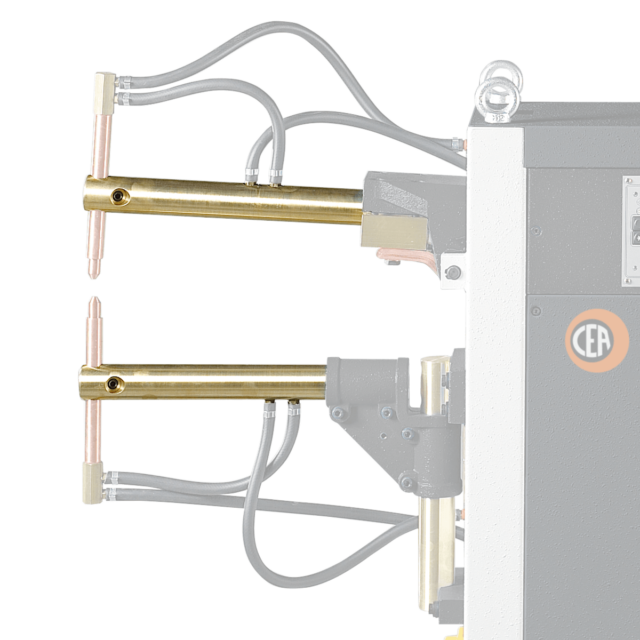

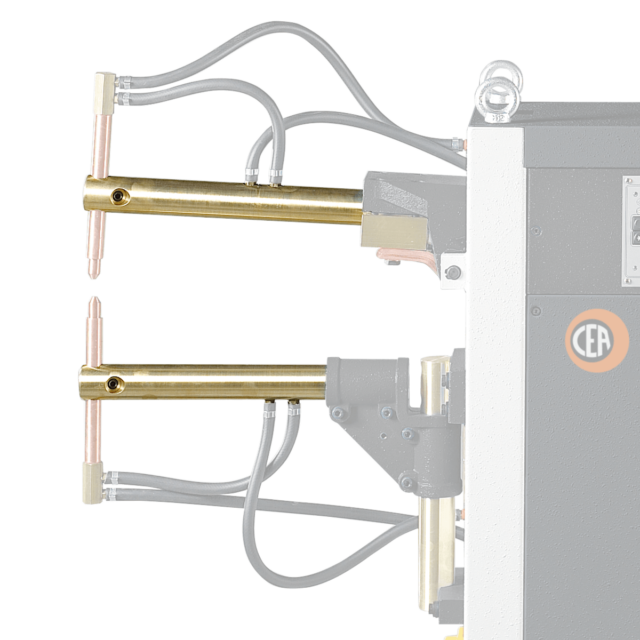

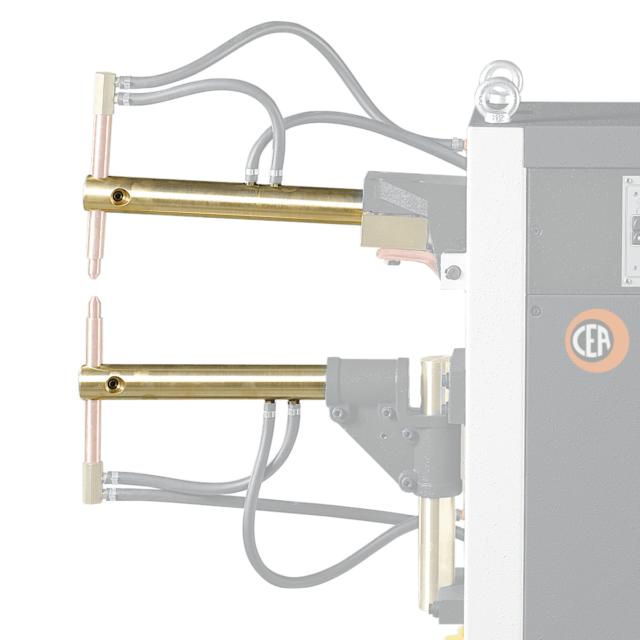

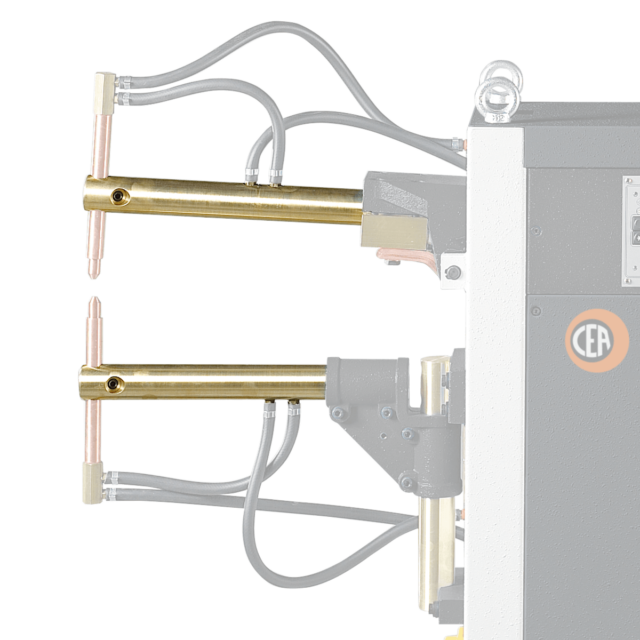

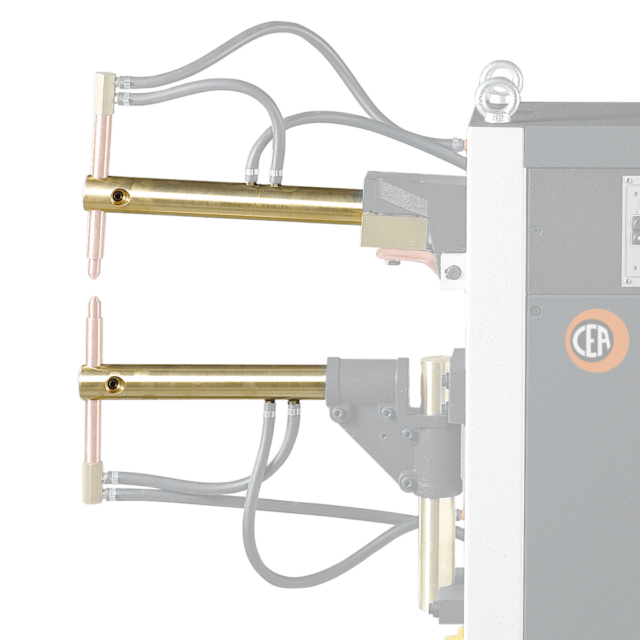

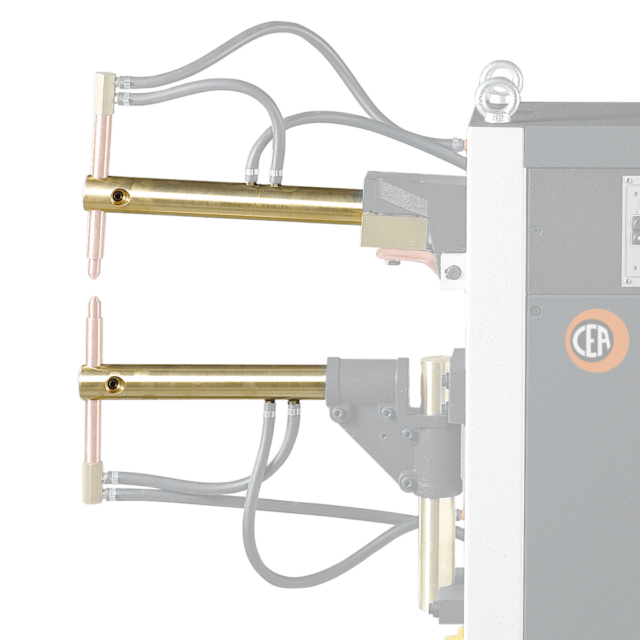

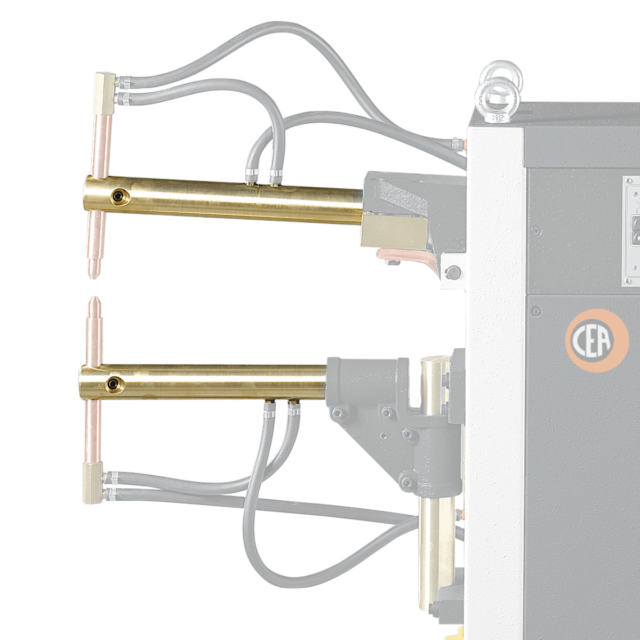

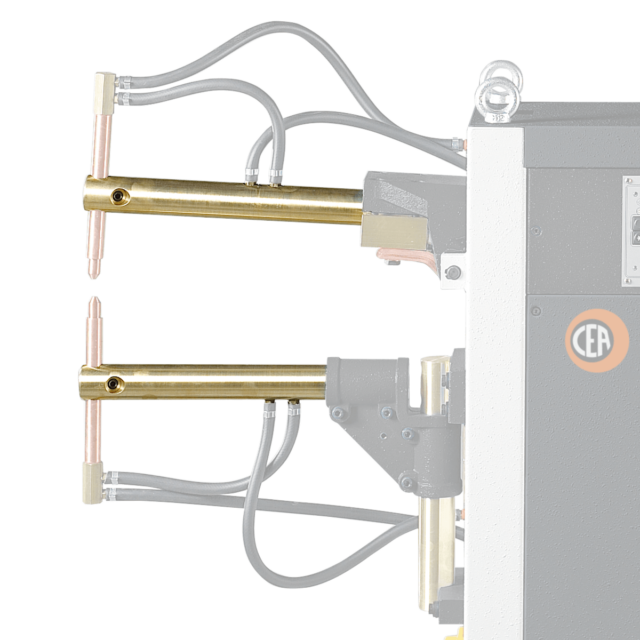

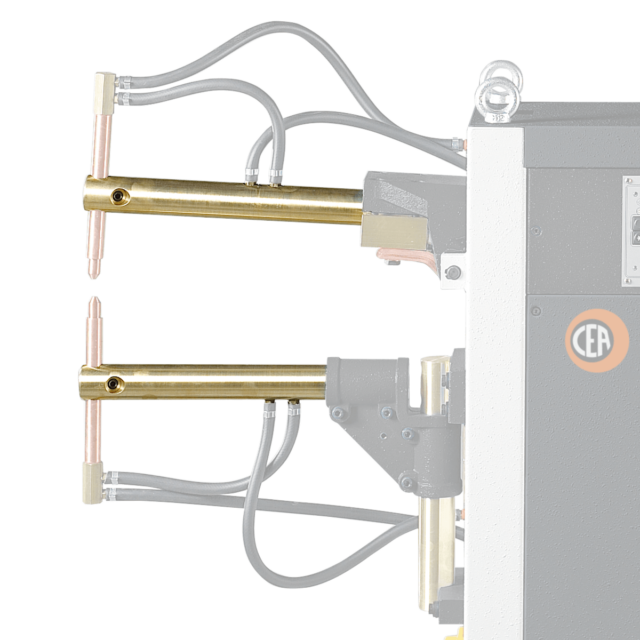

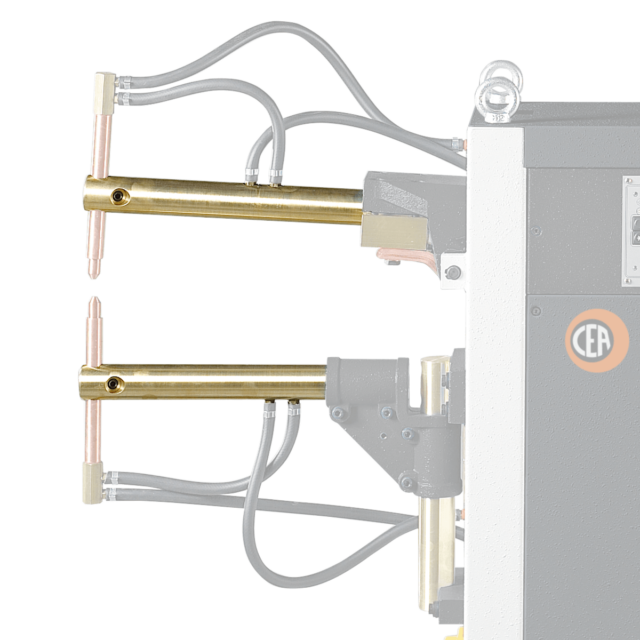

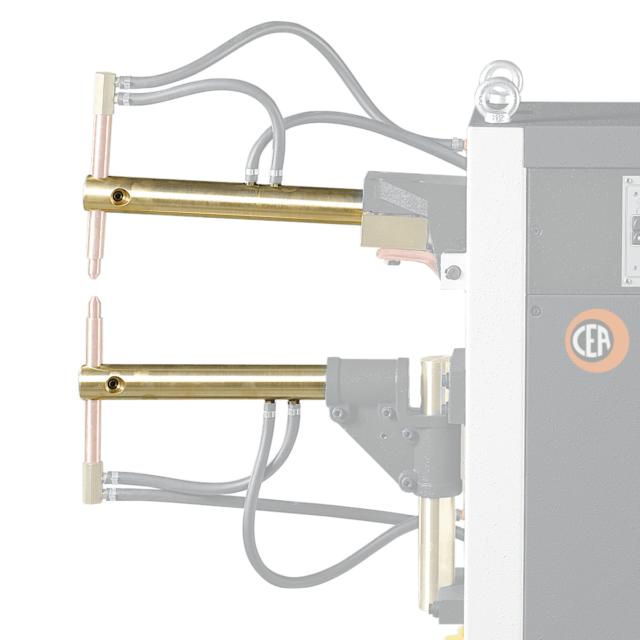

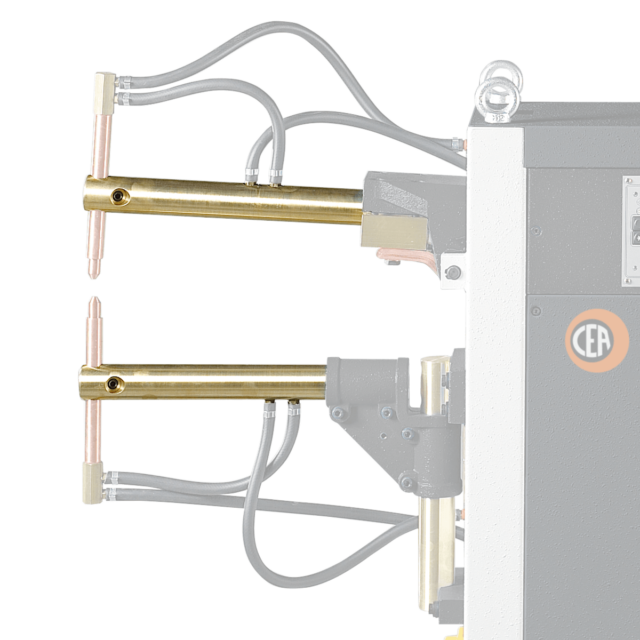

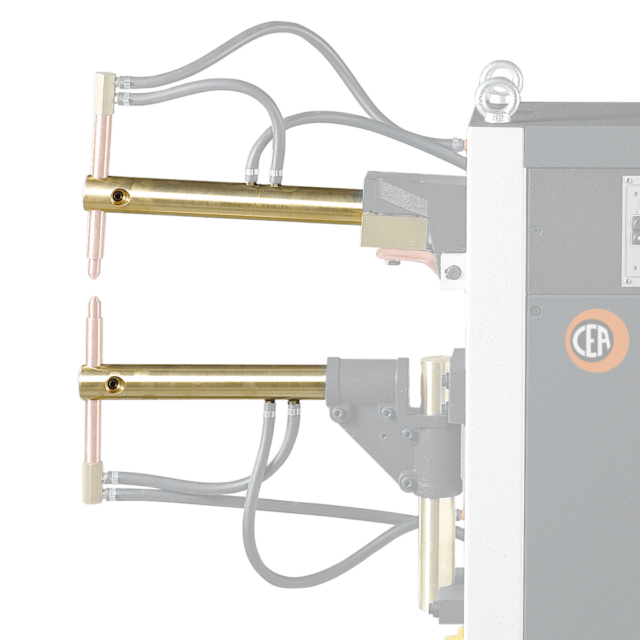

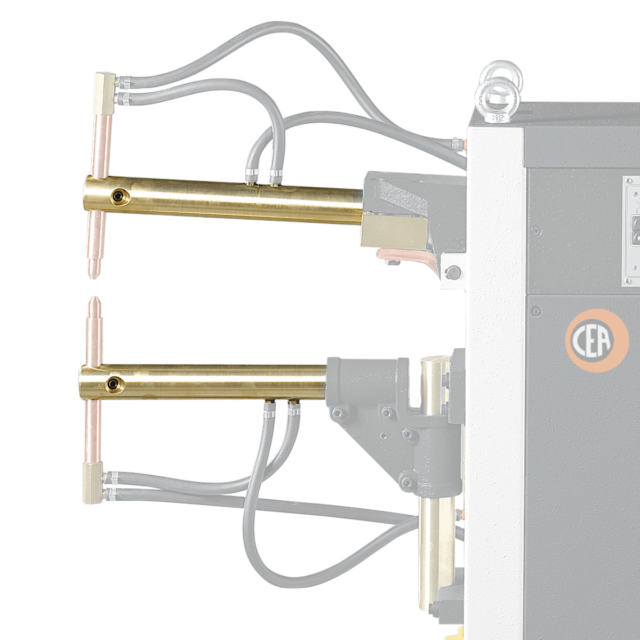

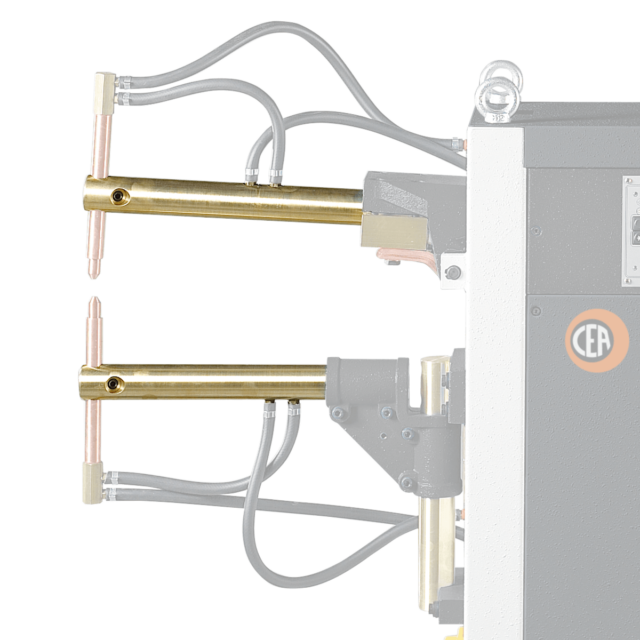

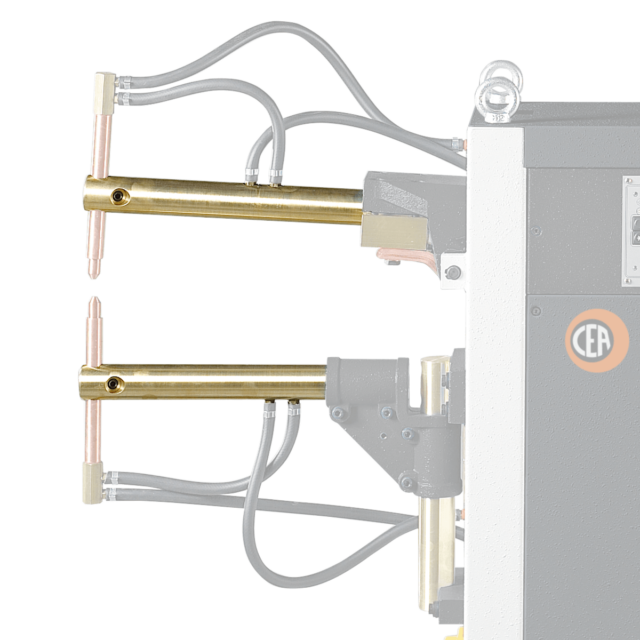

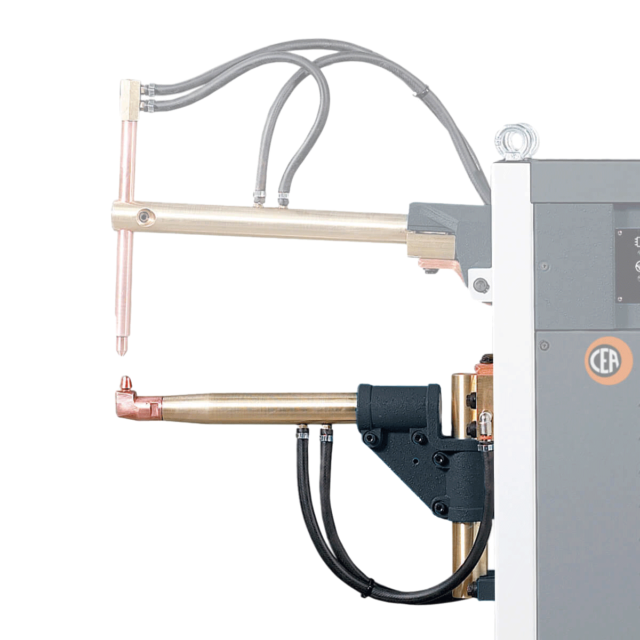

K-KP series resistance spot welders, versatile, robust and easy-to-use, ensure best welding results on any weldable metal and are the most ideal solution for all spot welding applications. K-KP models are supplied either mechanical or air operated:

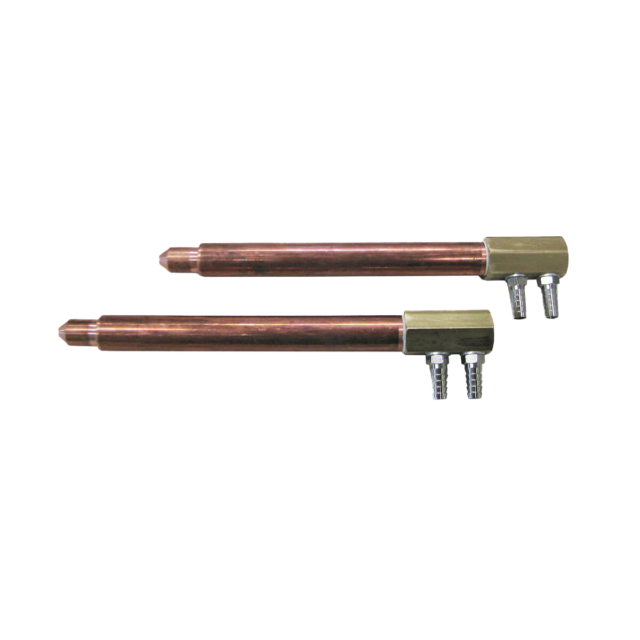

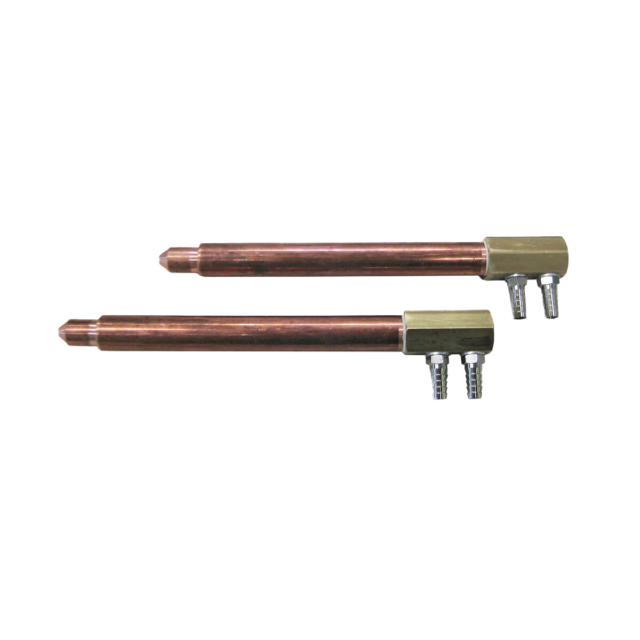

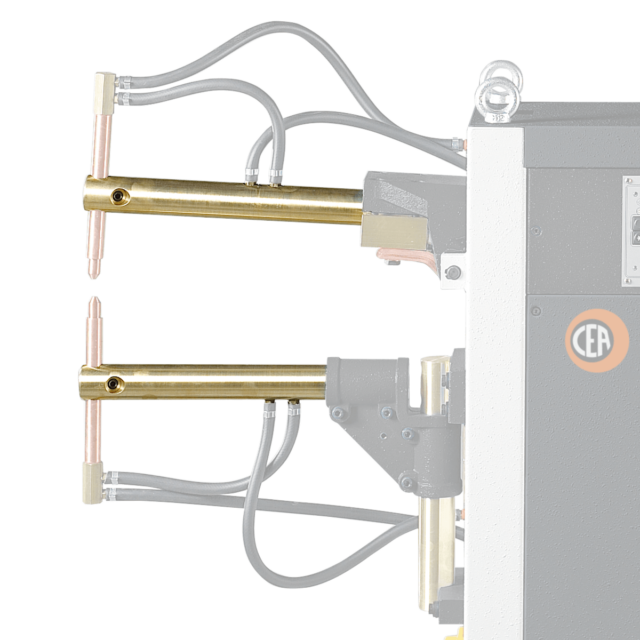

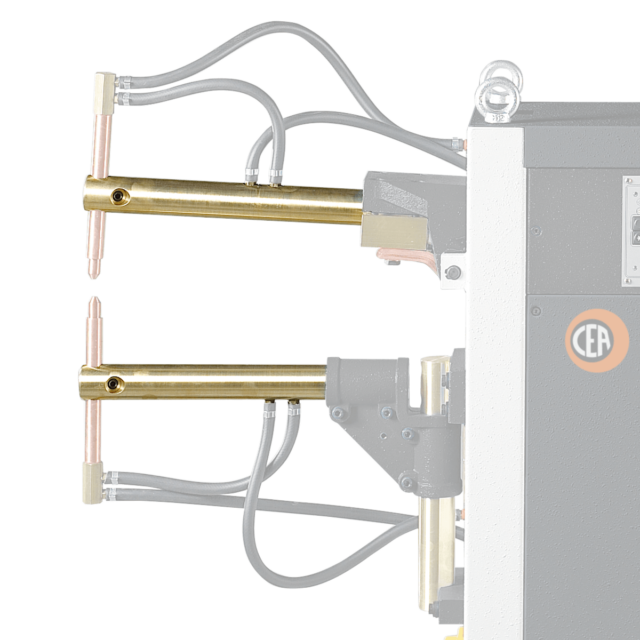

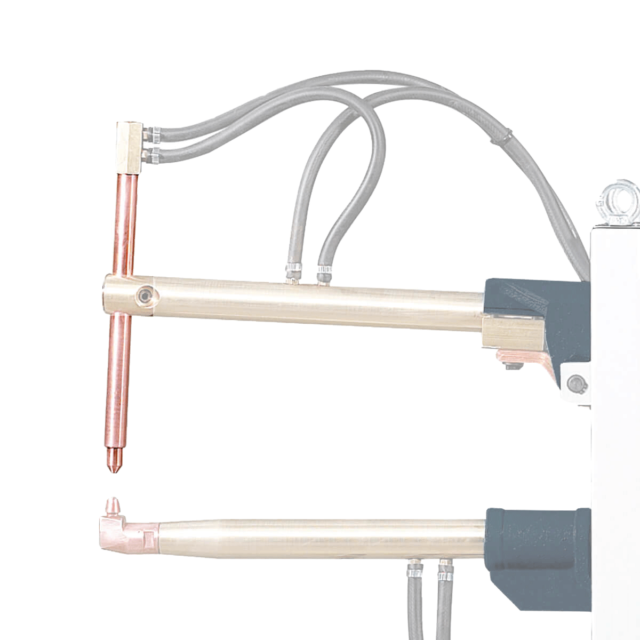

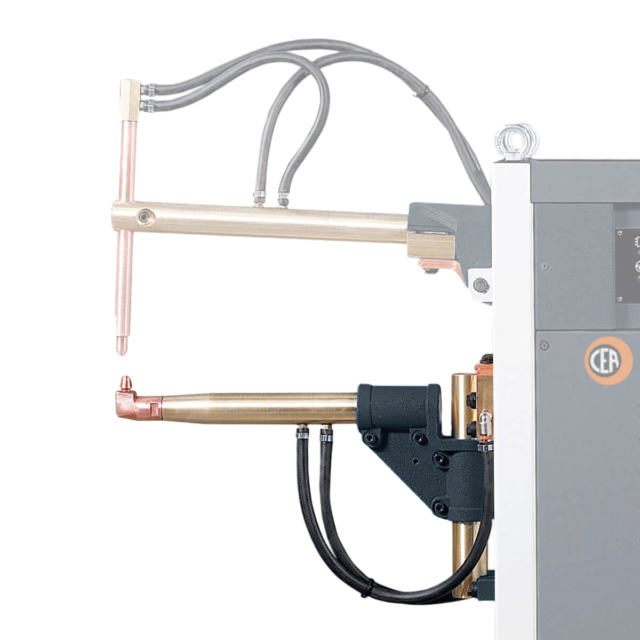

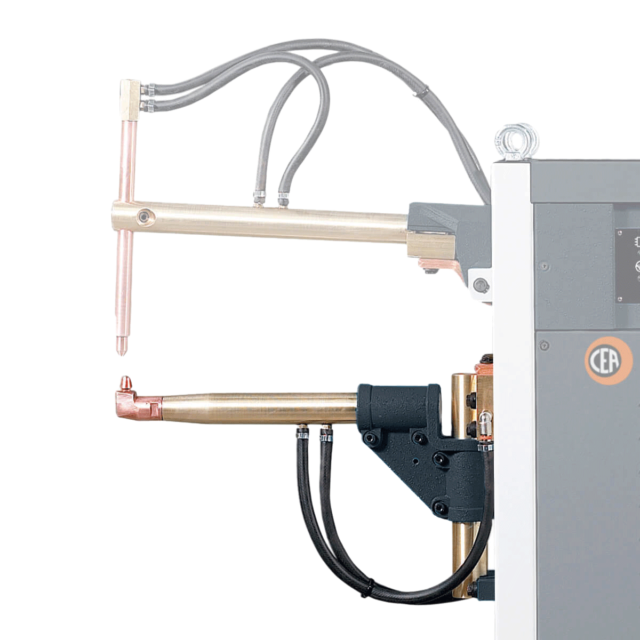

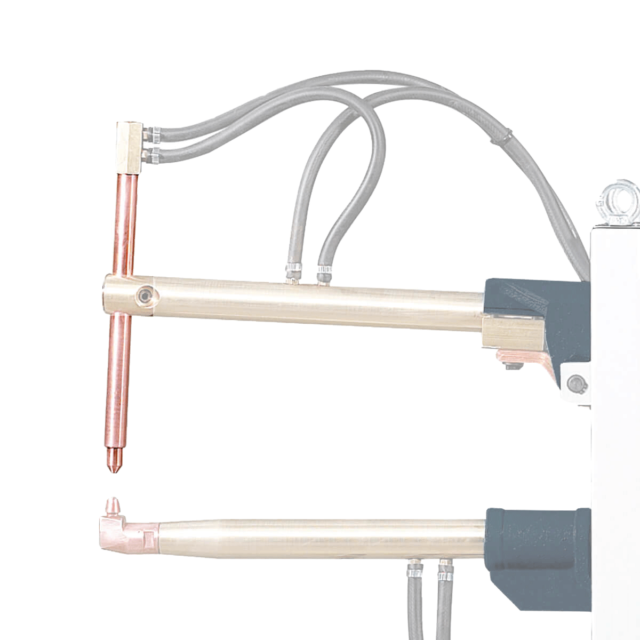

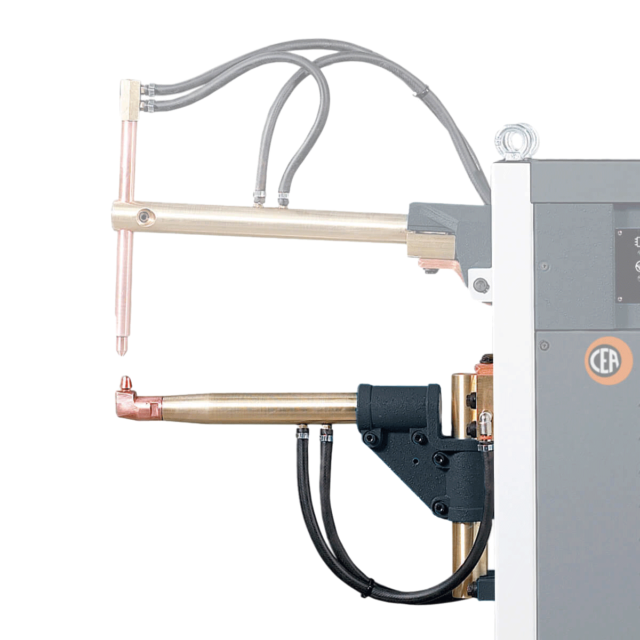

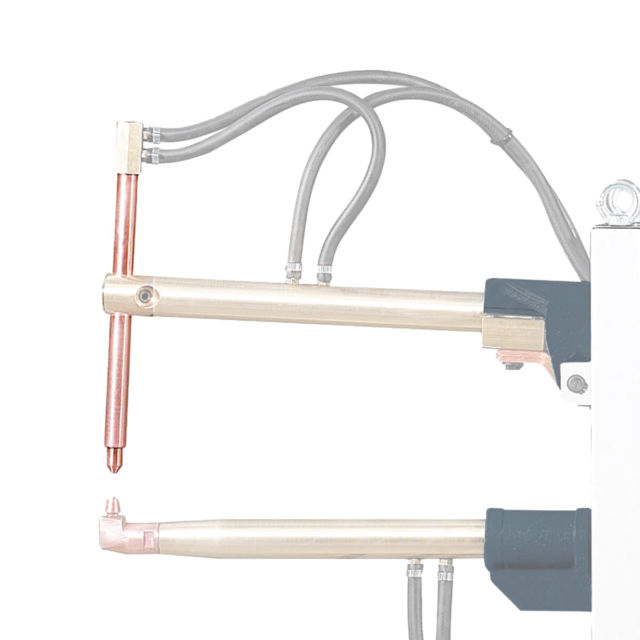

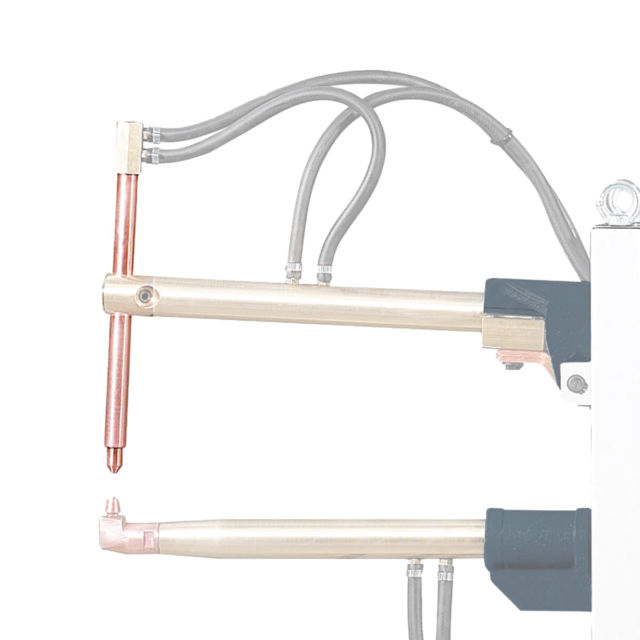

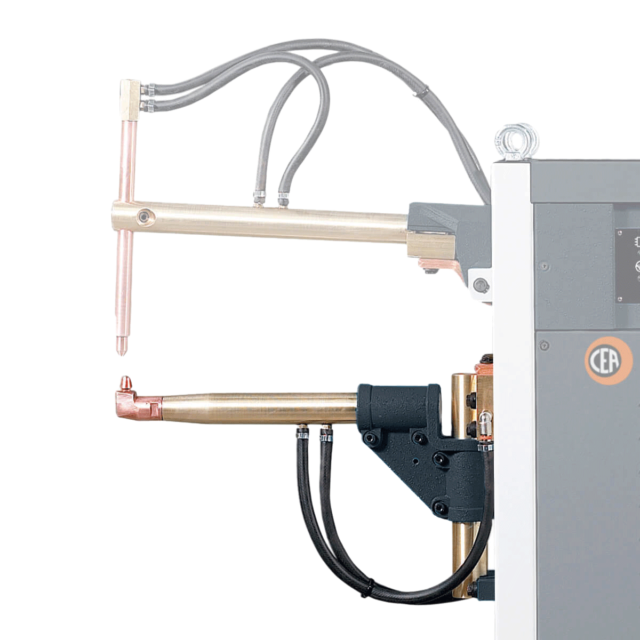

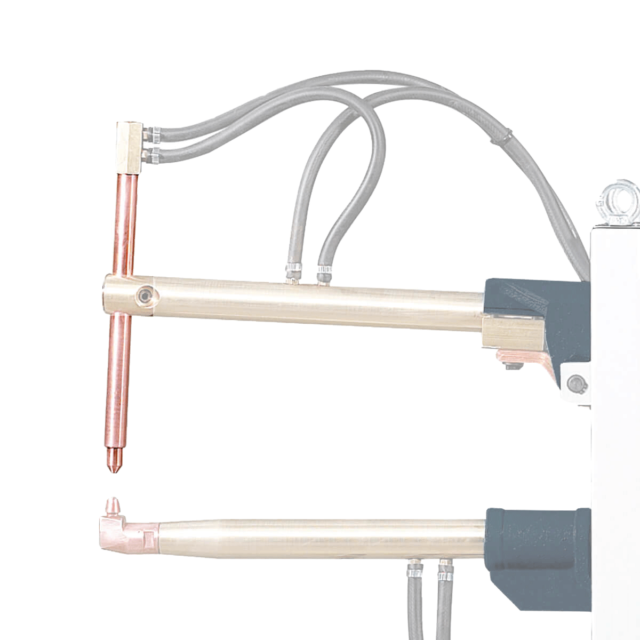

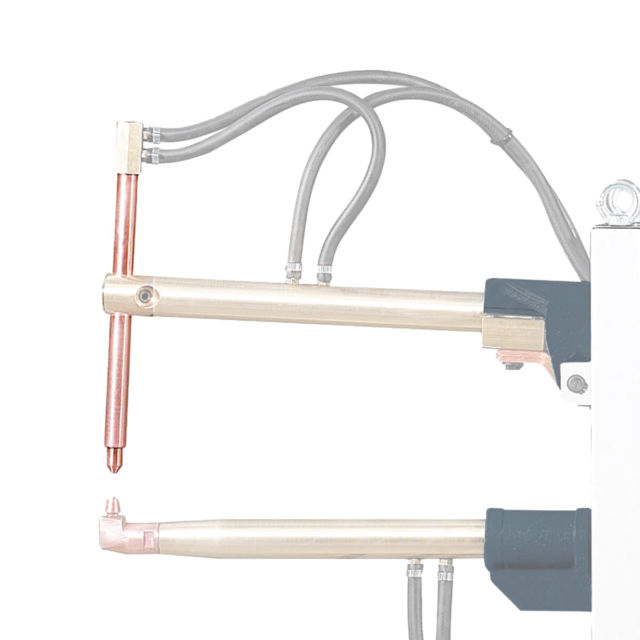

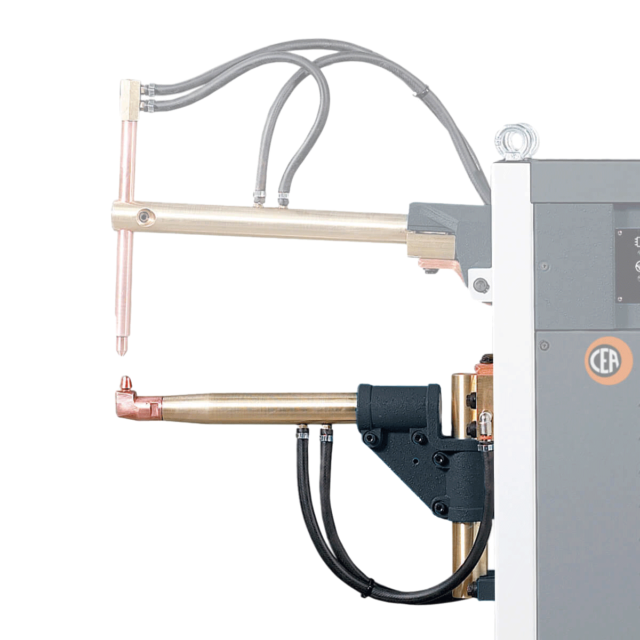

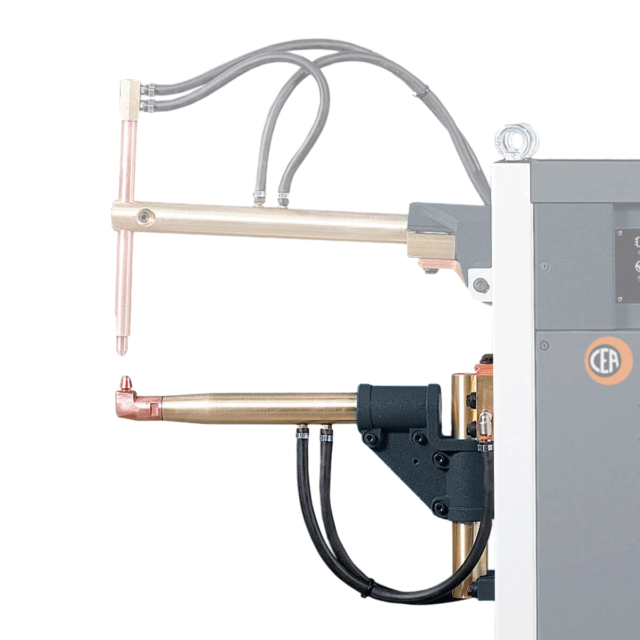

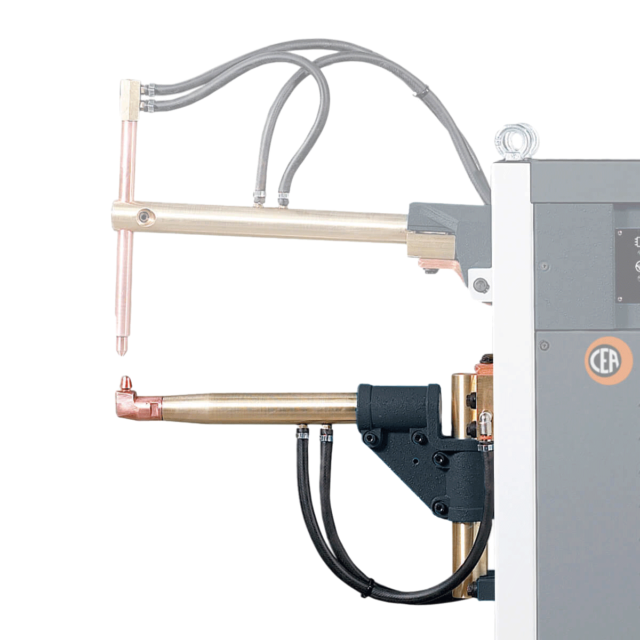

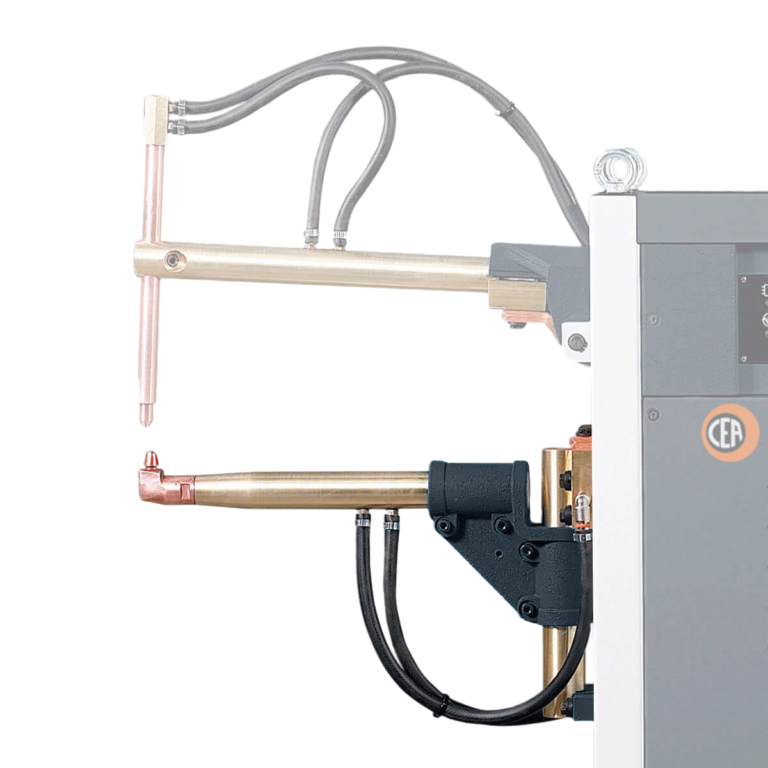

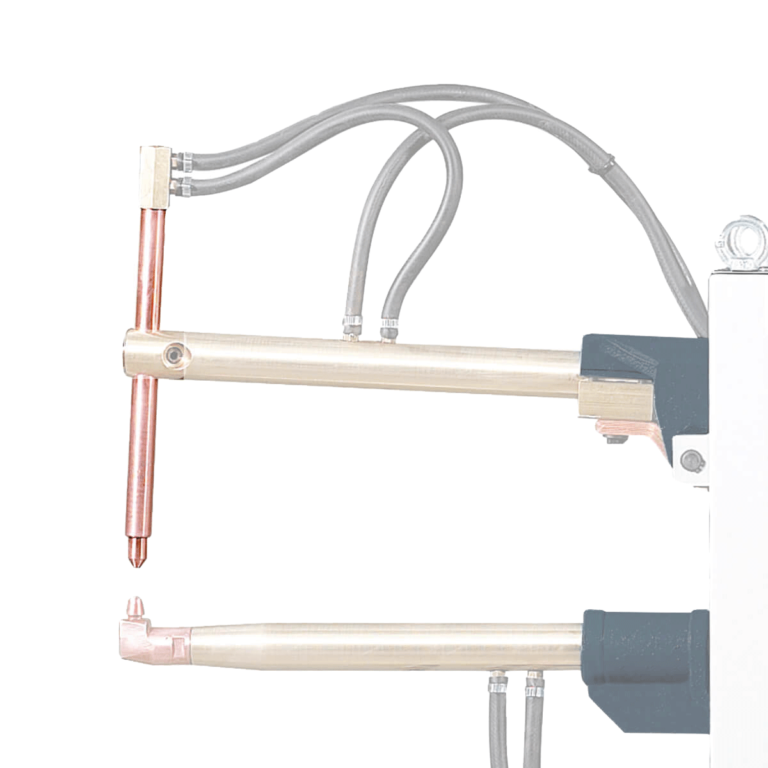

Whenever the lower arm is fitted with a pressed-in

electrode, also a long electrodeholder is necessary on the upper arm.

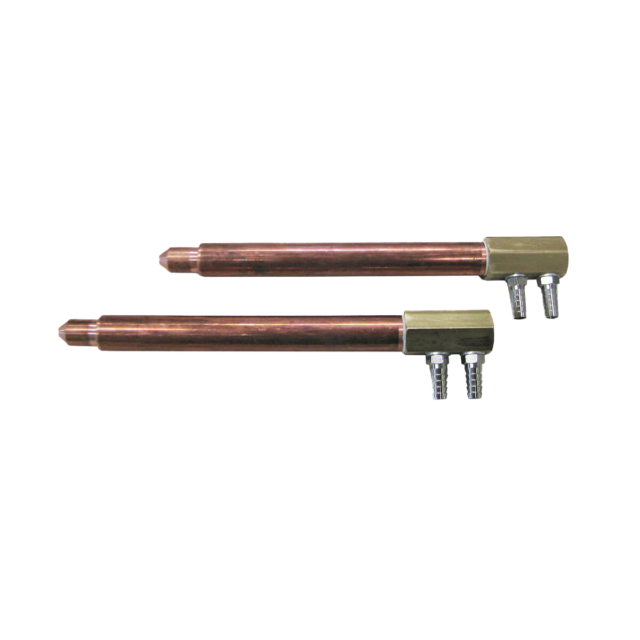

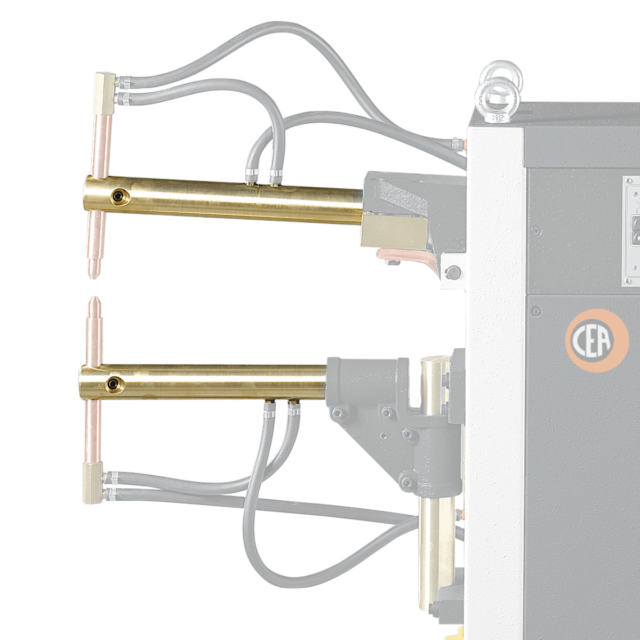

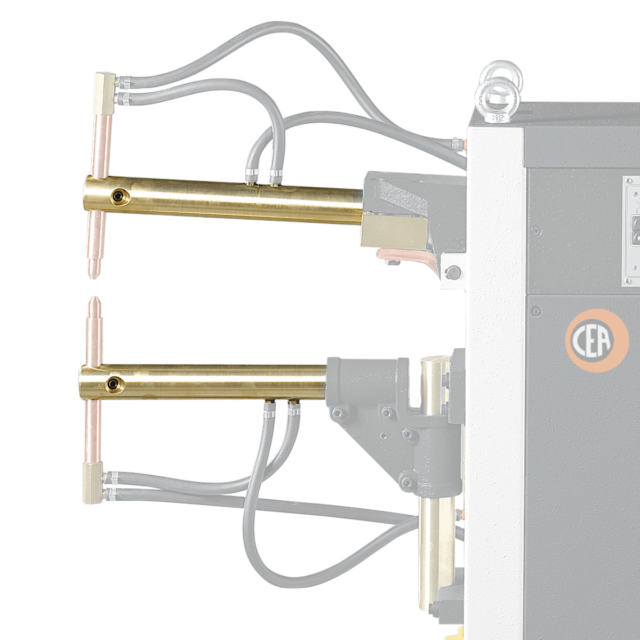

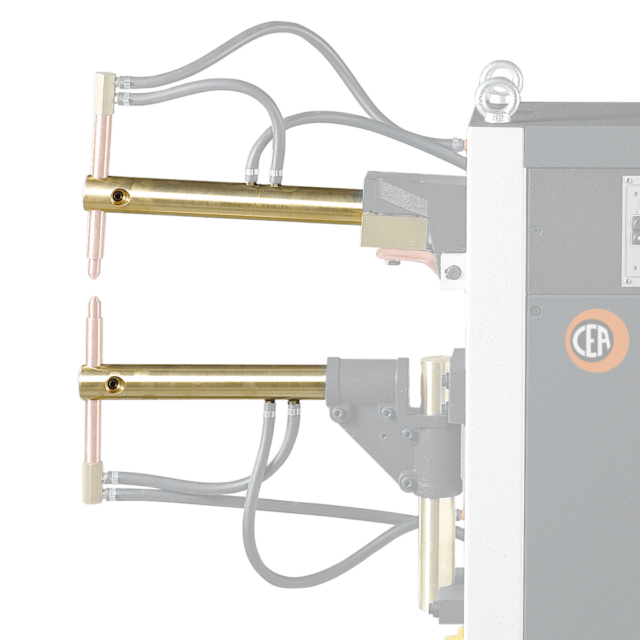

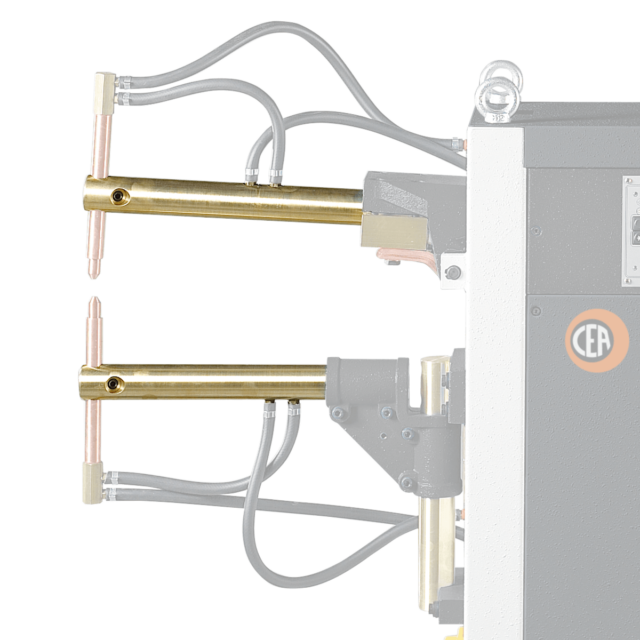

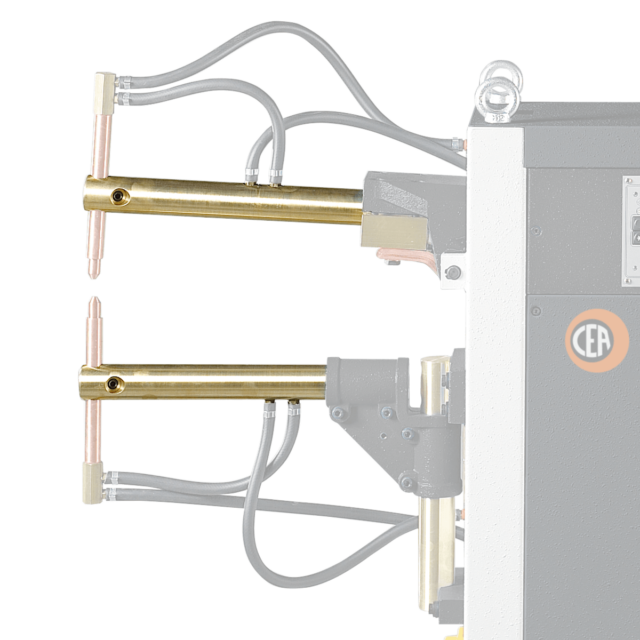

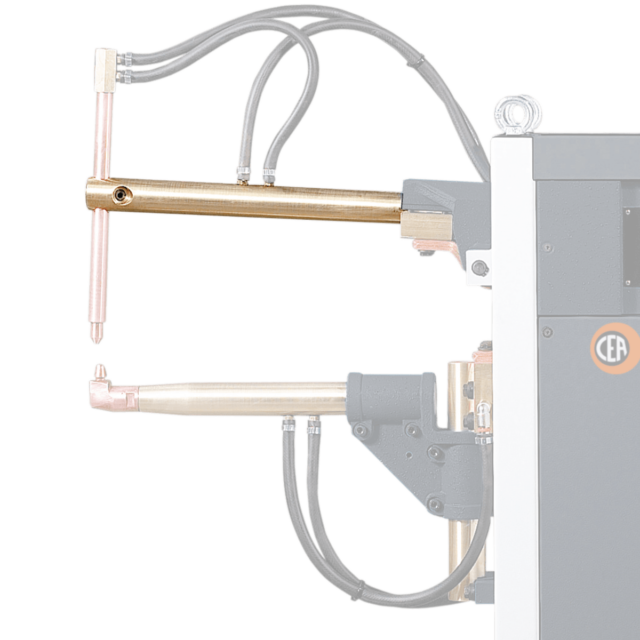

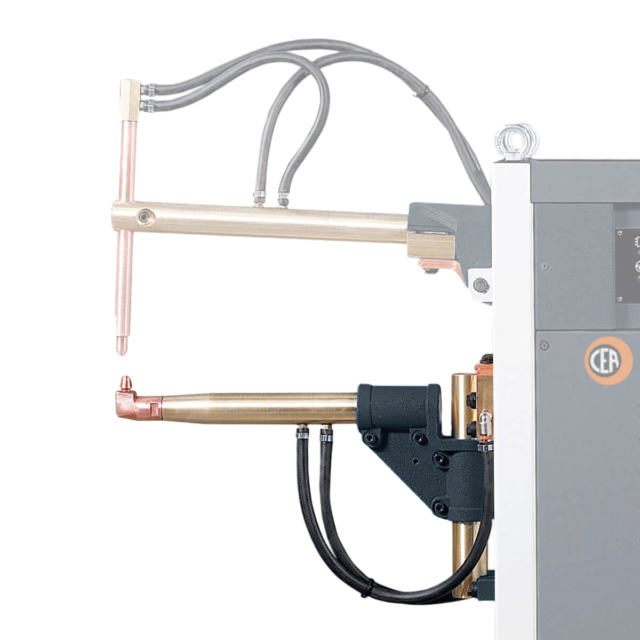

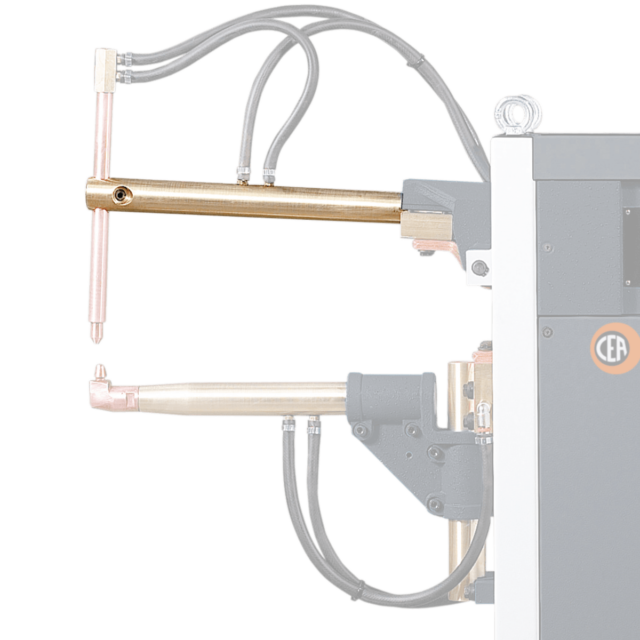

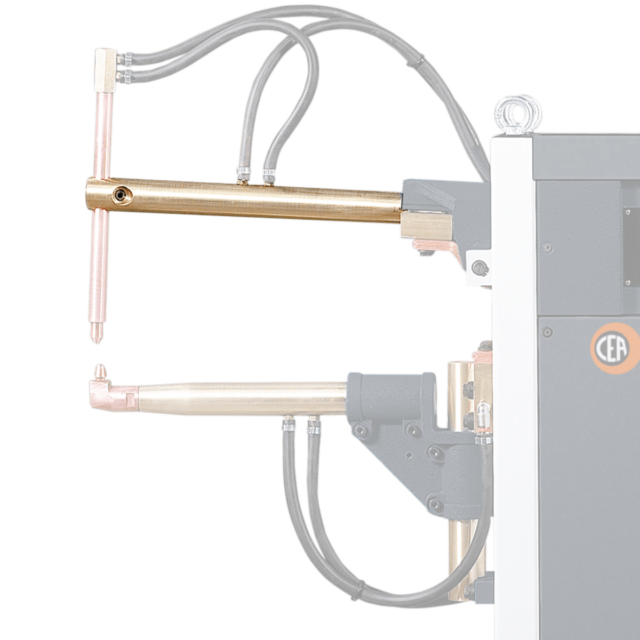

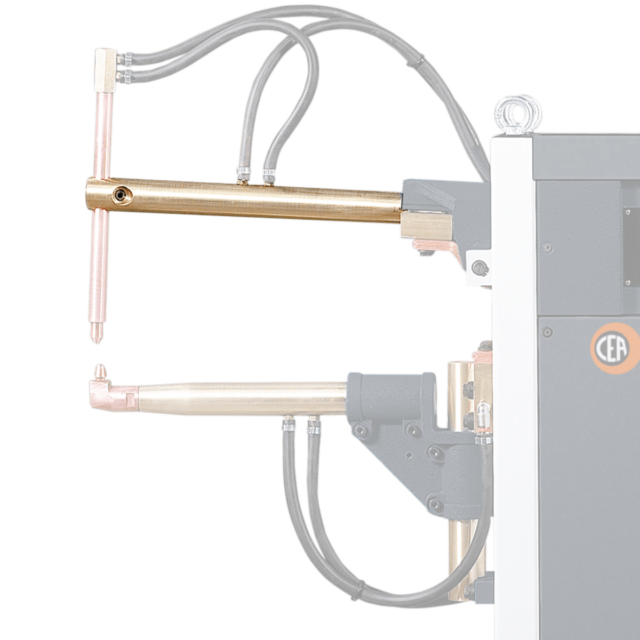

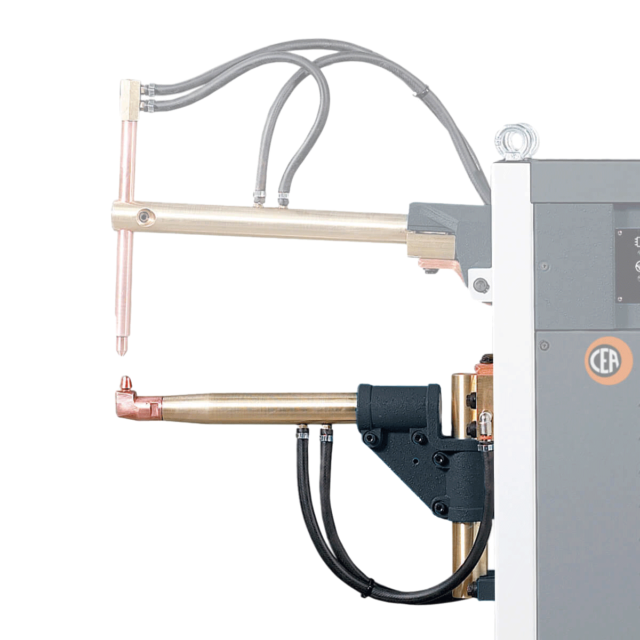

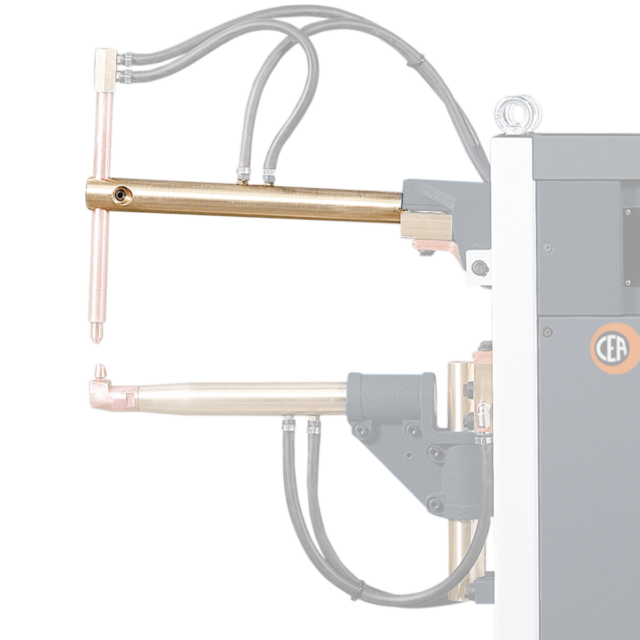

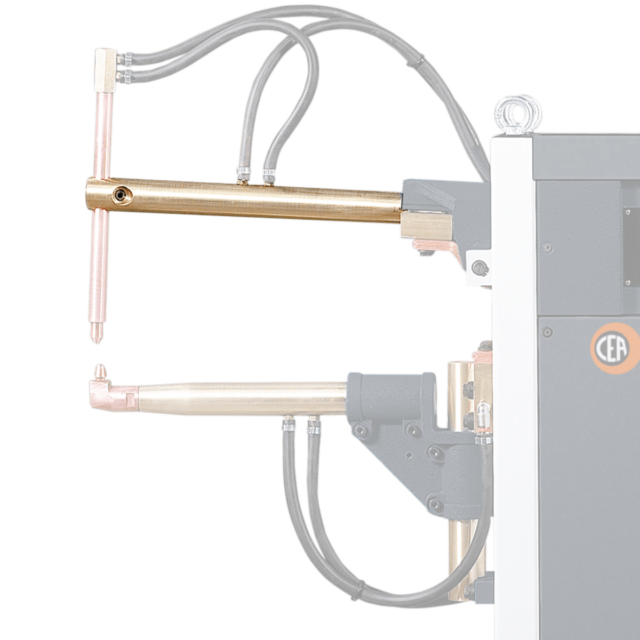

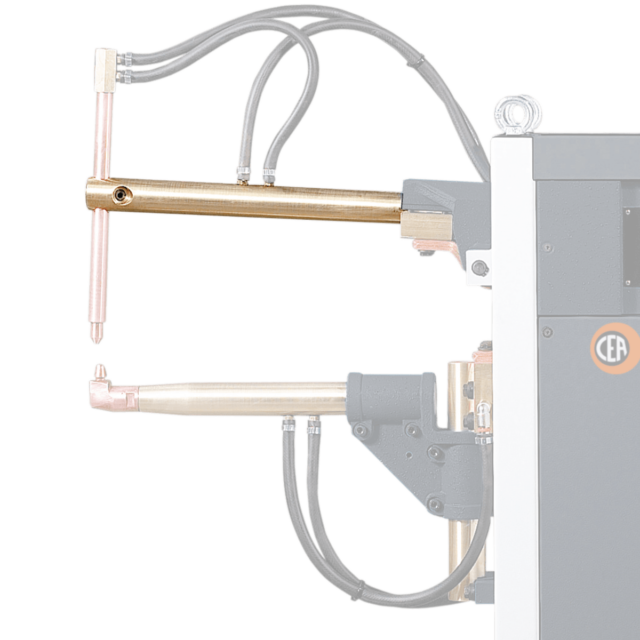

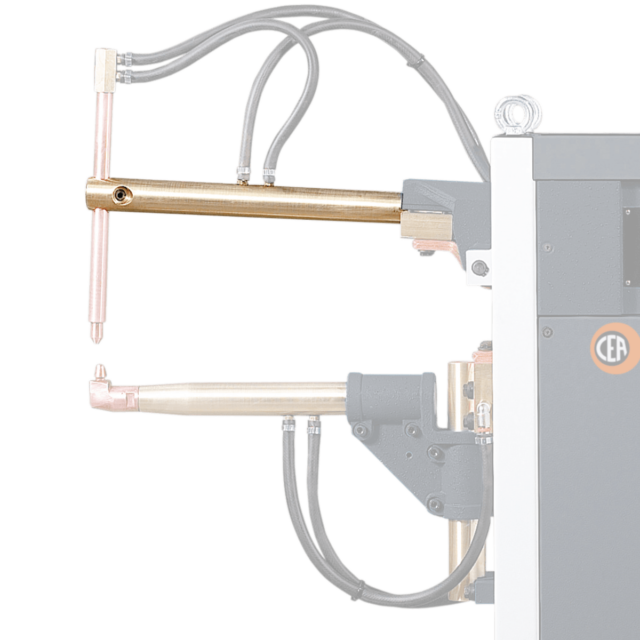

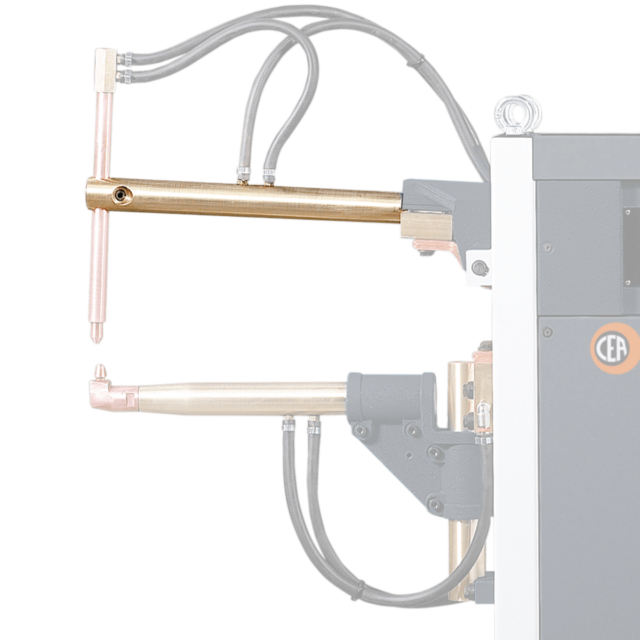

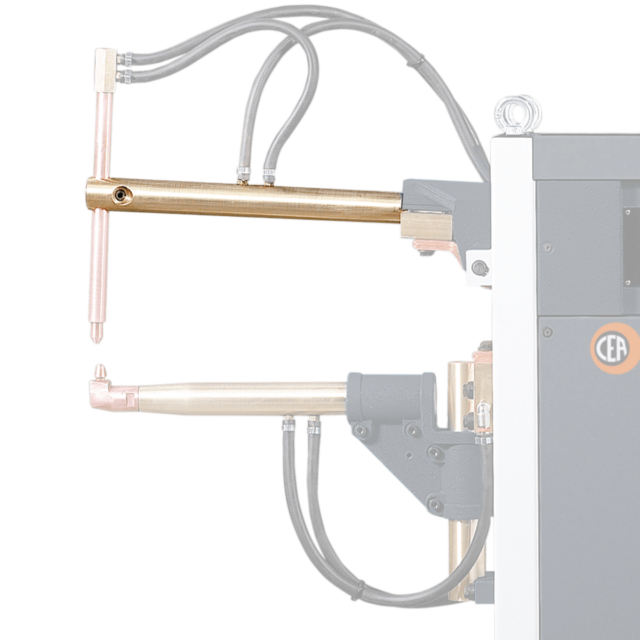

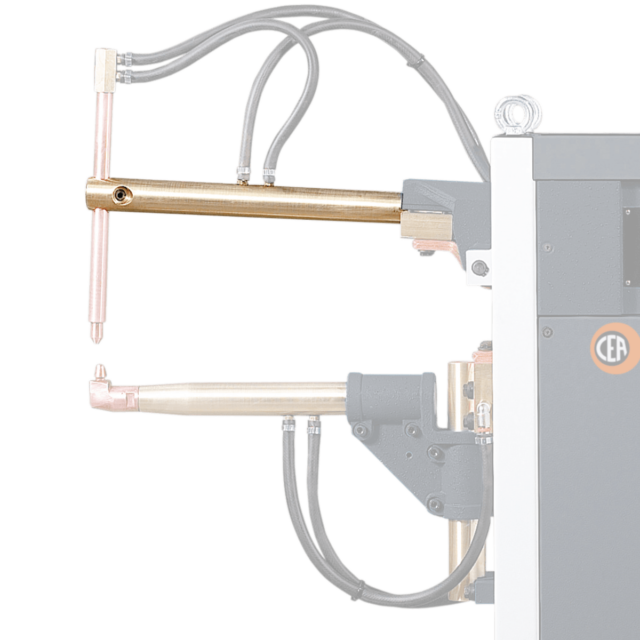

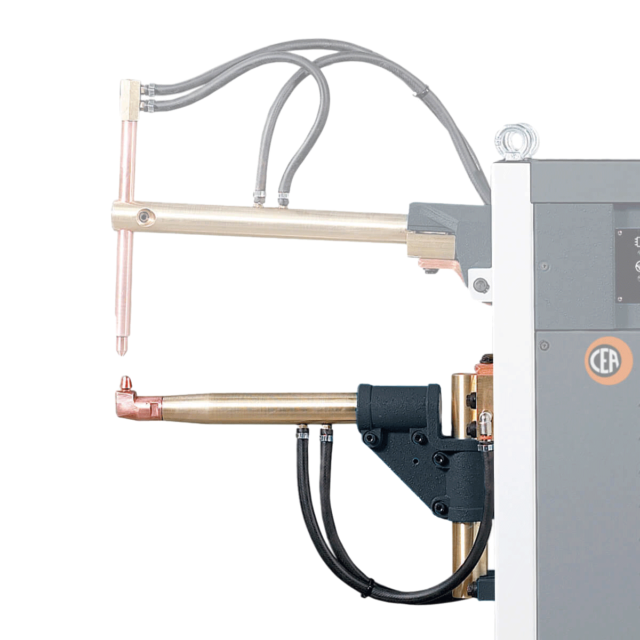

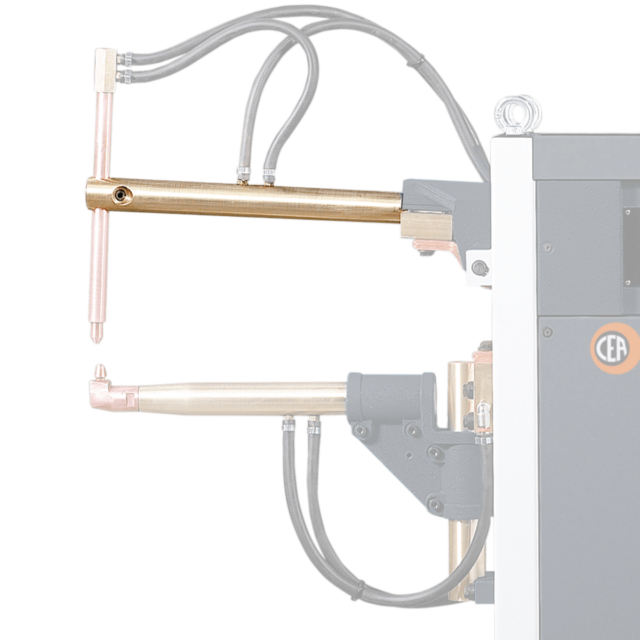

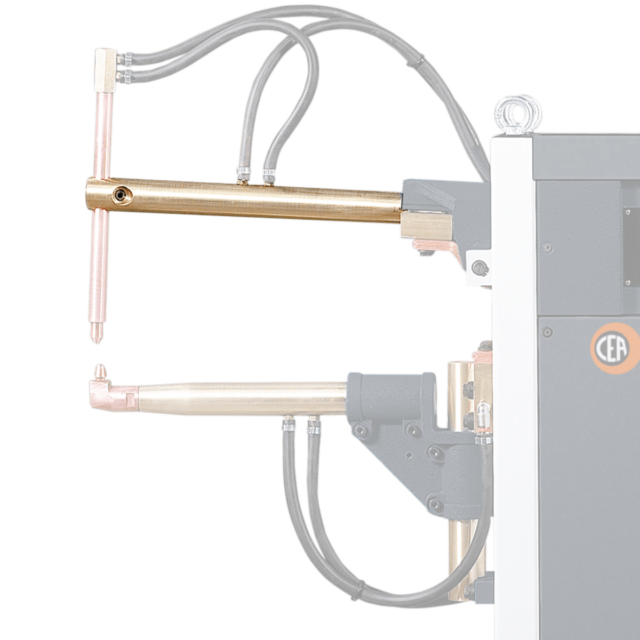

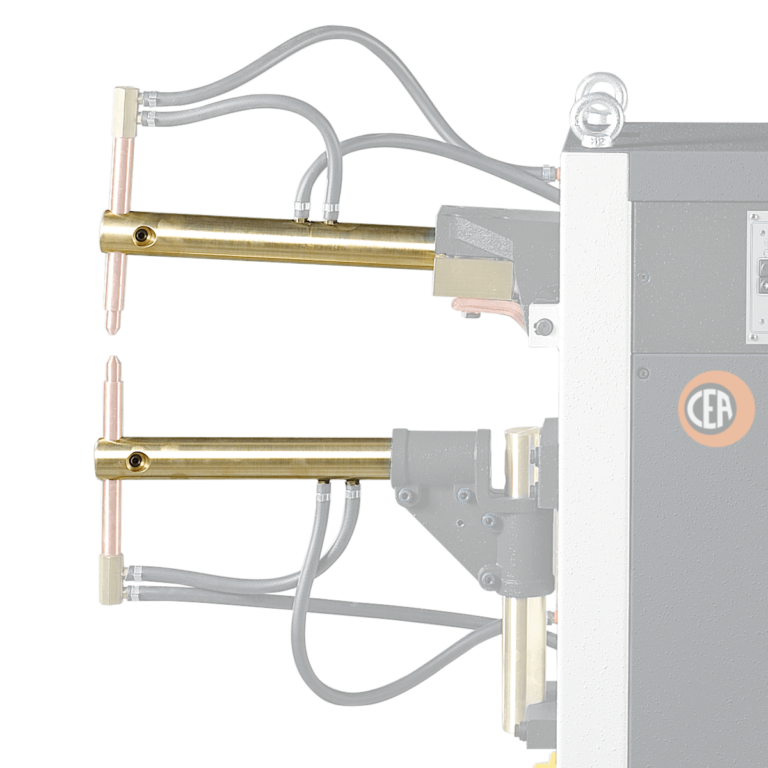

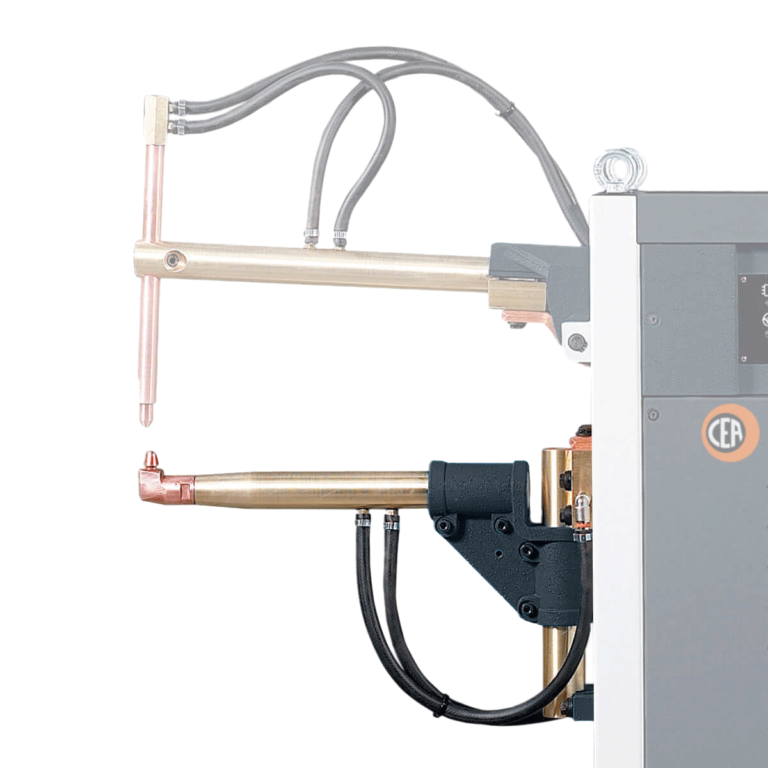

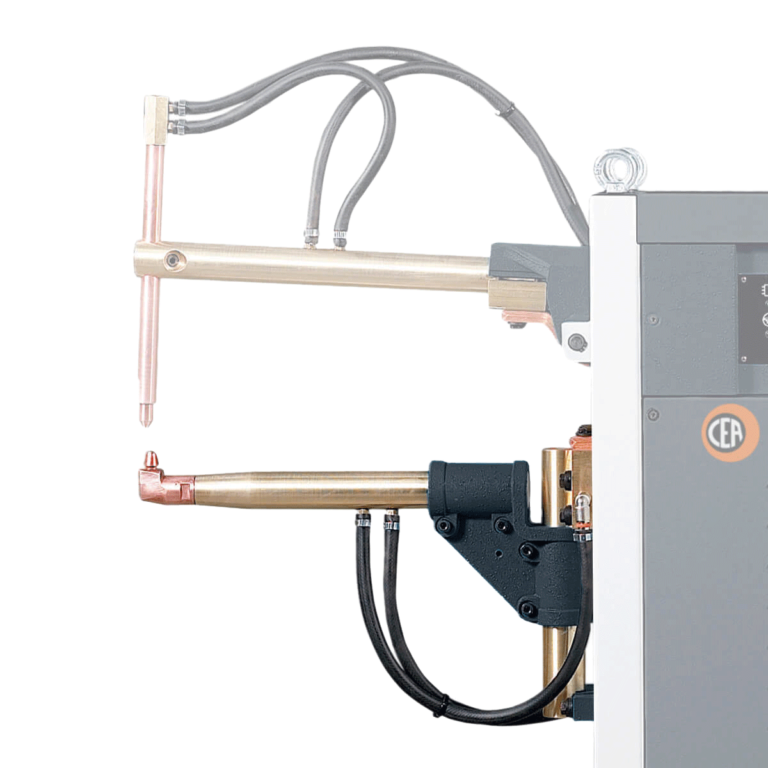

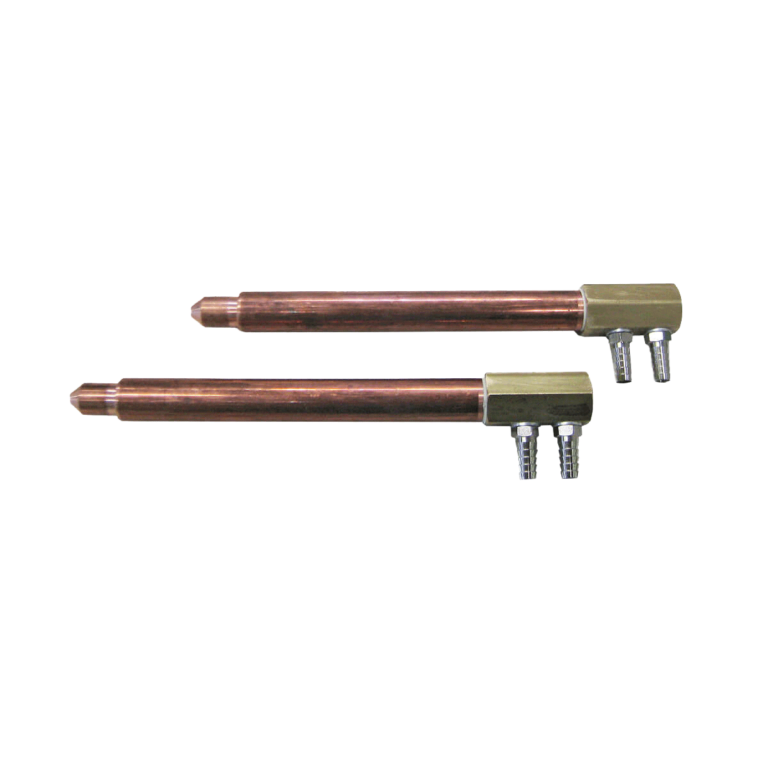

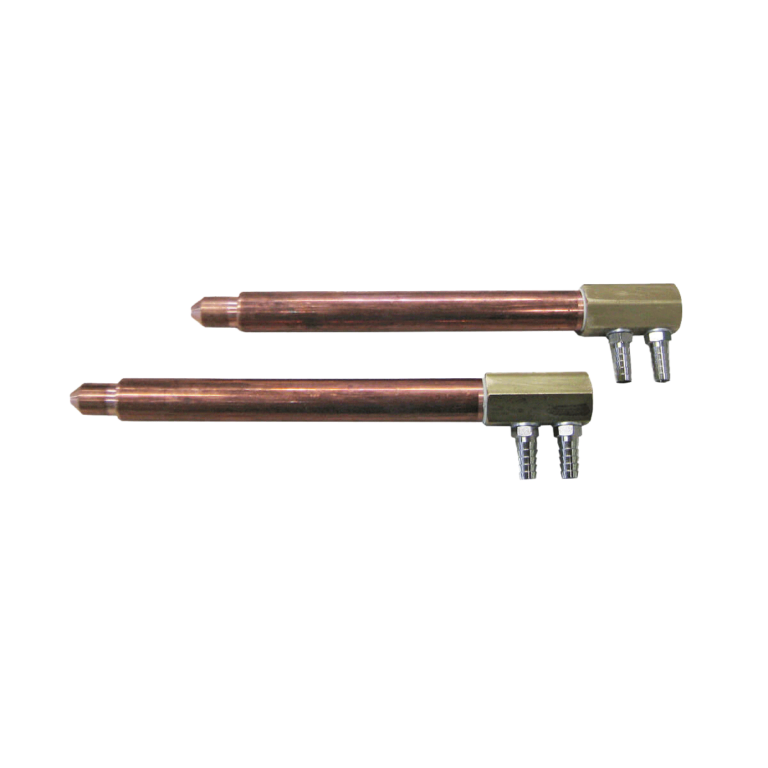

Set of arms 455 mm cooled Ø 40 mm

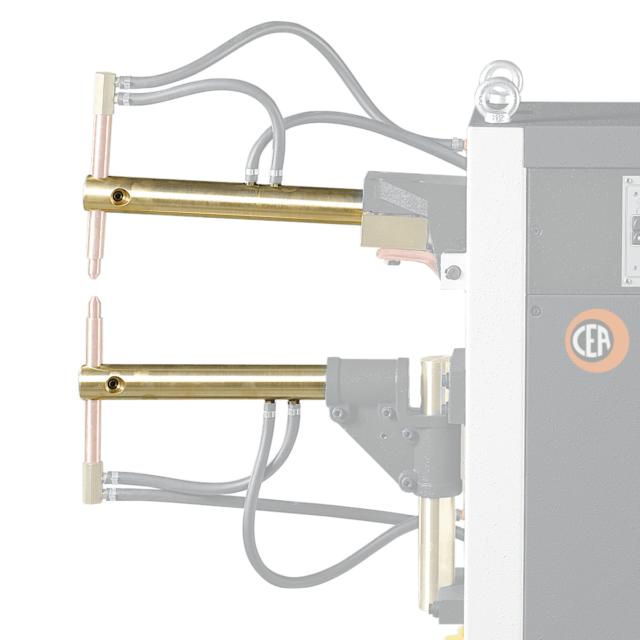

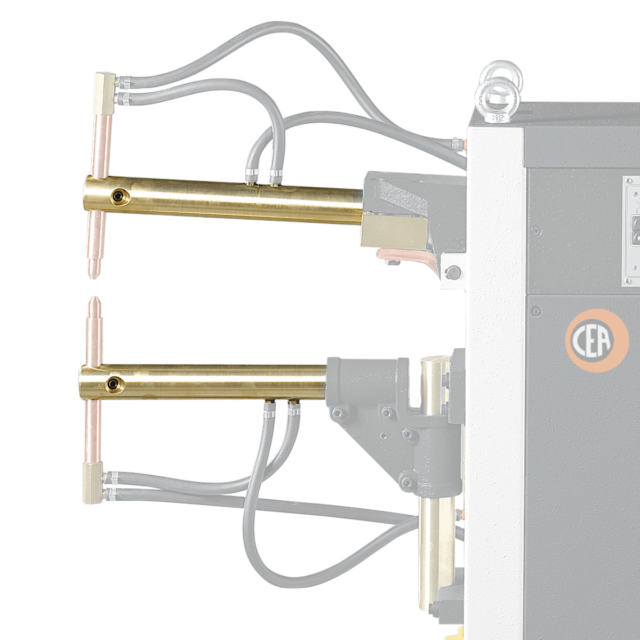

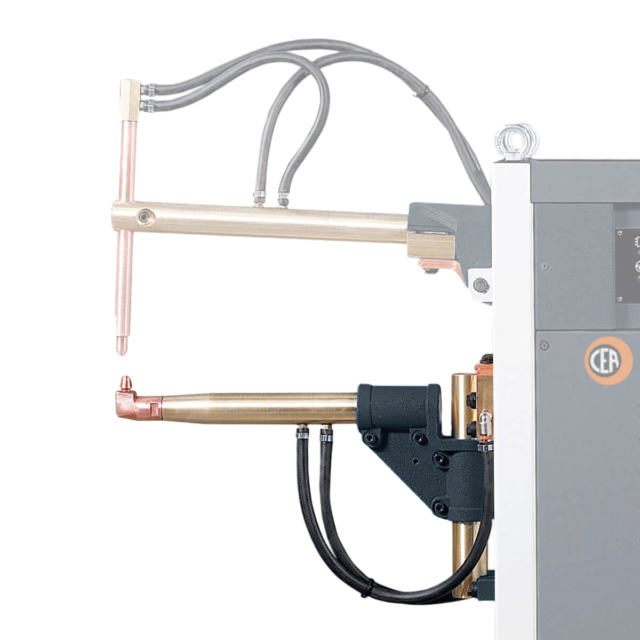

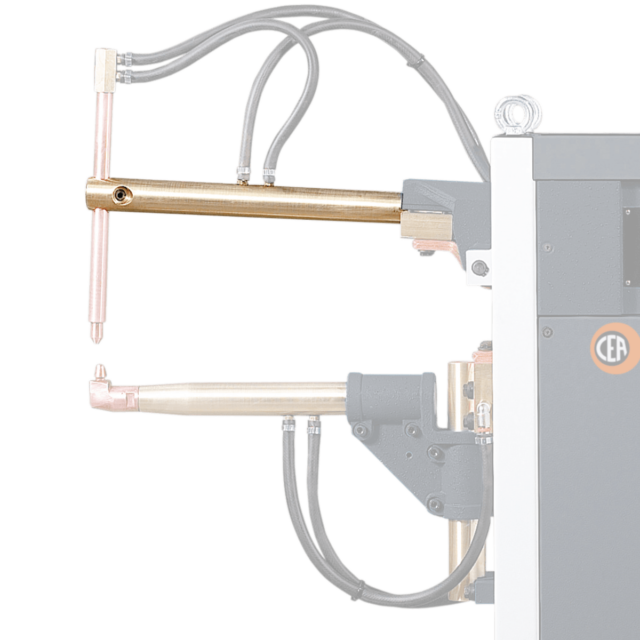

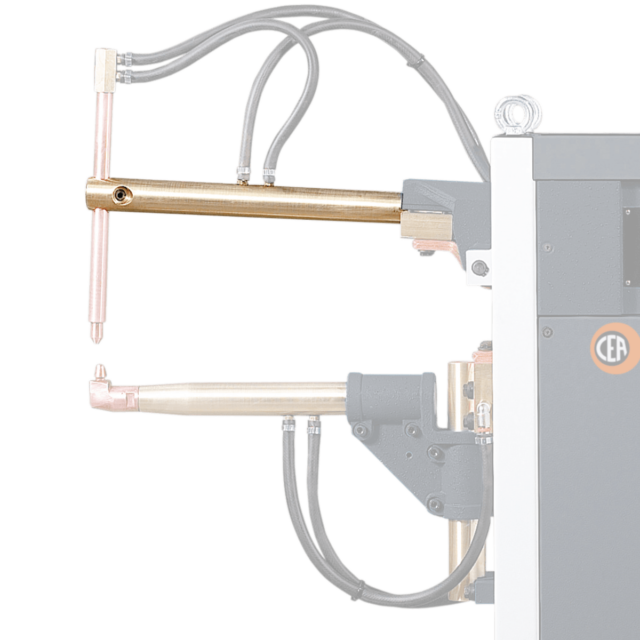

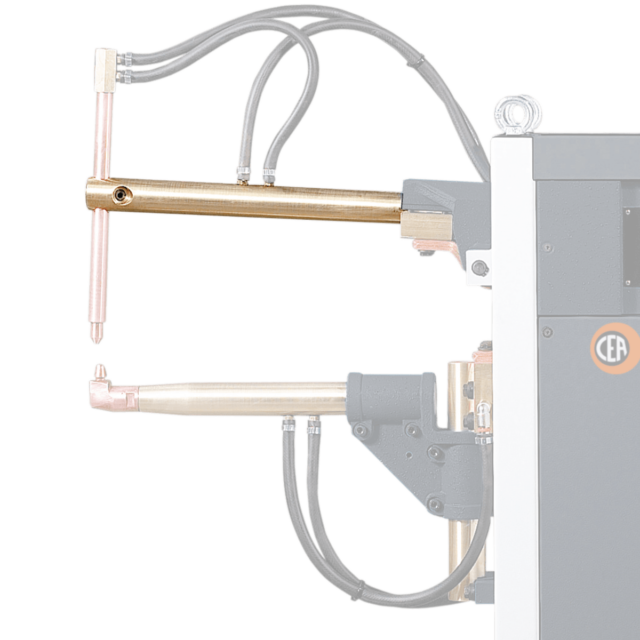

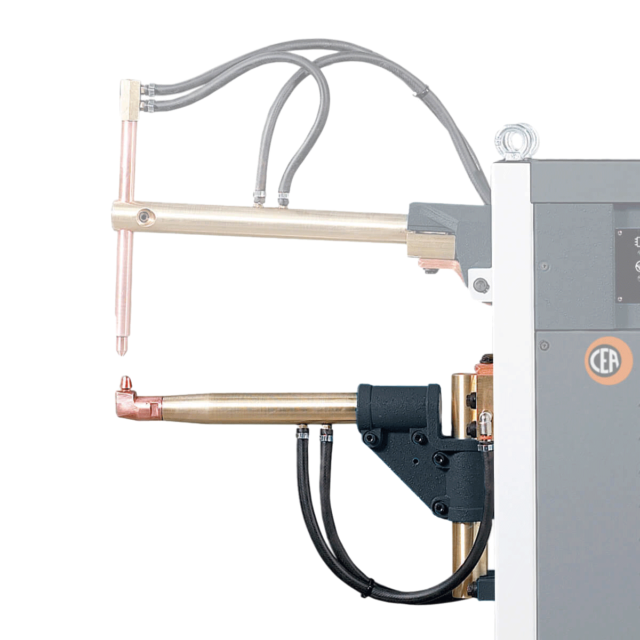

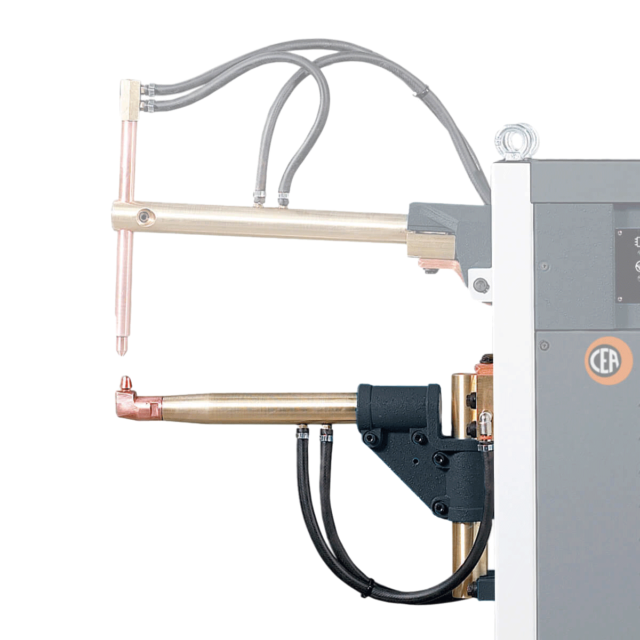

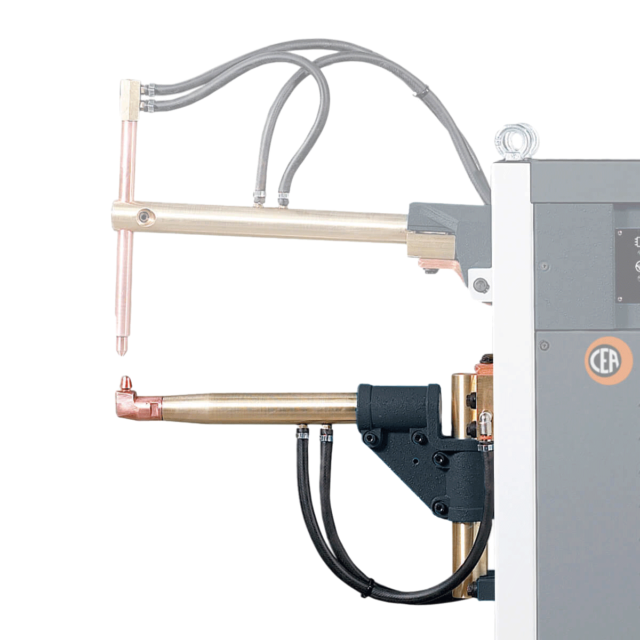

Set of arms 600 mm cooled Ø 40 mm

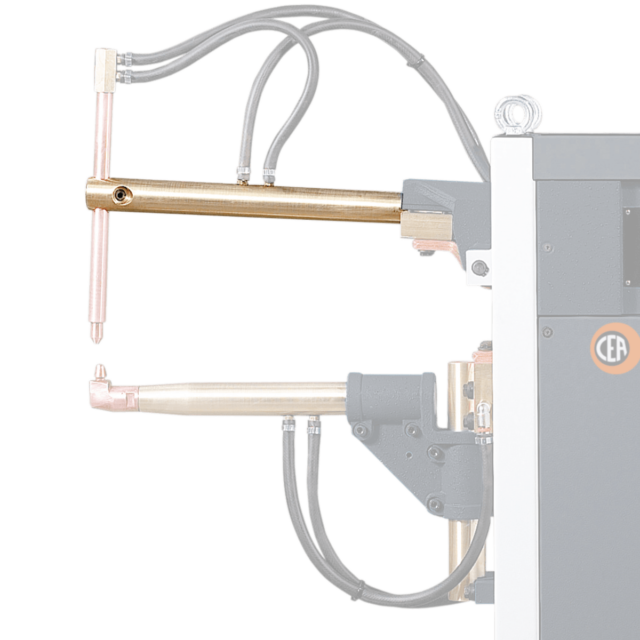

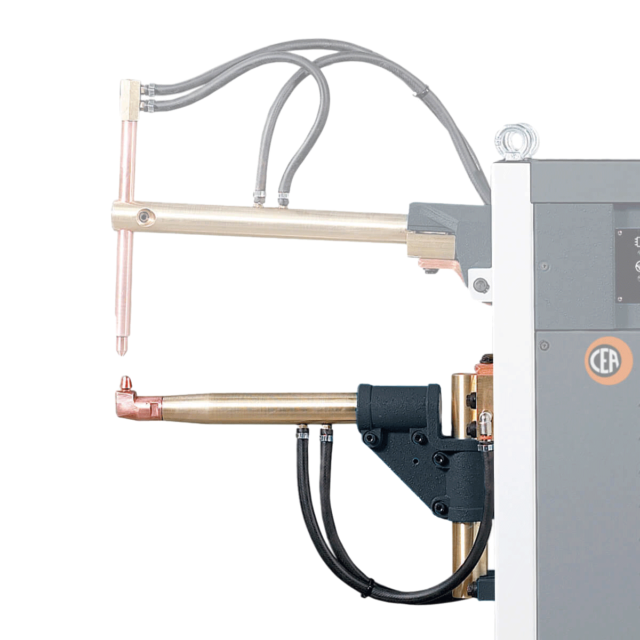

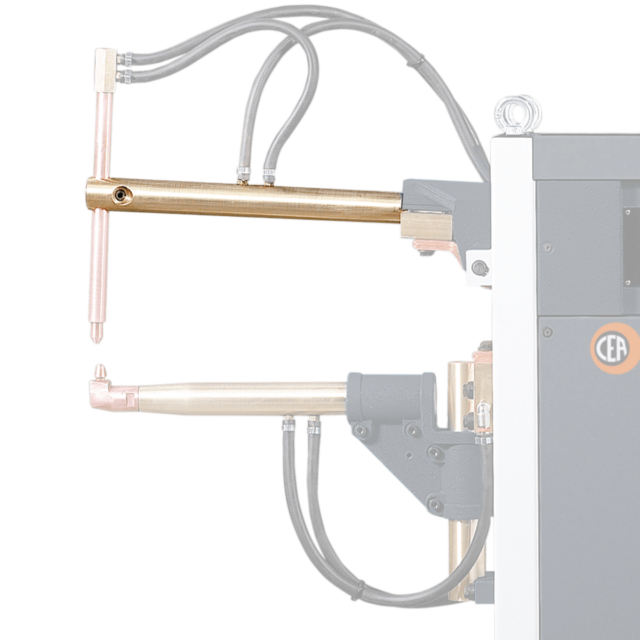

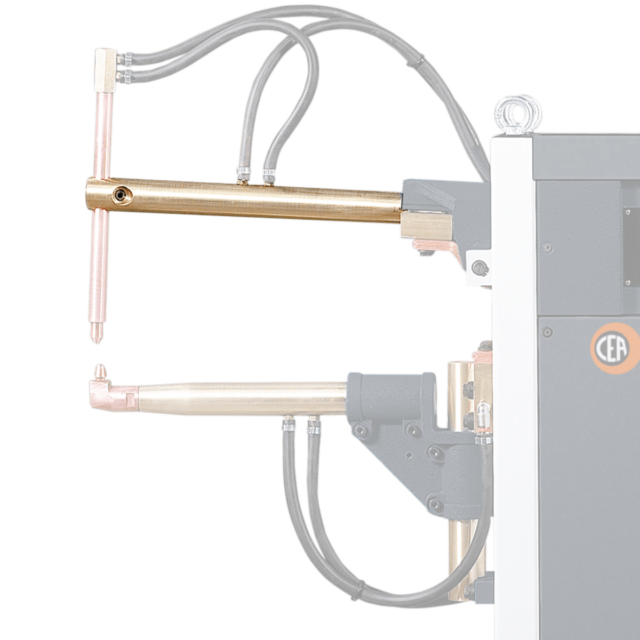

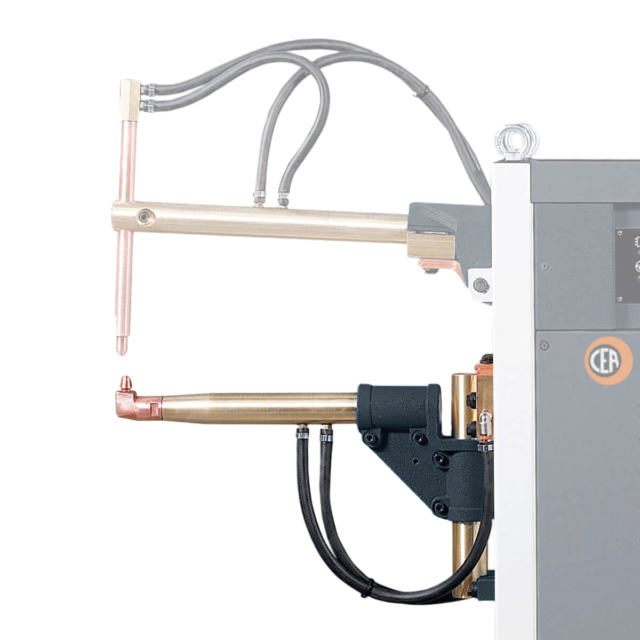

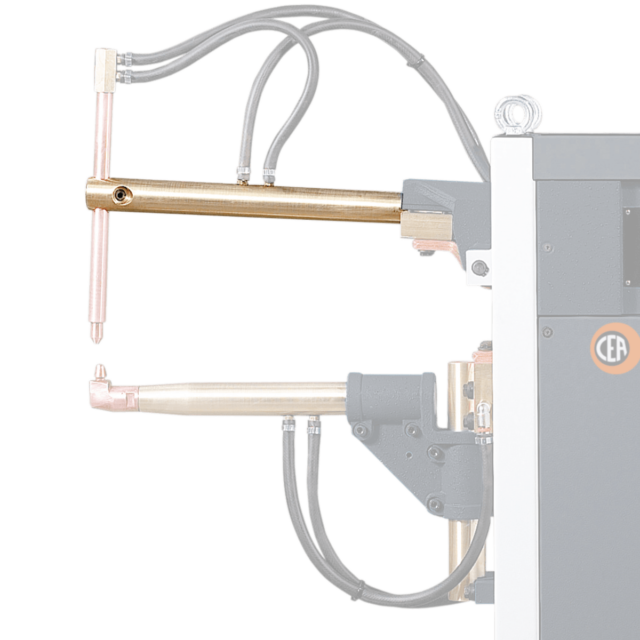

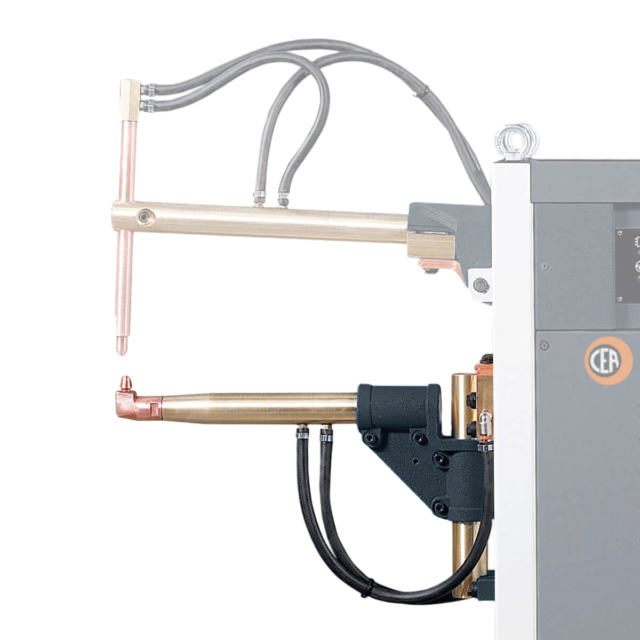

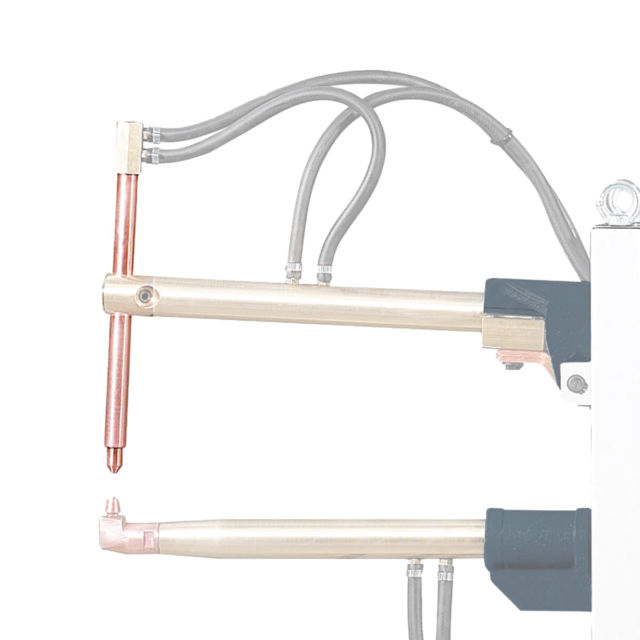

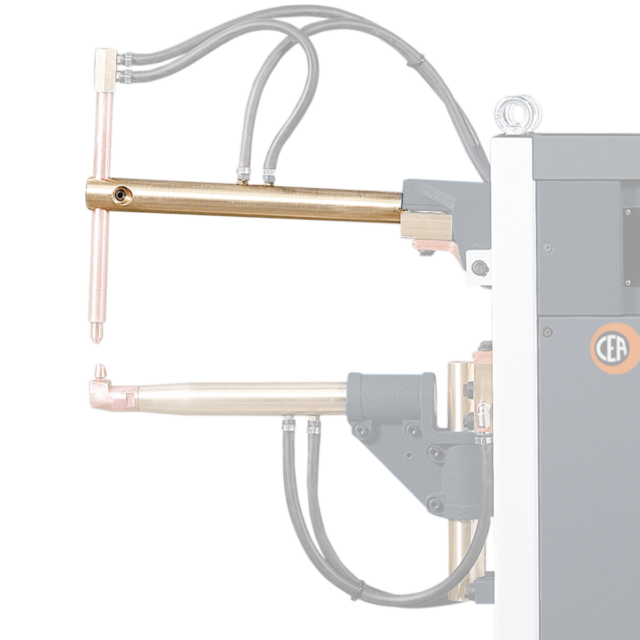

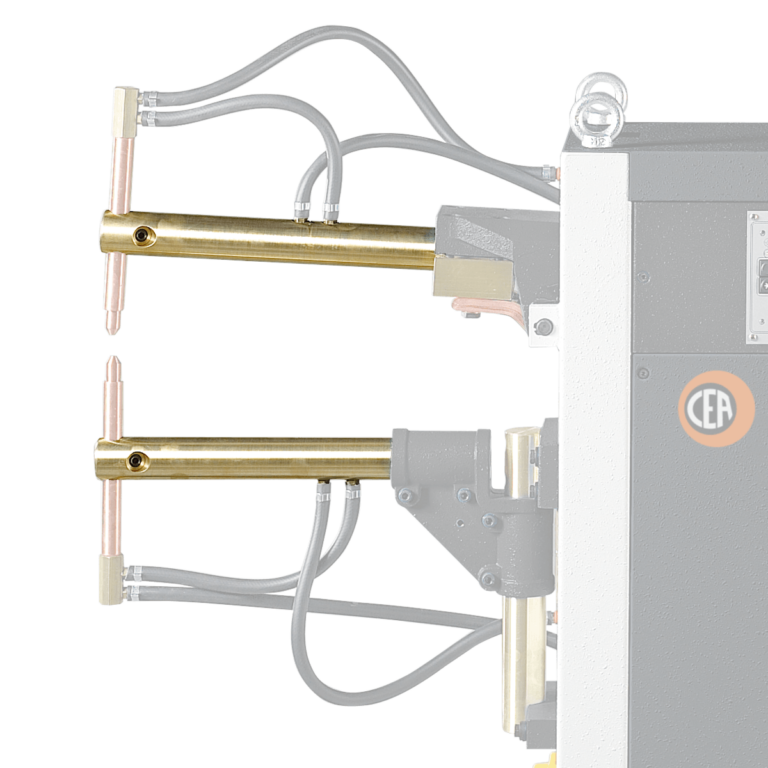

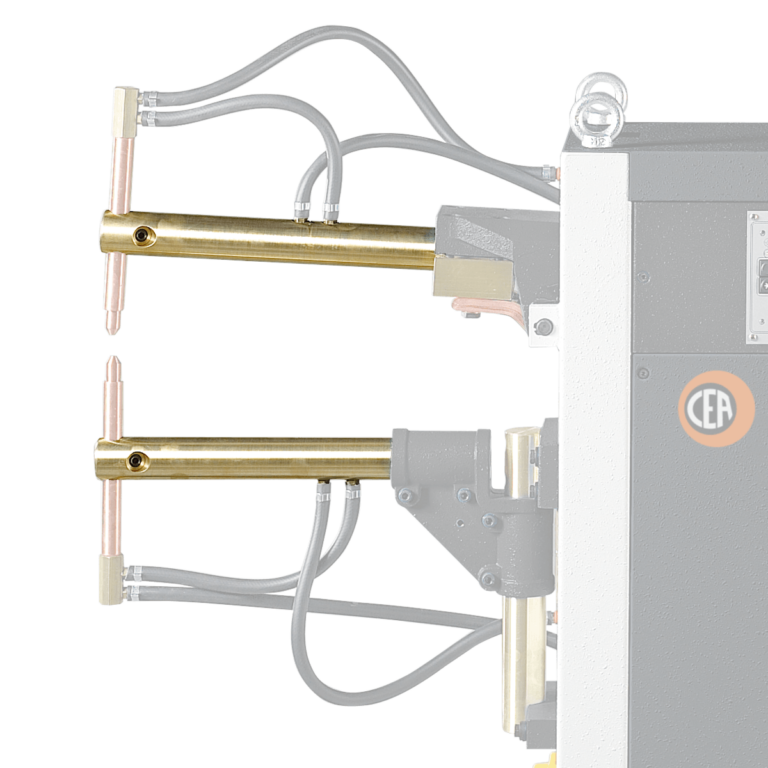

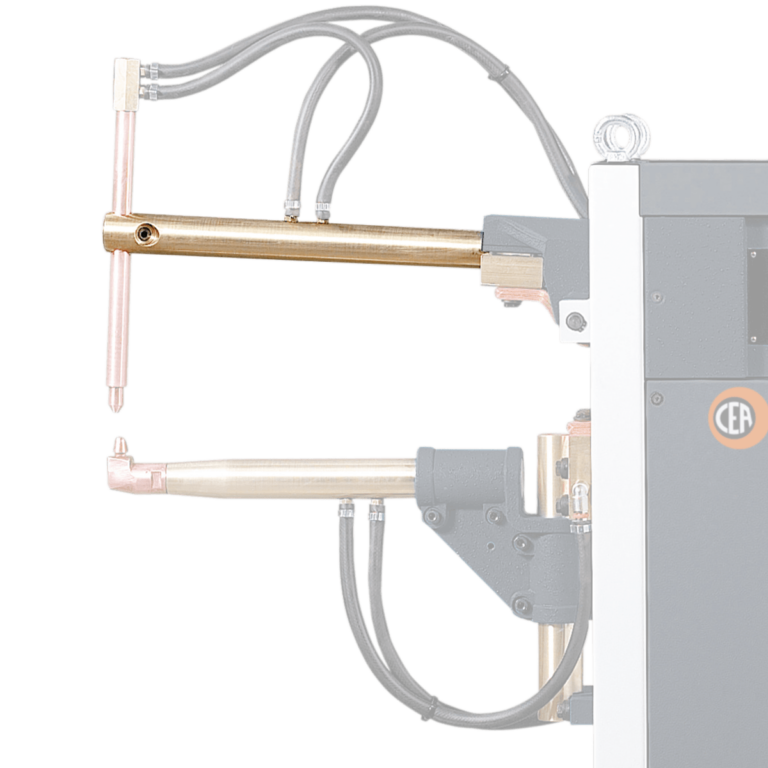

Set of arms 455 mm cooled Ø 45 mm

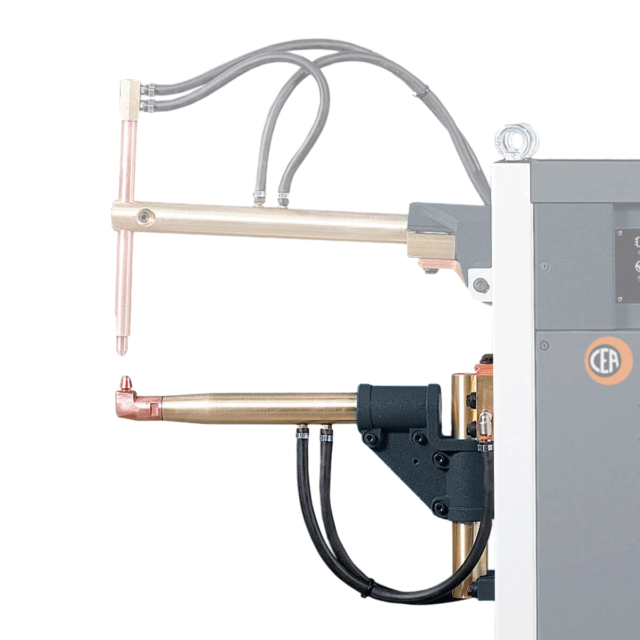

Set of arms 800 mm cooled Ø 45 mm

Set of arms 1000 mm cooled Ø 50 mm

Set of arms 490 mm cooled Ø 50 mm

Set of arms 700 mm cooled Ø 50 mm

Upper Arm Length: 455 mm Ø: 40mm

Inferior Straight Arm 455 mm (Useful Length: 200 mm)

Upper Arm Length: 600 mm Ø: 40mm

Inferior Straight Arm 600 mm (Useful Length: 345 mm)

Upper Arm Length: 455 mm Ø: 45mm

Inferior Straight Arm 455 mm (Useful Length: 200 mm)

Upper Arm Length: 800 mm Ø: 45mm

Inferior Straight Arm 800 mm (Useful Length: 545 mm)

Upper Arm Length: 490 mm Ø: 50 mm

Inferior Straight Arm 490 mm (Useful Length: 205 mm)

Upper Arm Length: 700 mm Ø: 50mm

Inferior Straight Arm 700 mm (Useful Length: 415 mm)

Upper Arm Length: 1000 mm Ø: 50mm

Inferior Straight Arm 1000 mm (Useful Length: 715 mm)

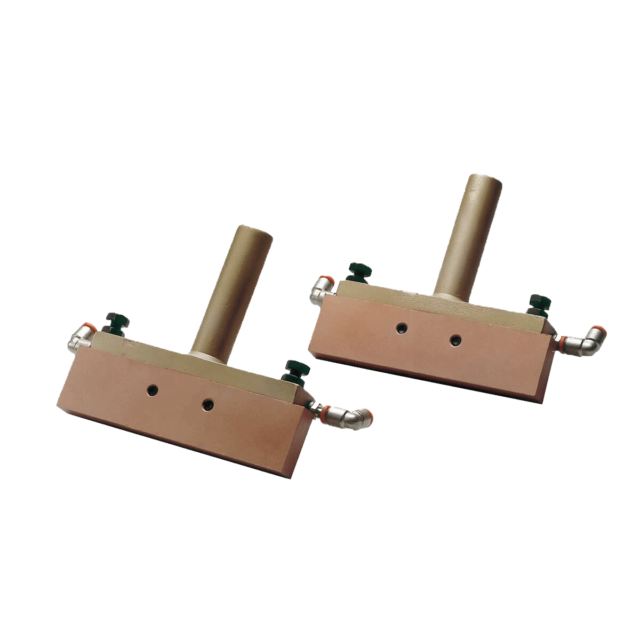

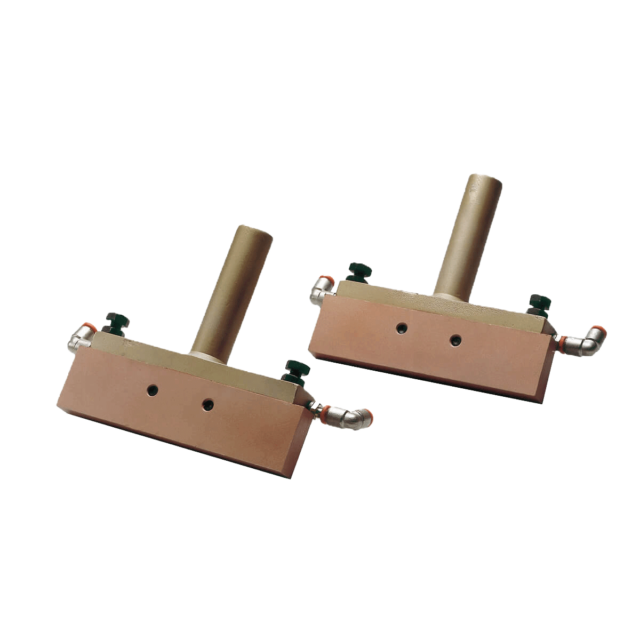

Water cooling equipment IR 14 400 V

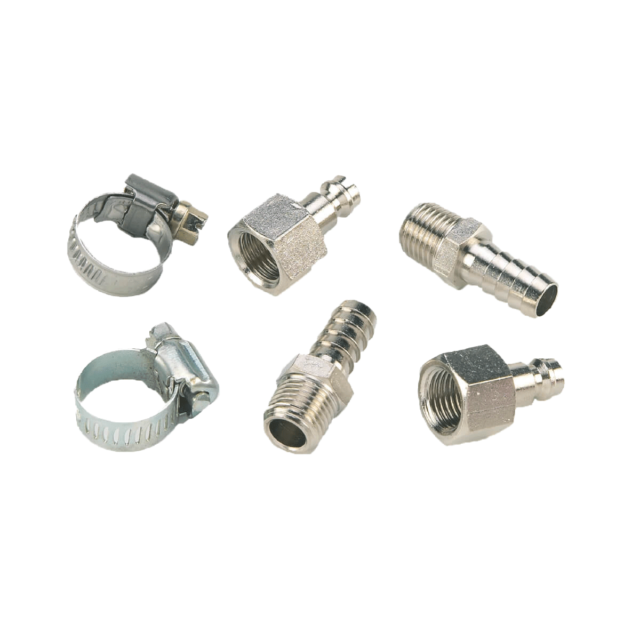

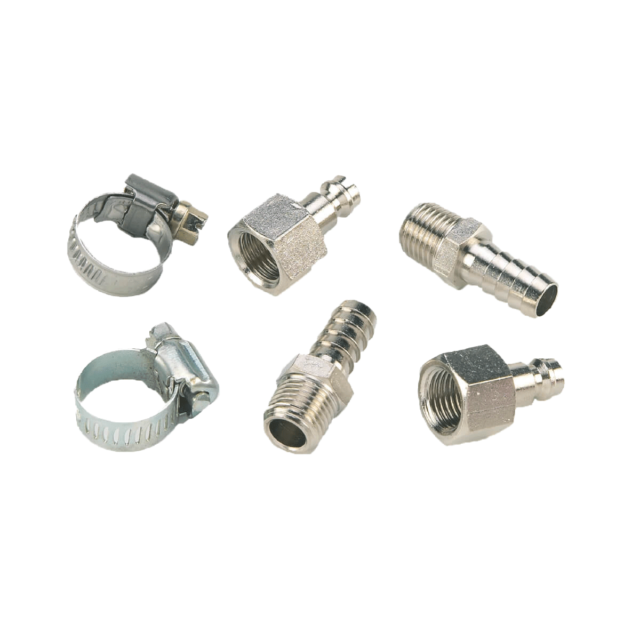

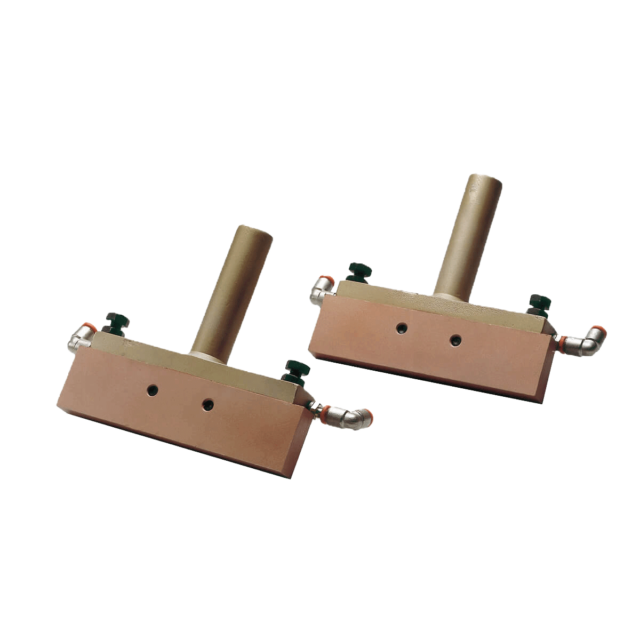

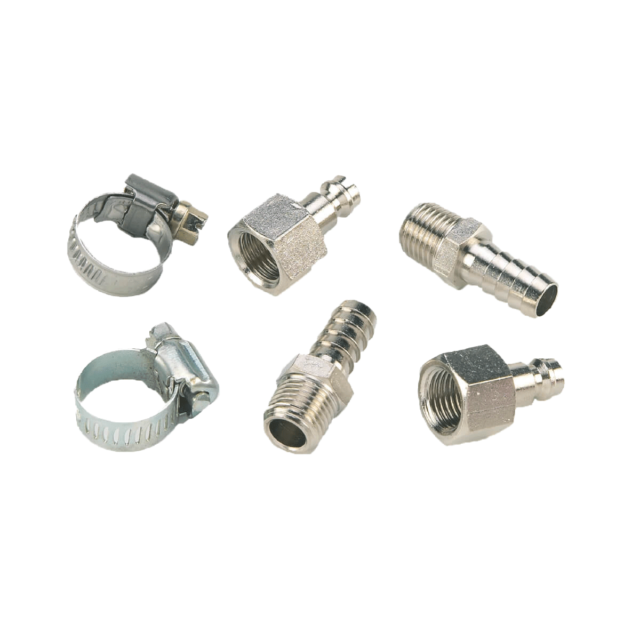

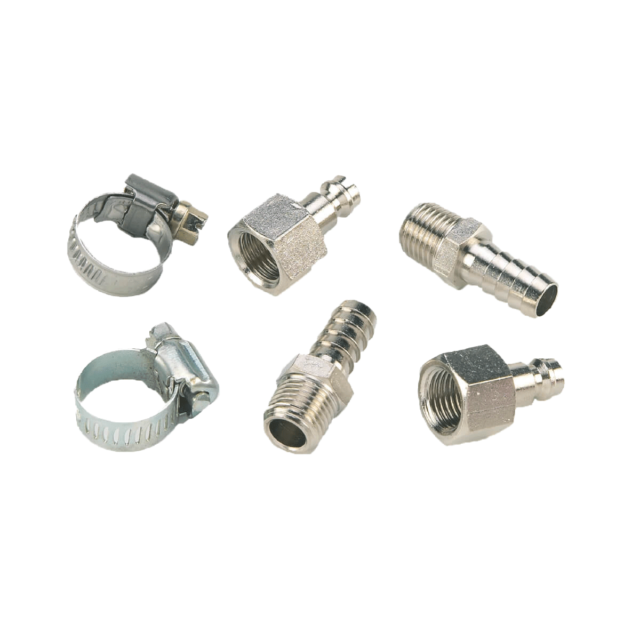

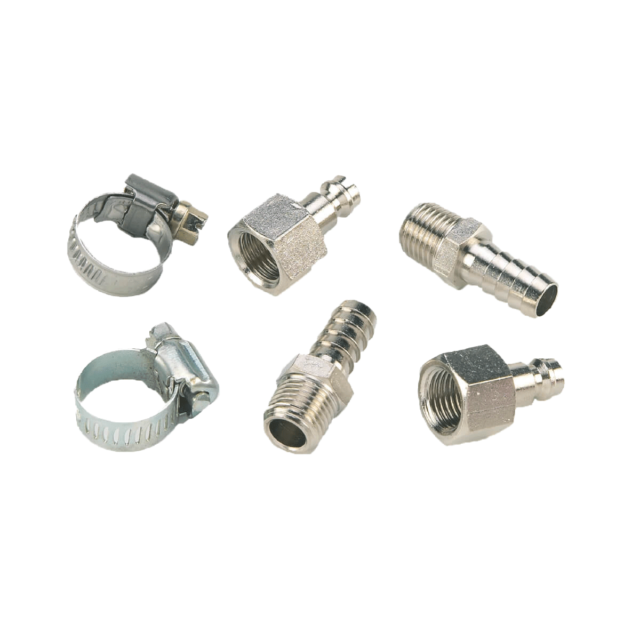

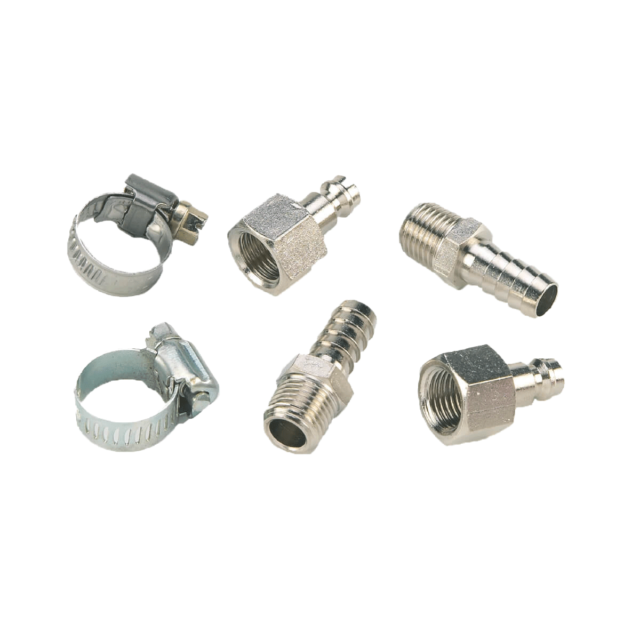

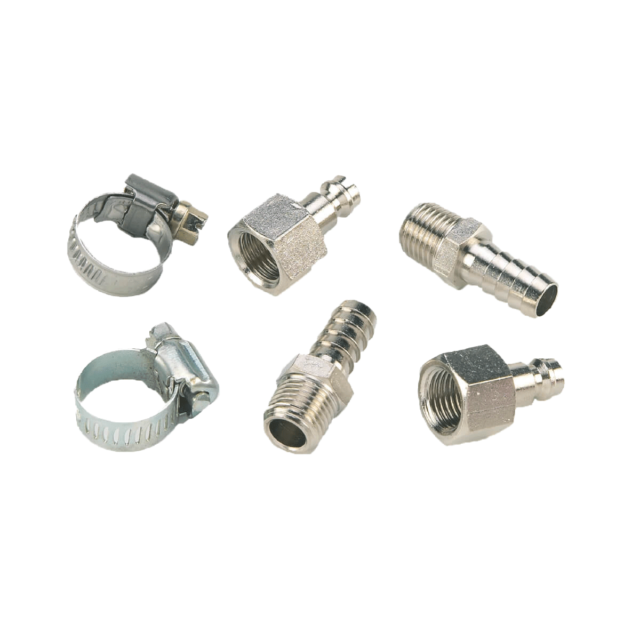

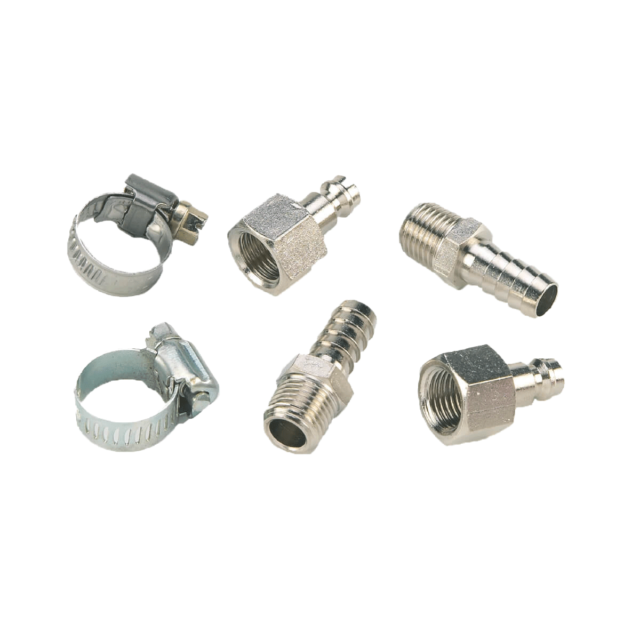

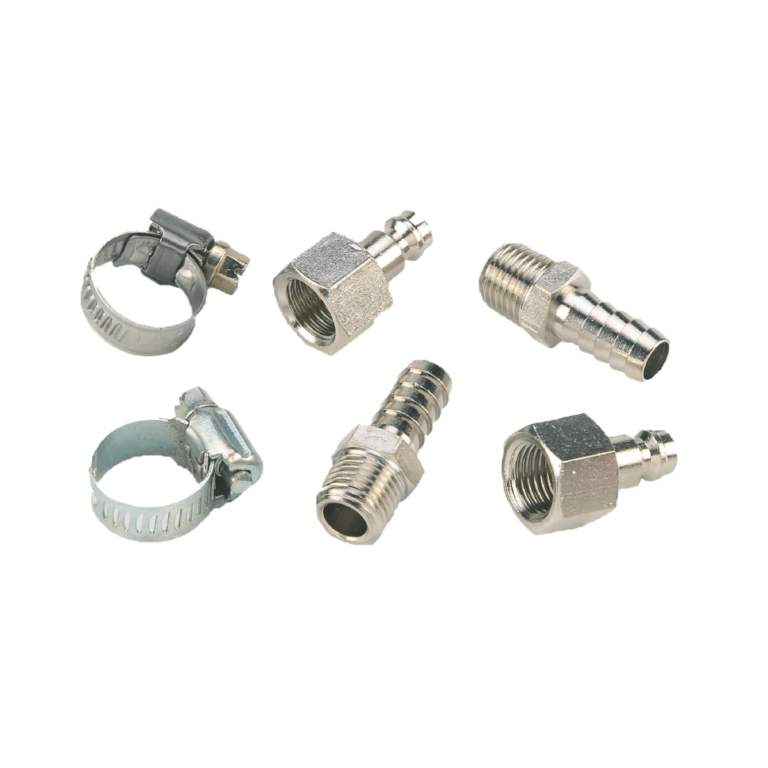

Water cooling connection Kit

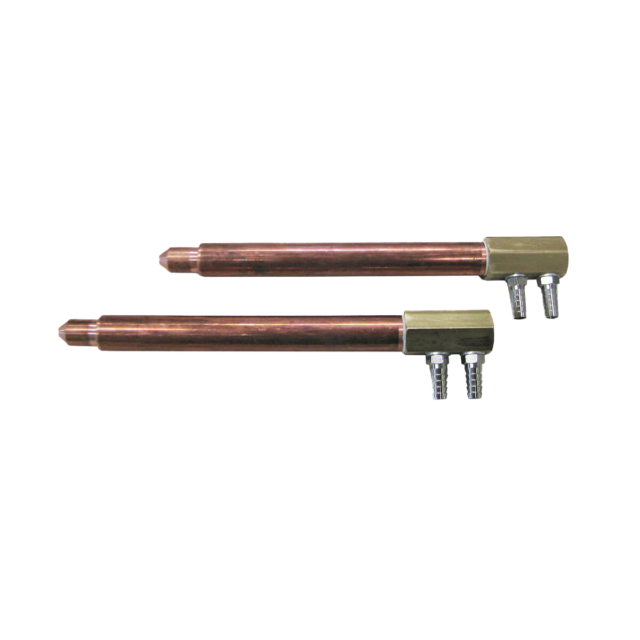

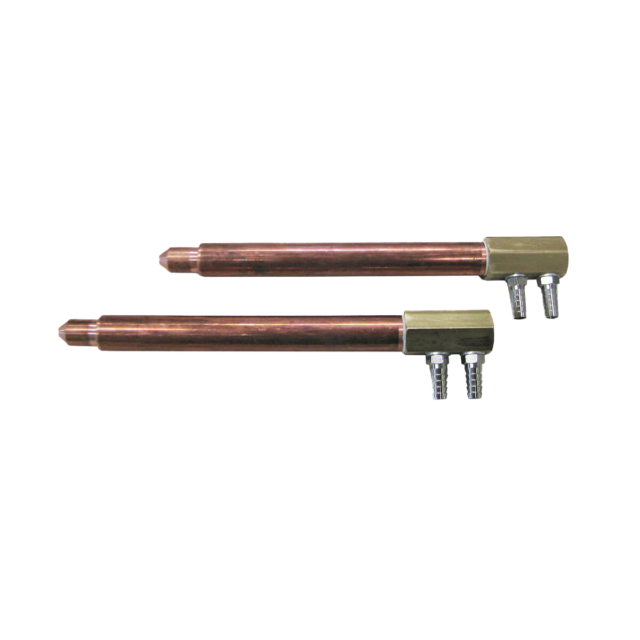

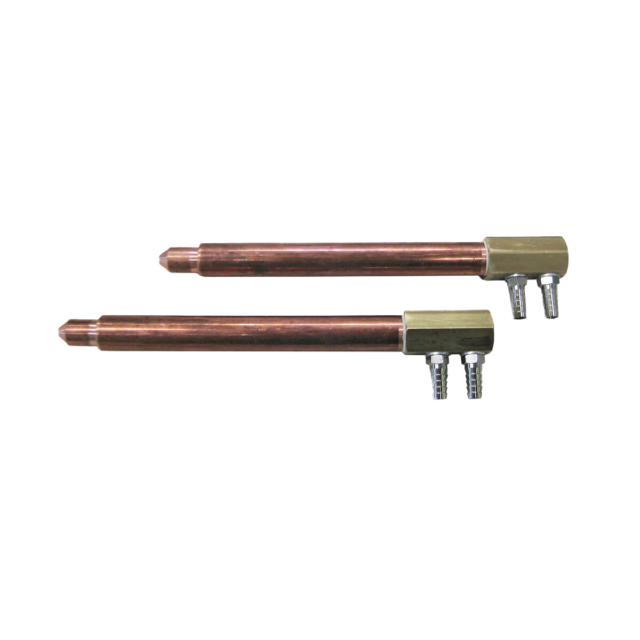

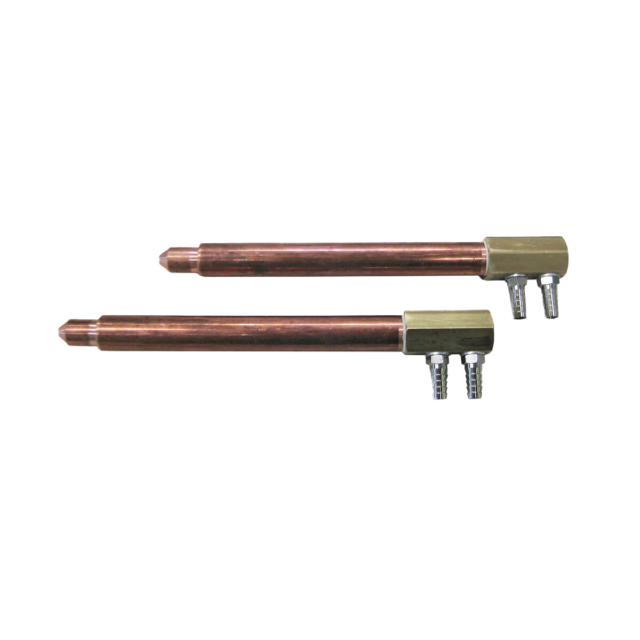

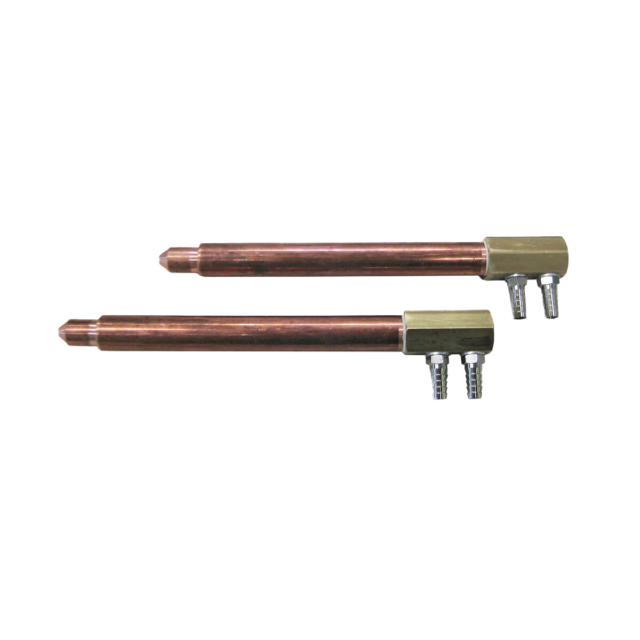

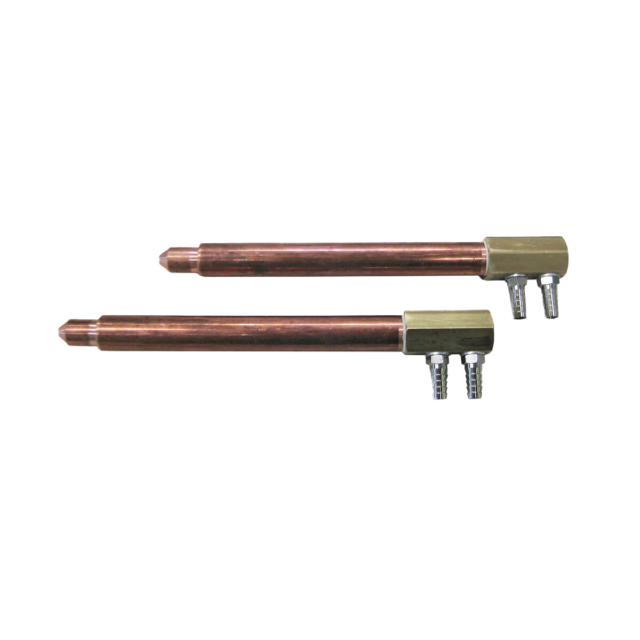

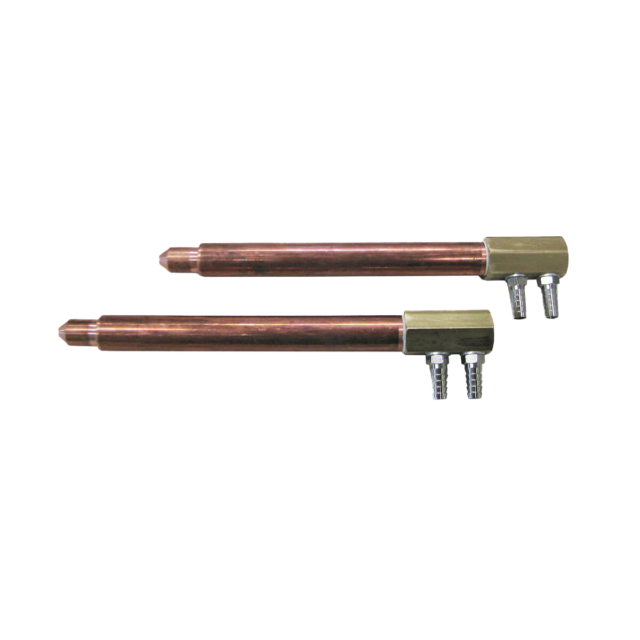

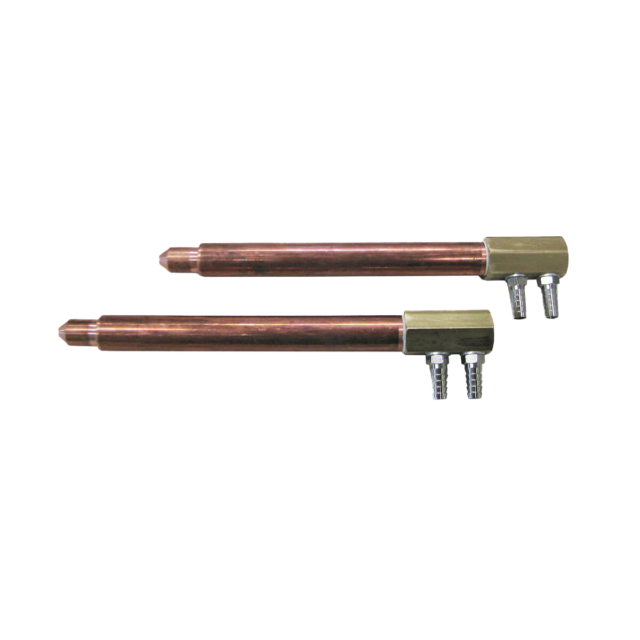

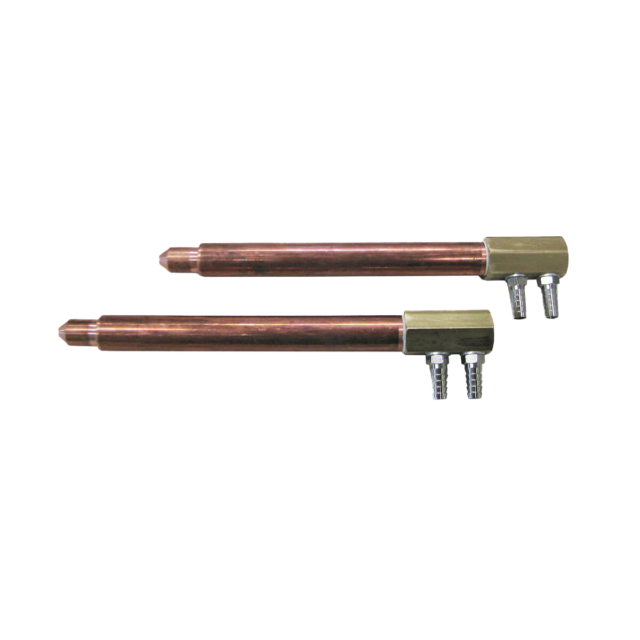

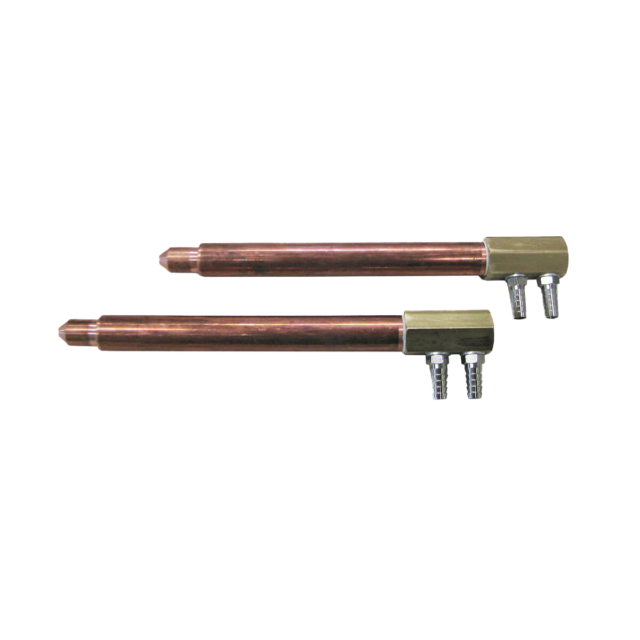

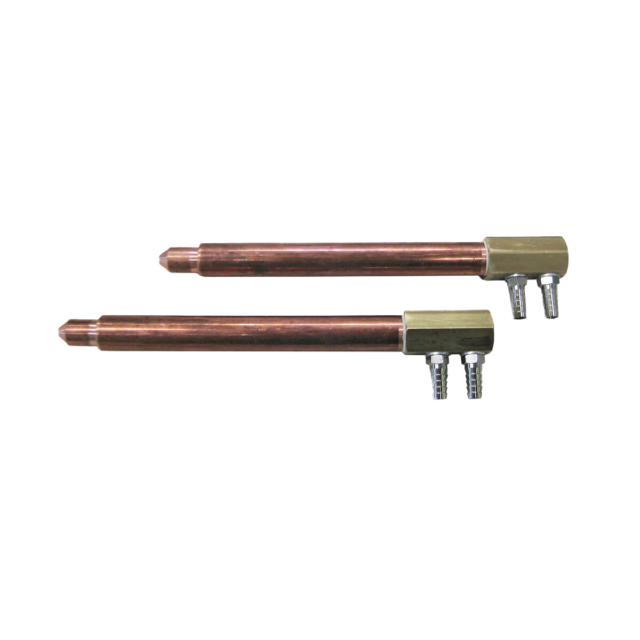

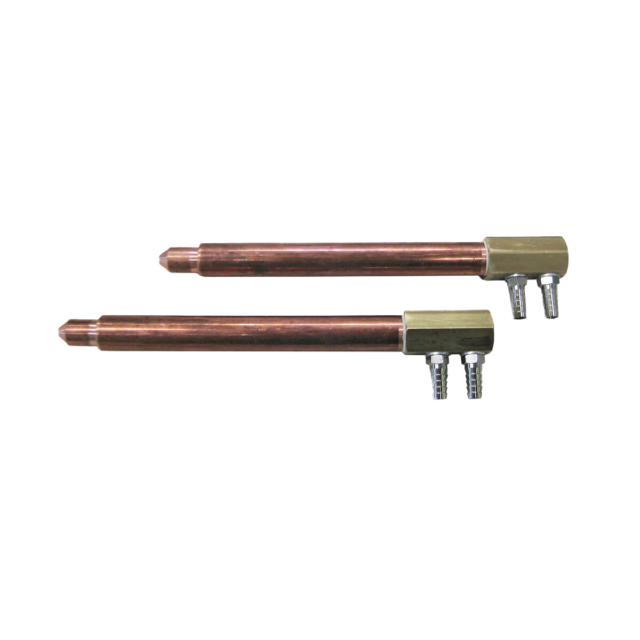

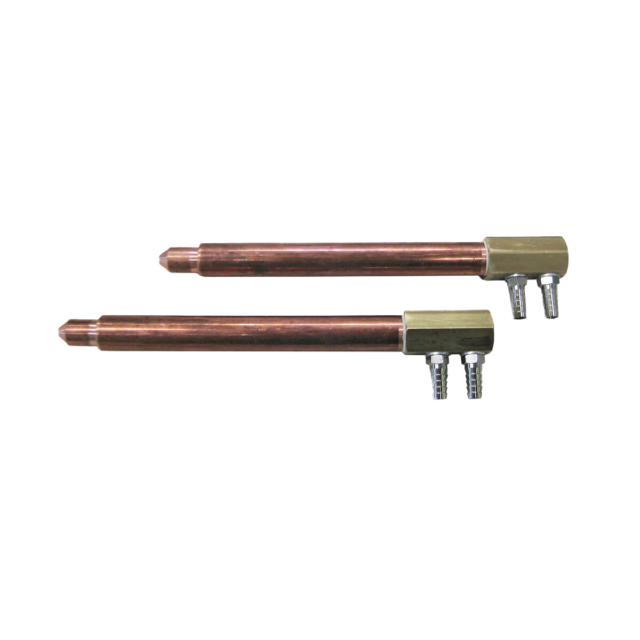

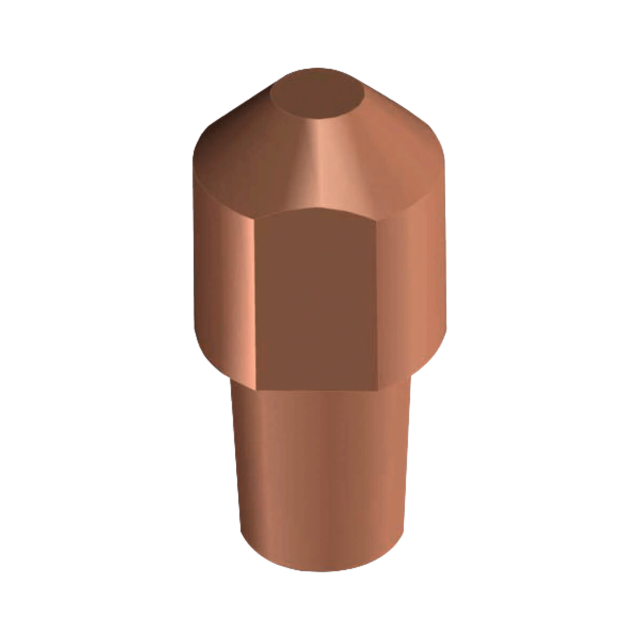

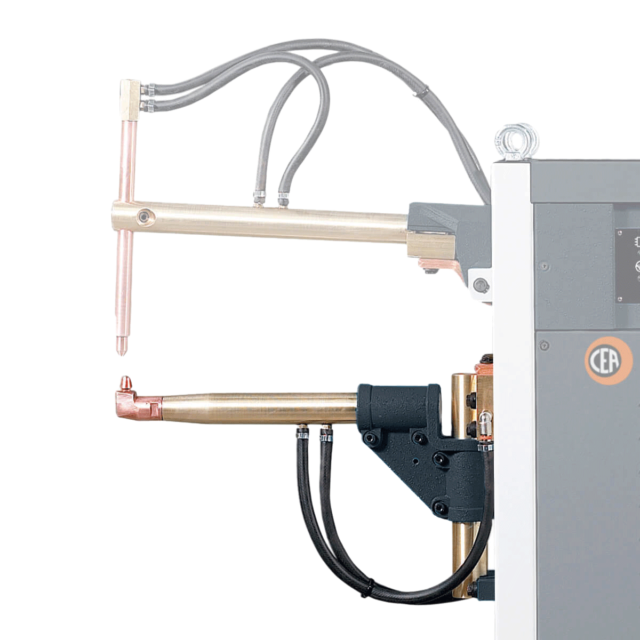

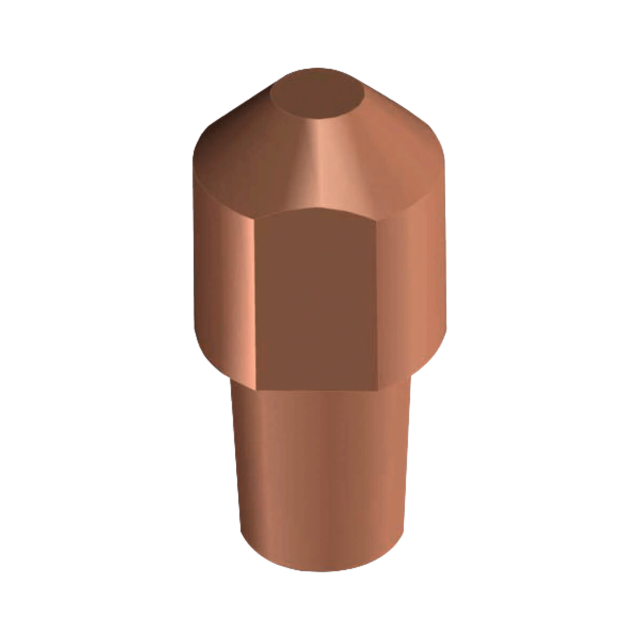

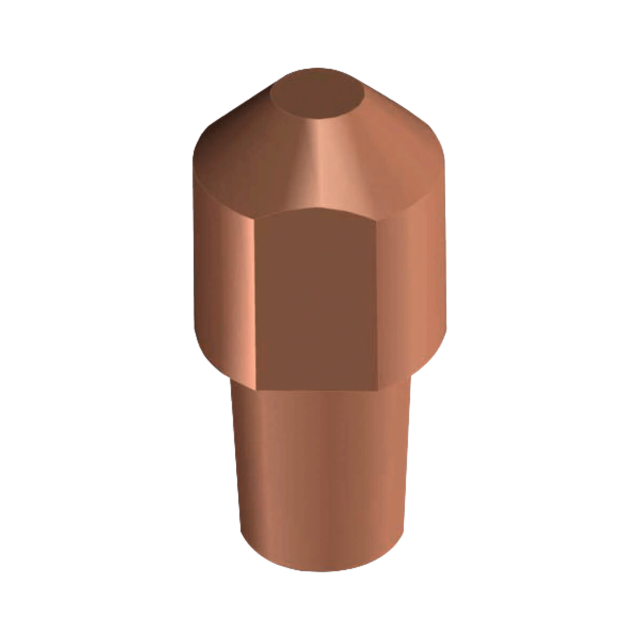

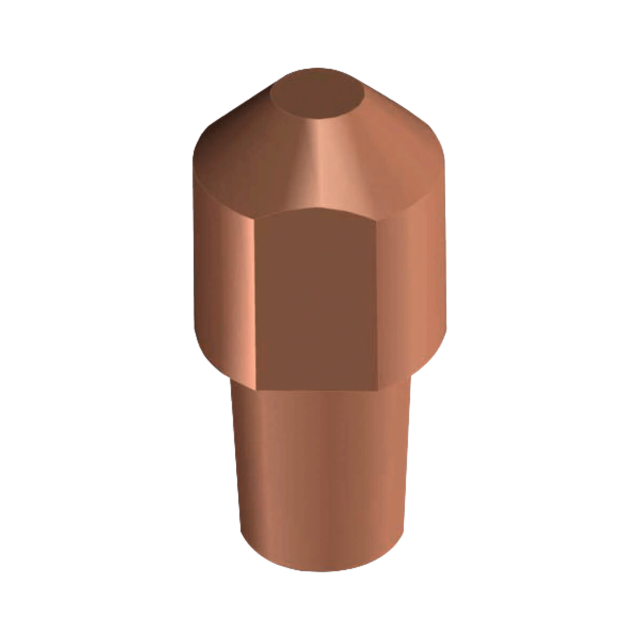

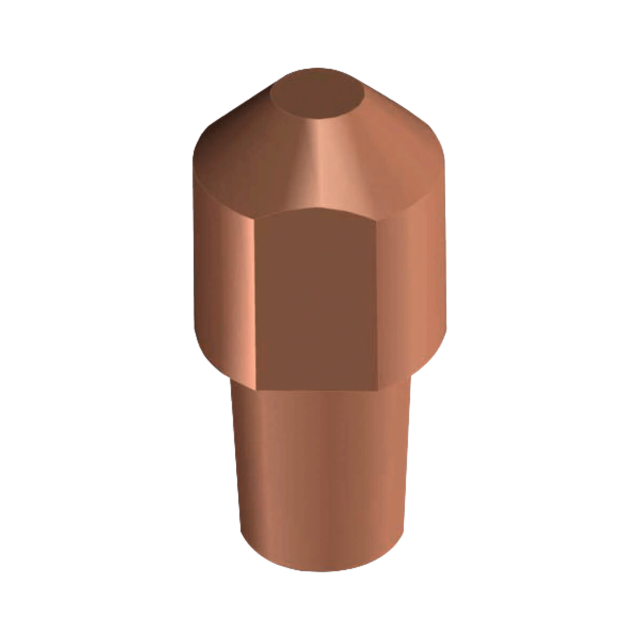

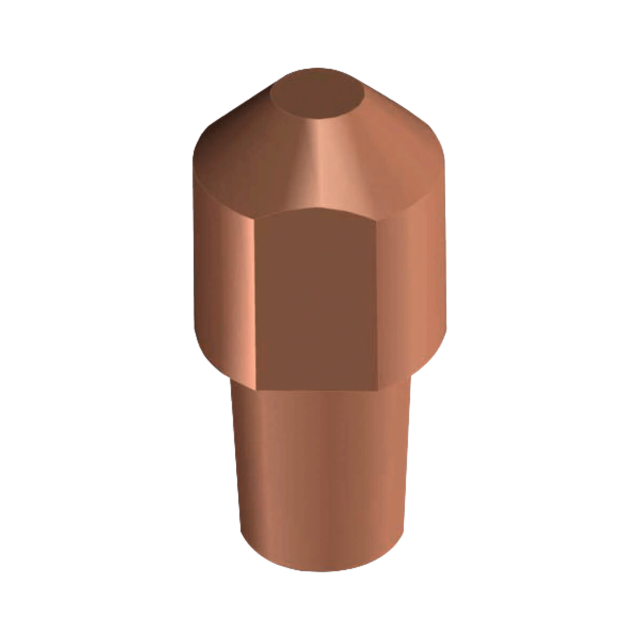

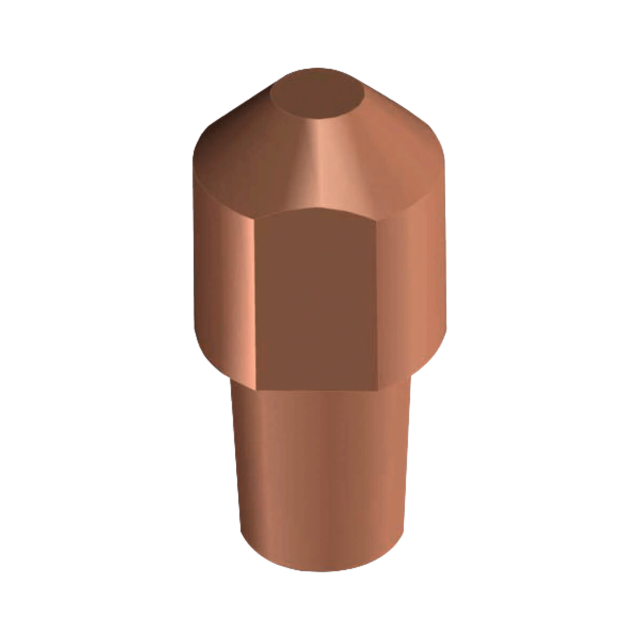

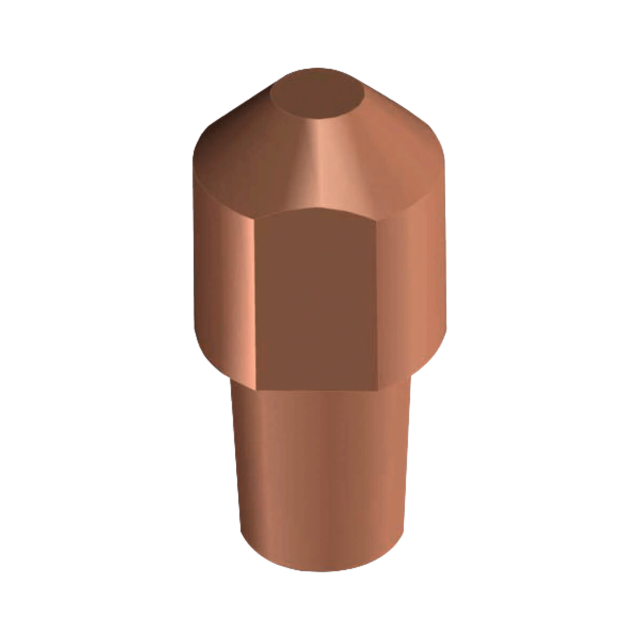

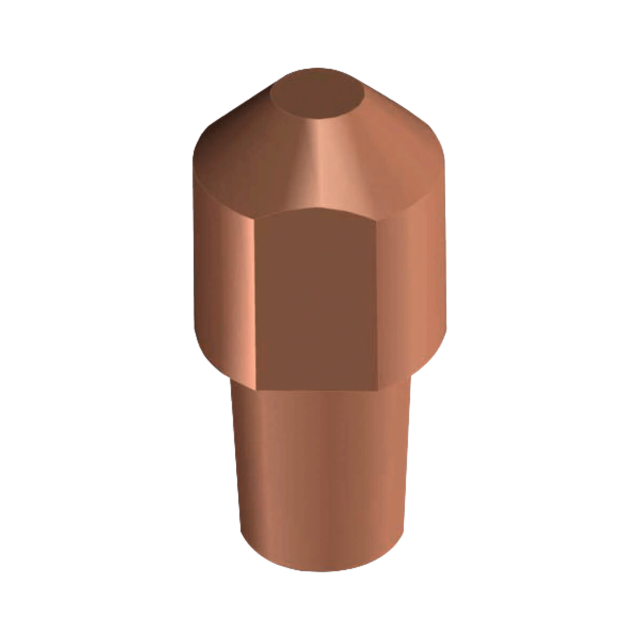

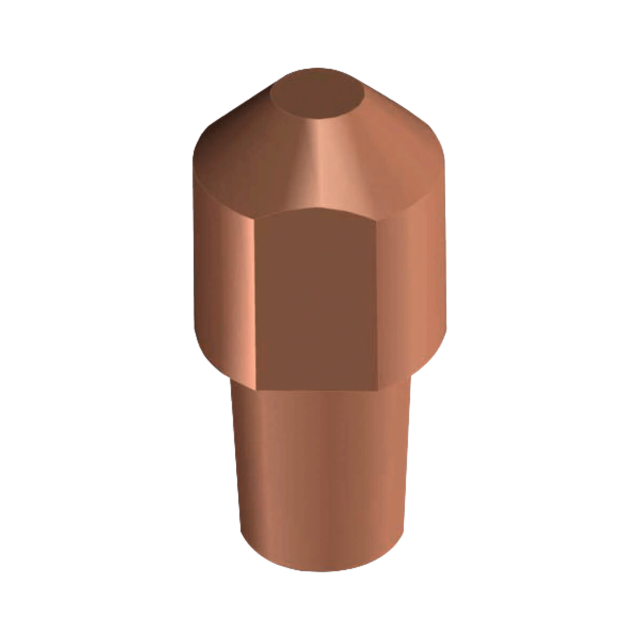

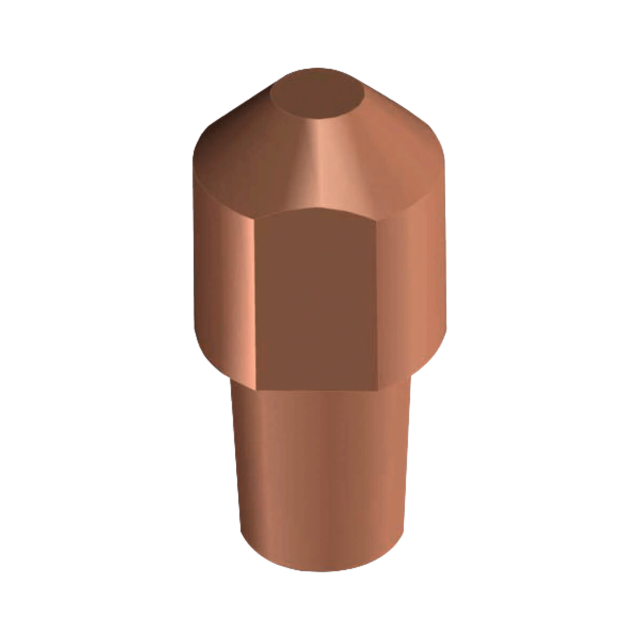

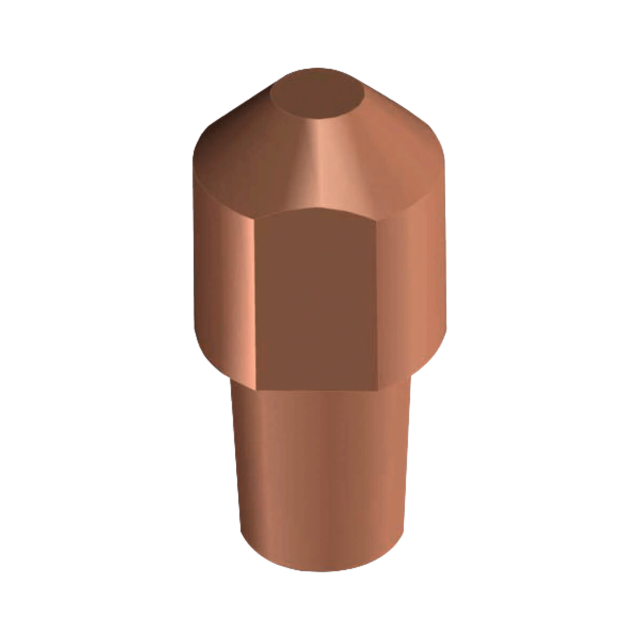

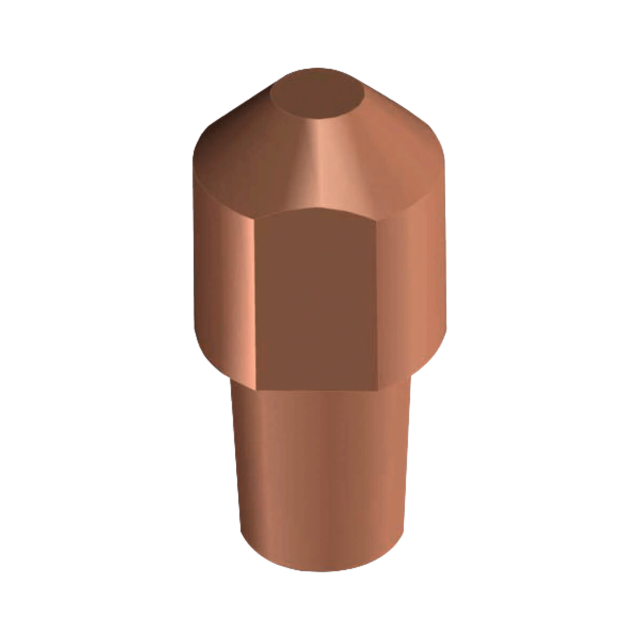

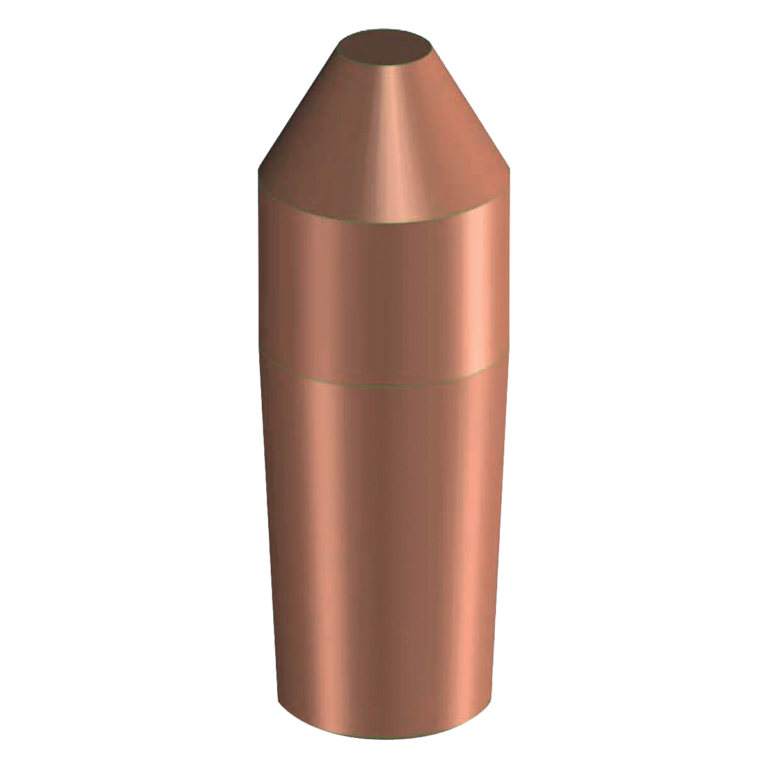

Set electrodeholders with electrodes

Set electrodeholders with electrodes

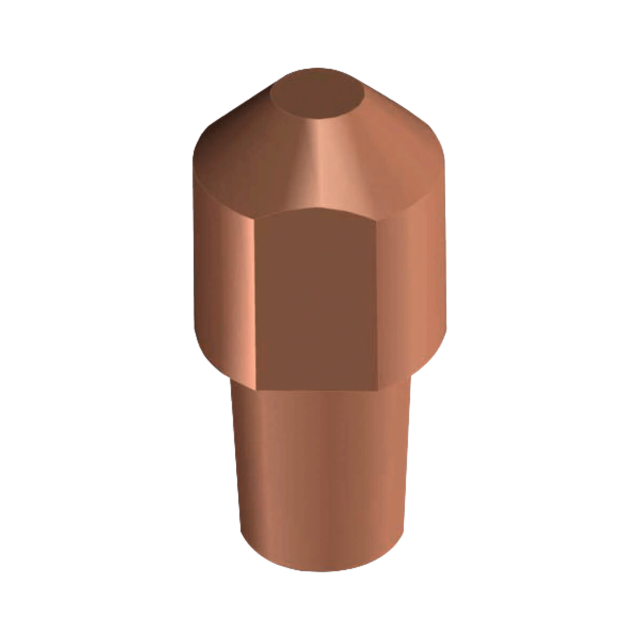

Longer Electrodeholder complete with electrode

Longer Electrodeholder complete with standard electrode

Set of 6 standard electrodes – Ø 16 mm

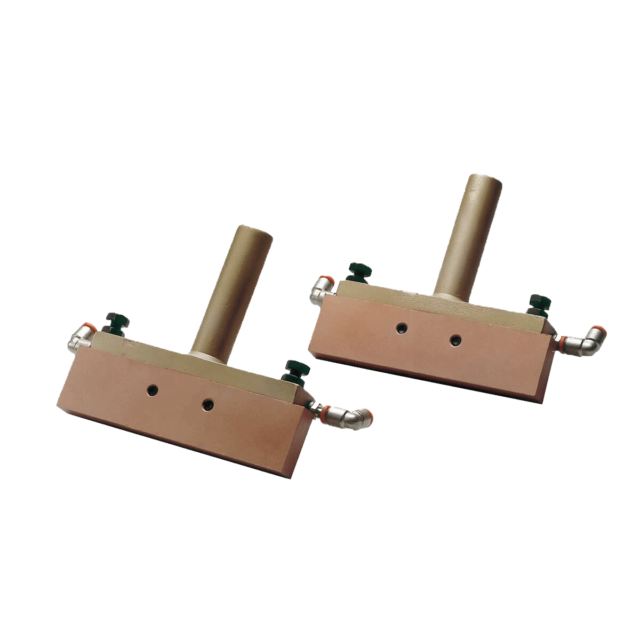

Set of pipe tips with electrodes depth 65 mm

Set of pipe tips with electrodes depth 65 mm

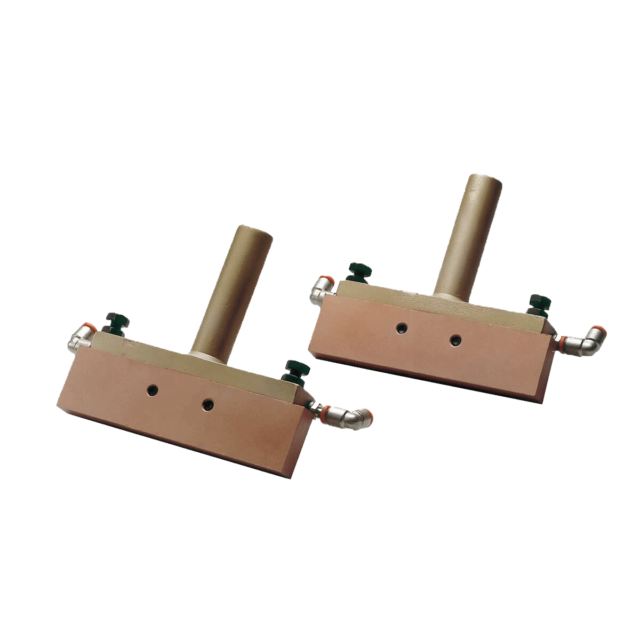

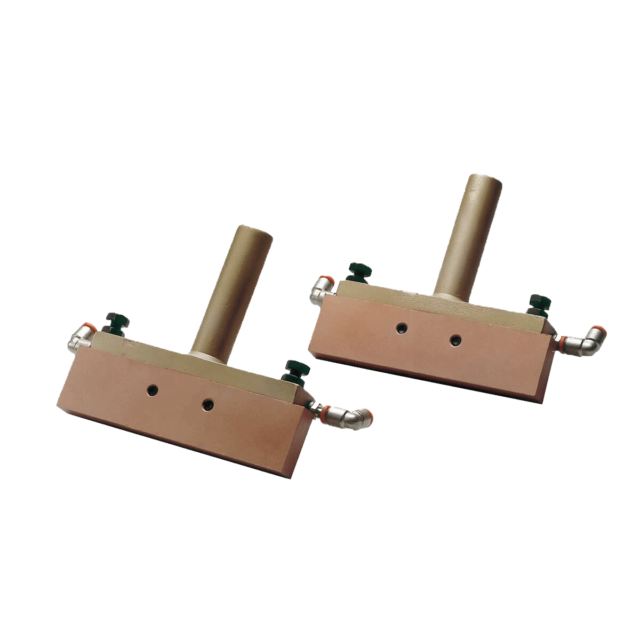

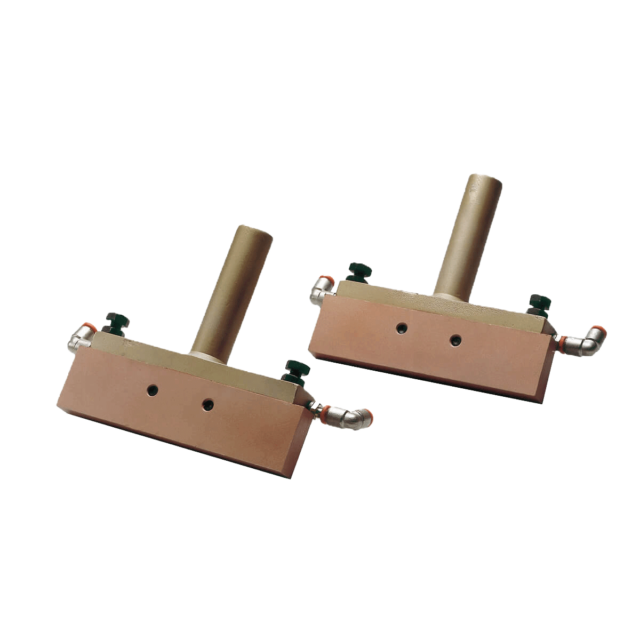

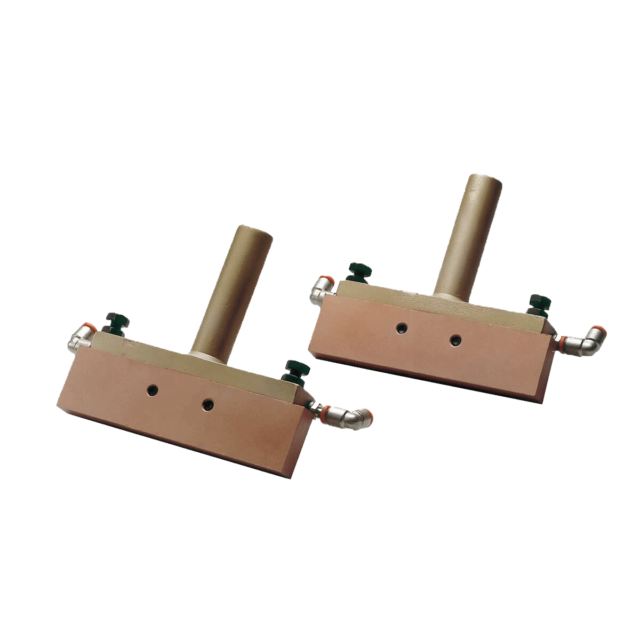

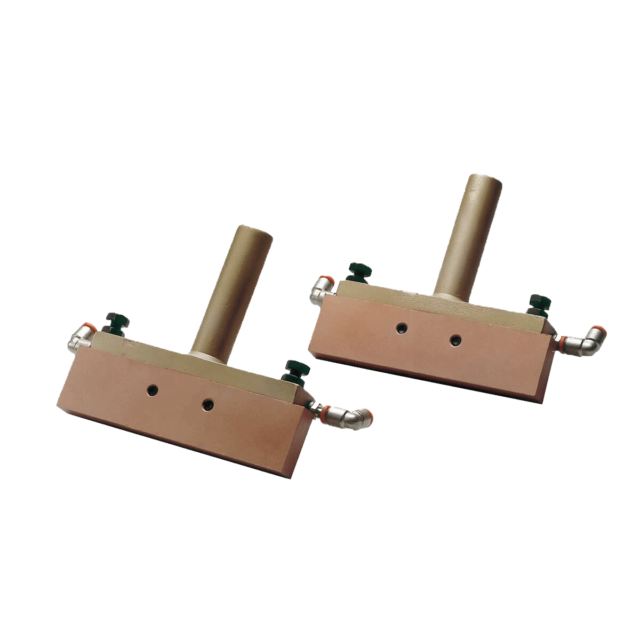

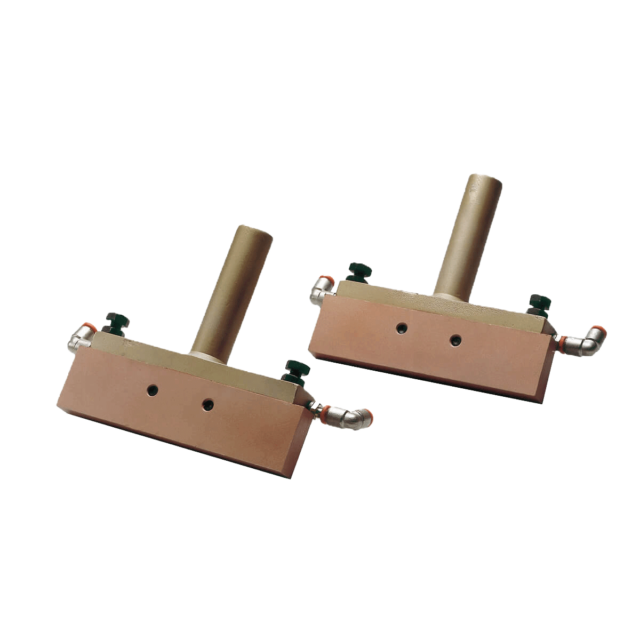

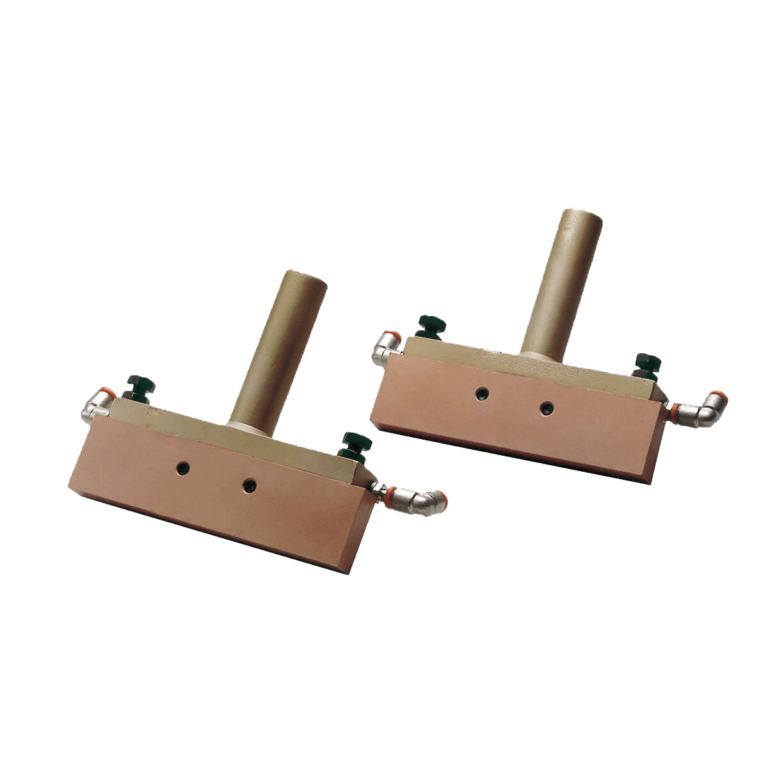

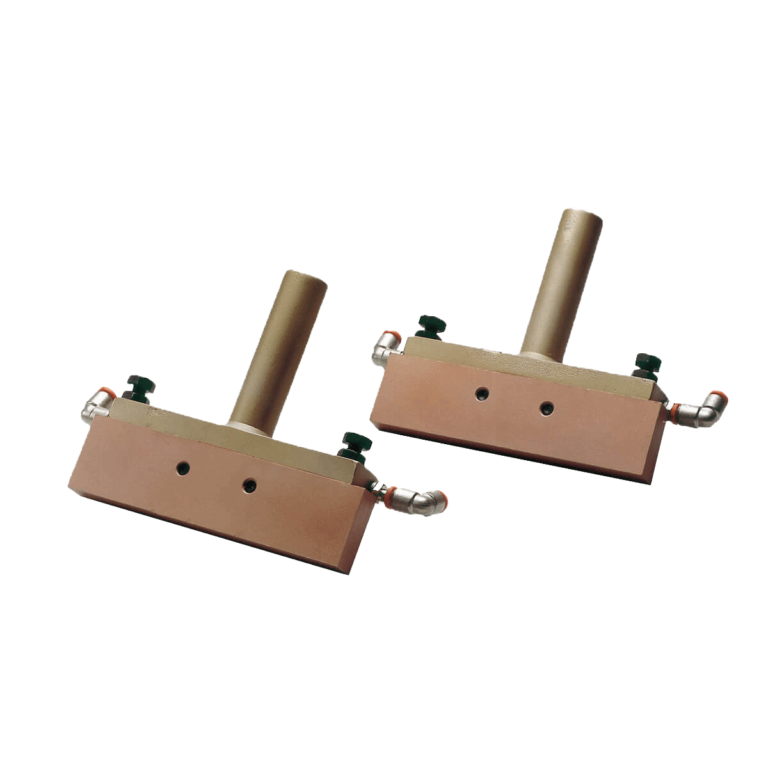

Barholders with 100 mm bars

Barholders with 100 mm bars

Single pedal for welding start

2 pedals (2 times – 2 welding currents)

2 step pedal (1st step: squeeze, 2nd step: welding)

2 double step pedals (2 pedals, boths with: 1st step: squeeze, 2nd step: welding)

| TECHNICAL DATA | K 22

KP 22 |

K 28

KP 28 |

K 48

KP 48 |

|

| Single phase input 50/60 Hz | V | 400 | 400 | 400 |

| Nominal maximum power | kVA | 20 | 25 | 45 |

| Max. welding power | kVA | 36,5 | 54,7 | 75 |

| Installed power | kVA | 12 | 14 | 24 |

| Fuse (delayed action) | A | 25 | 36 | 63 |

| Secondary voltage | V | 3,5 | 4,2 | 5,2 |

| Secondary short circuit current | kA | 11,6 | 14 | 17,8 |

| Max. welding current | kA | 9,3 | 11,2 | 14,2 |

| Electrode force at 600kPa (6bar) | da N | 180 | 300 | 280 |

| Water consumption at 300kPa (3bar) | l/min | 3,8 | 3,8 | 3,8 |

| Dimensions (LxWxH) | mm | 980 x 330 x 1200 | 980 x 390 x 1250 | 1020 x 390 x 1250 |

| Weight | kg | 120 | 167 | 194 |

| K 22

KP 22 |

K 28

KP 28 |

K 48

KP 48 |

||

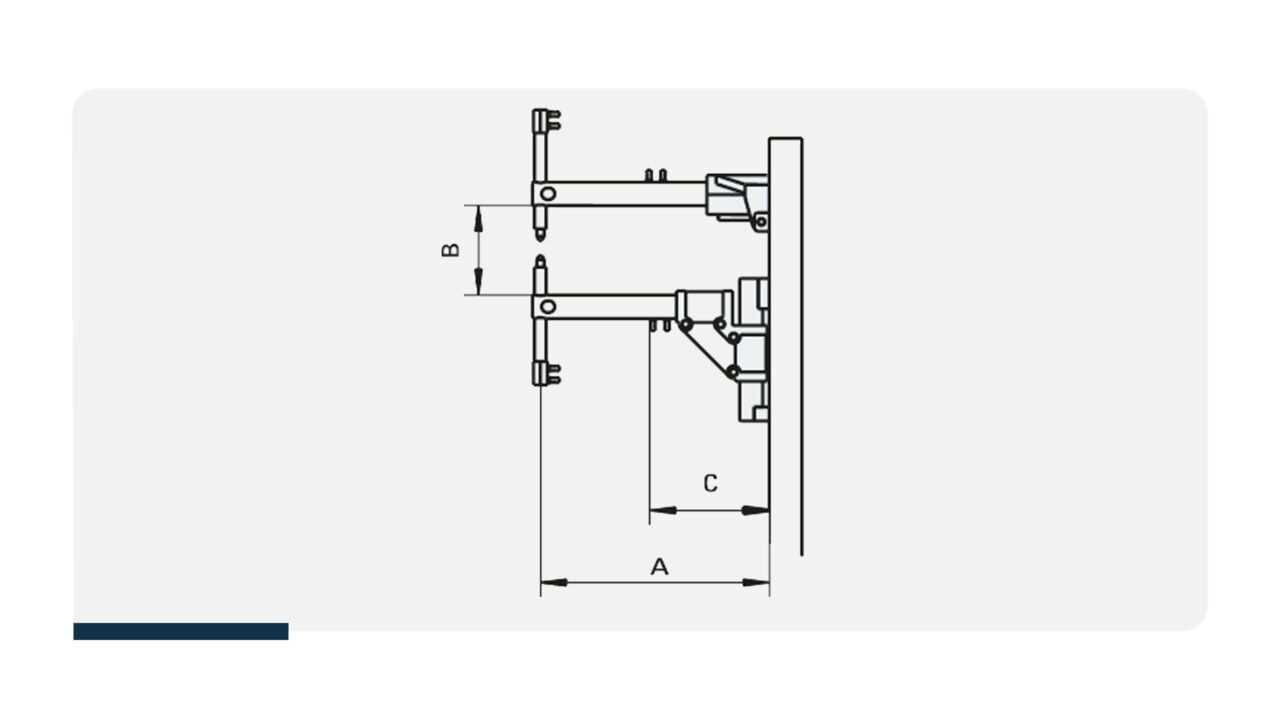

| A | mm | 455 | 455 | 490 |

| A (Optional) | mm | 600 | 600 | 700 |

| mm | 800 | 800 | 1000 | |

| B – MIN | mm | 173 | 168 | 163 |

| B – MAX | mm | 410 | 443 | 438 |

| C | mm | 255 | 255 | 285 |

|

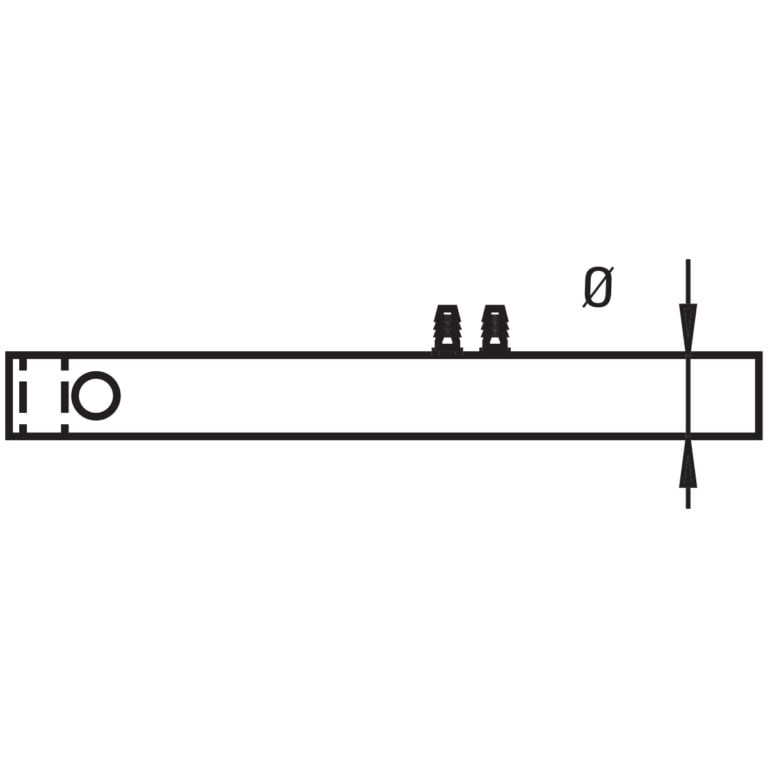

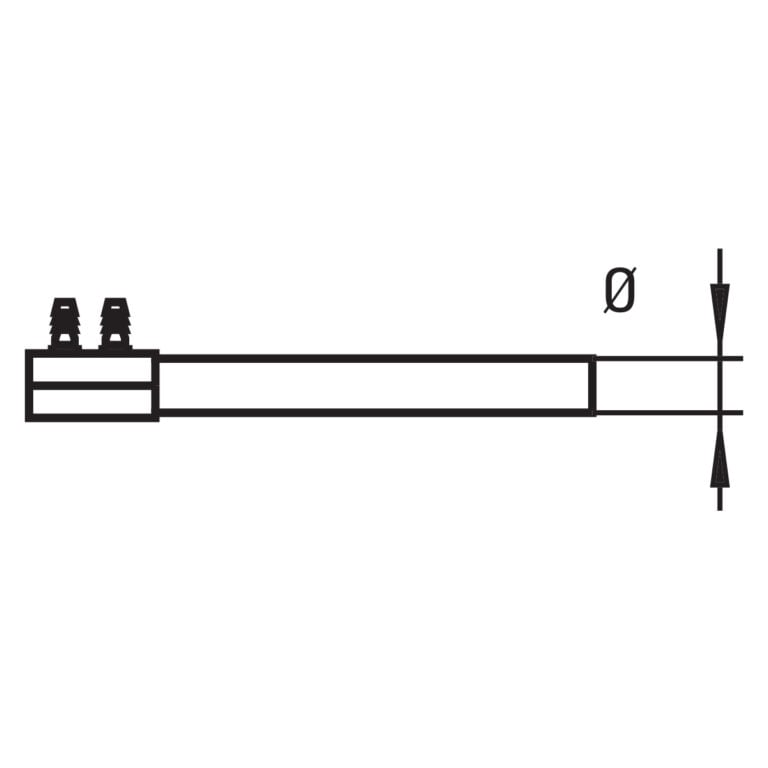

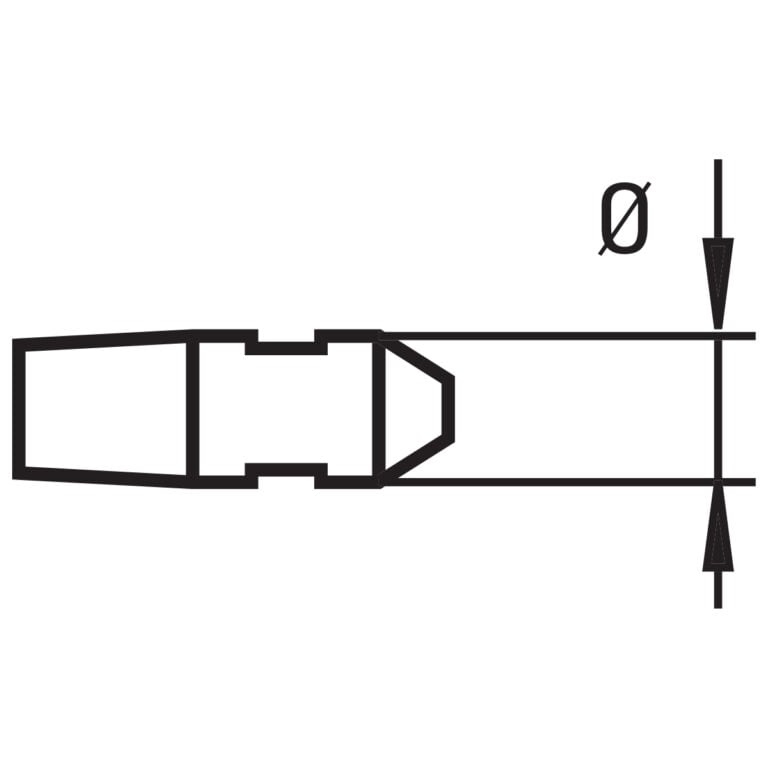

Ø mm | 40 | 45 | 50 |

|

Ø mm | 21 | 21 | 25 |

|

Ø mm | 16 | 16 | 16 |

| 10% | 10% | 10% |

| K 22

KP 22 |

K 22

KP 22 |

K 28

KP 28 |

K 28

KP 28 |

K 48

KP 48 |

K 48

KP 48 |

K 48

KP48 |

||

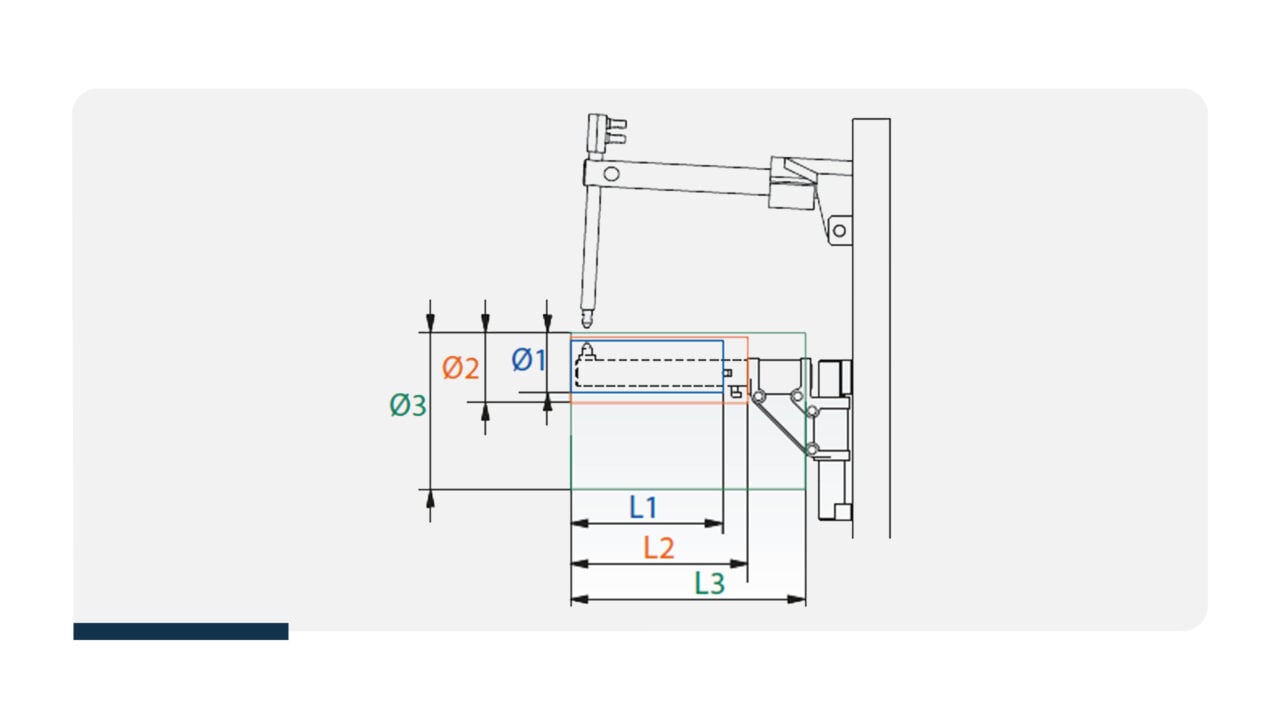

| A | mm | 455 | 600 | 455 | 800 | 490 | 700 | 1000 |

| L1 | mm | 252 | 397 | 252 | 597 | 257 | 467 | 767 |

| Ø1 Min | mm | 60 | 60 | 63 | 63 | 65 | 65 | 65 |

| L2 | mm | 280 | 429 | 289 | 643 | 295 | 505 | 805 |

| Ø2 Min | mm | 85 | 85 | 90 | 90 | 98 | 98 | 98 |

| L3 | mm | 397 | 542 | 402 | 747 | 427 | 637 | 937 |

| Ø3 Min | mm | 180 | 180 | 185 | 185 | 205 | 205 | 205 |